Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 491

Dresser/Wheel Radius Compensation

Chapter 15

15-3

Dresser/wheel radius compensation also uses dresser/wheel orientation

data. You need orientation data:

to compensate for inaccuracies that can occur from difficulties in

measuring wheel corner and dresser radius because of mounting

position

and

to tell the control which edge of the dresser/wheel you intend to use

when dressing or grinding

If the above is not a factor, make sure all orientations use an orientation of

0 or 9.

Enter the radius and orientation data into the offset tables before

attempting to activate any compensation. See chapter 3 for details on

entering offset table data.

Types of Dresser/Wheel Radius Compensations

Two types of dresser/wheel radius compensation are available on the

control:

type A (as described on page 15-17)

type B (as described on page 15-27)

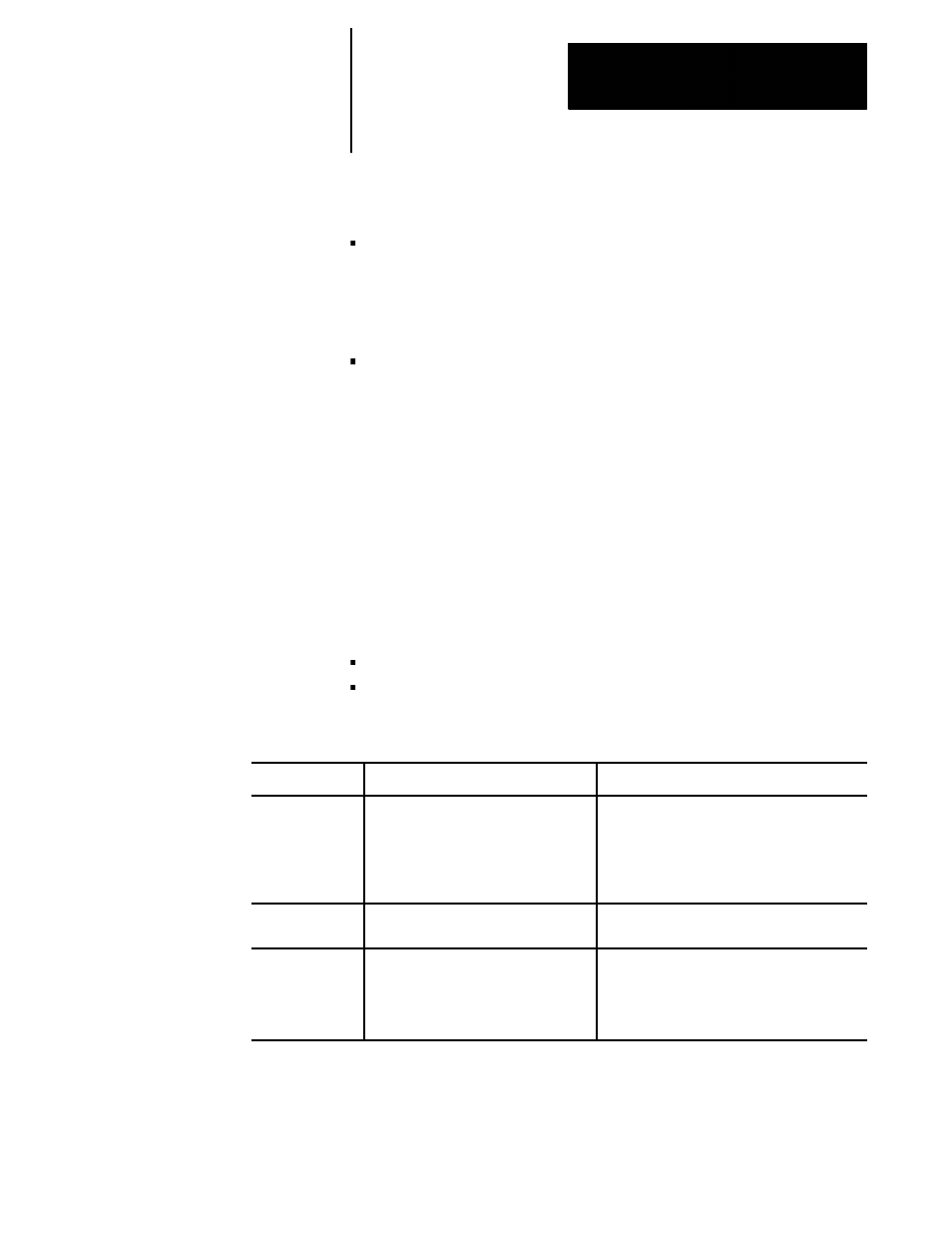

The following table highlights the differences between the two types:

Type of Move

Type A

Type B

Entry Move Into

compensation

The dresser/wheel takes the shortest

possible path to its offset position.

The dresser/wheel stays at least one radius away

from the start-point of the next block at all times.

Extra motion blocks can be generated to attempt

to prevent gouging of the part as can occur in

Type A.

Dresser/wheel

Path

Same as Type B.

Same as Type A.

Exit Move From

compensation

The dresser/wheel takes the shortest path

to the end-point of the exit move for both

inside and outside corners.

The dresser/wheel takes the shortest path to the

end-point of exit move for inside corners only.

For outside corners, the dresser/wheel stays at

least one radius away from the end-point.

Your system installer determines in AMP whether your control uses type A

or type B compensation.