I j k integrand words – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 306

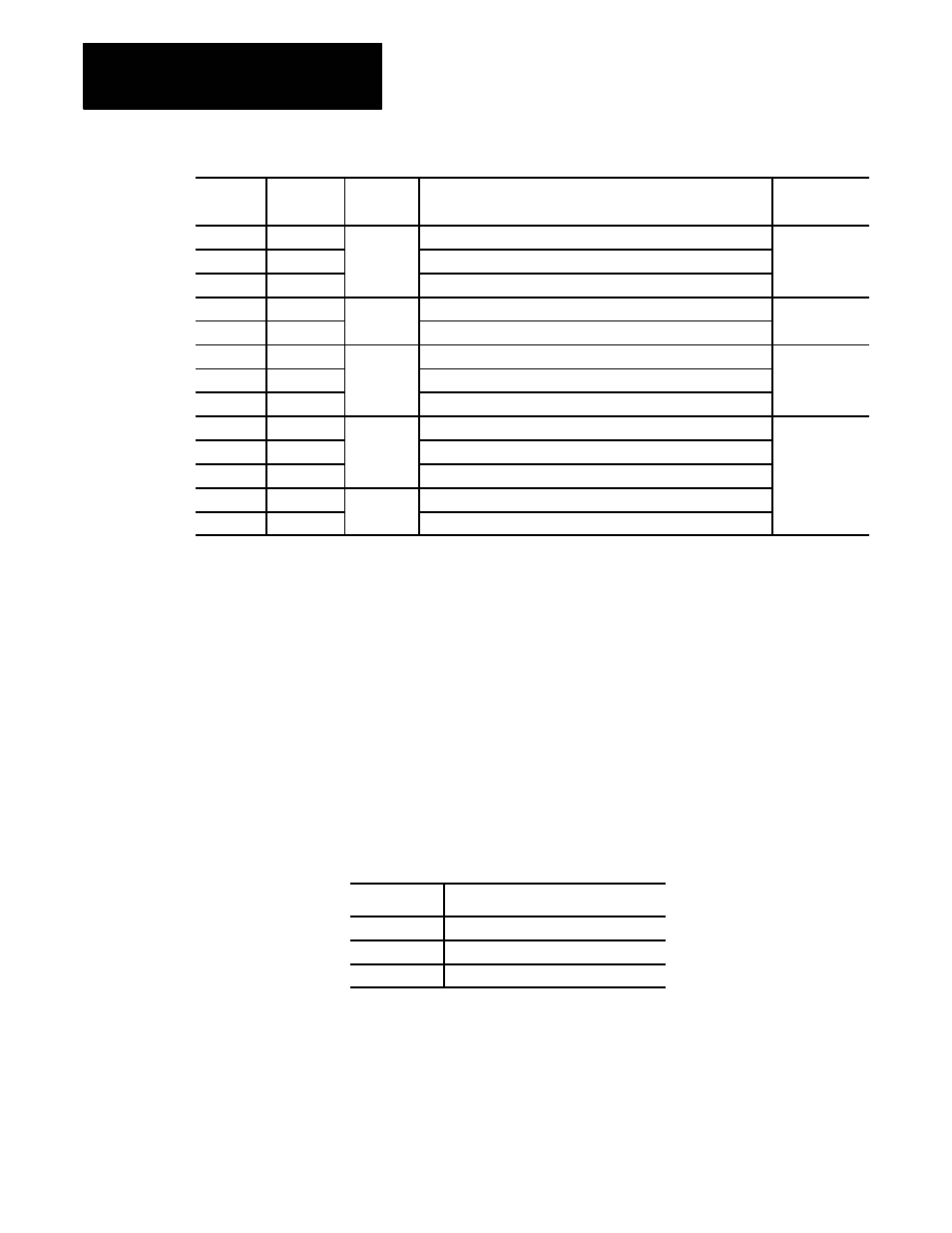

Introduction to Programming

Chapter 10

10-28

Surface

Grinder

Modal or

Non-modal

Function

Group

Number

Cylindrical

Grinder

-- --

G88.1

09

Diameter plunge shoulder cycle with predress

-- --

G89

Multi-step plunge with blend

-- --

G89.1

Multi-step plunge with blend and predress

G90

G90

03

Absolute mode

Modal

G91

G91

Incremental mode

G92

G92

00

Maximum CSS spindle RPM, coordinate offset

Non-modal

G92.1

G92.1

Cancel offsets

G92.2

G92.2

Cancel select offsets and G92 presets

G93

G93

05

Inverse time feedrate mode

Modal

G94

G94

Feed per minute feedrate mode

G95

G95

Feed per revolution feedrate mode

G96

G96

17

Constant surface speed on

G97

G97

RPM spindle speed mode (CSS off)

A set of default G codes becomes effective at power-up, when the control

is reset, or an emergency stop condition is reset. These default G codes are

selected by your system installer in AMP. They can be seen on the status

display screen after power-up or control reset.

Integrand words are typically used to define parameters that relate to a

specific axis for a fixed cycle, or circular motion block; however, they are

not limited to use only in these operations. For example, in circular motion

blocks the axis integrands are used to define the center point of an arc or

circle.

Your system installer has the option of assigning either I, J, K, or none as

the axis integrand name for a specific axis. This manual assumes the

following:

Assign:

To the integrand name for the:

I

X axis

J

Y axis

K

Z axis

Important: See your system installer’s documentation to make sure these

assumptions are true. If not, it is important that the programmer realize

that all examples and formats in this manual that use an I, J, K need to

have their letter replaced with the correct integrand word for your system.

10.5.5.

I J K Integrand Words