Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 667

Paramacros

Chapter 20

20-23

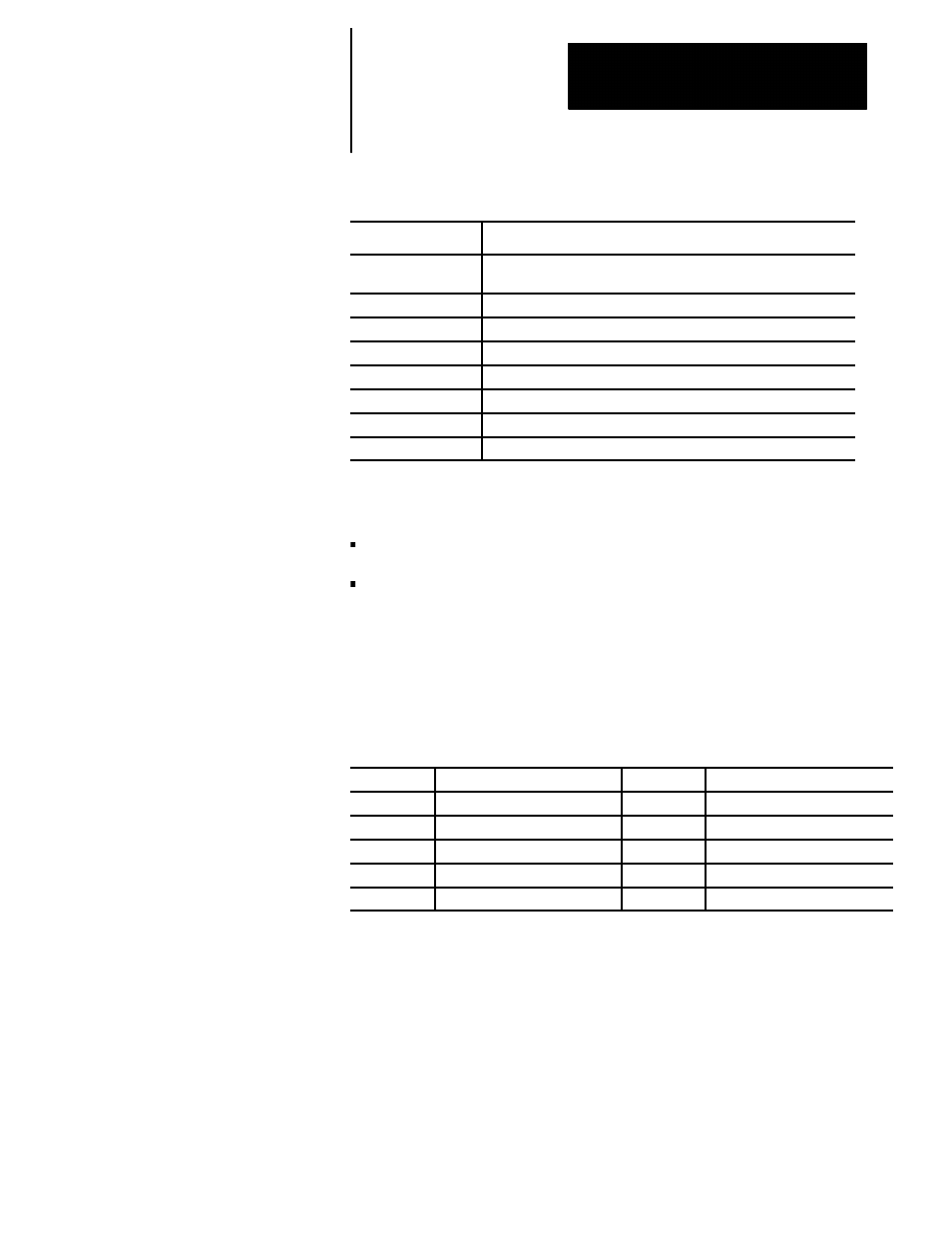

Table 20.G

Modal Data Parameters

Parameter Number

Modal Data Value

#4001 to 4021

G-code Groups 1-21 (see page 20-54) and list what G-code from

which group is currently active.

4108

Current E word value

4109

Current F word value

4113

Most recently programmed M-code

4114

Most recently programmed N word

4115

Current program number O word

4119

Current S word value

4120

Current T word value

For example, if currently programming in G02 mode at a feedrate of 100,

the parameters are as follows:

G02 is in G-code group 1, so parameter #4001 is set to 02

the programmed feedrate is F100, so parameter #4109 is set to 100

#5001 to 5012

Coordinates of End Point

These parameters are read-only. They correspond to the coordinates of the

end point (destination) of a programmed move. These are the coordinates

in the work coordinate system.

5001

Axis 1 coordinate position

5007

Axis 7 coordinate position

5002

Axis 2 coordinate position

5008

Axis 8 coordinate position

5003

Axis 3 coordinate position

5009

Axis 9 coordinate position

5004

Axis 4 coordinate position

5010

Axis 10 coordinate position

5005

Axis 5 coordinate position

5011

Axis 11 coordinate position

5006

Axis 6 coordinate position

5012

Axis 12 coordinate position

The system installer determines in AMP the name (or word) that is used to

define the axis.