3 system parameters – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 660

Paramacros

Chapter 20

20-16

You can use system parameters in any part program, including paramacros

and subprograms. All of these parameters can be used as data or can be

changed by assignment (read and write) unless indicated differently in

Table 20.D. System parameters are generated by the control and can be

modified by operation or programming.

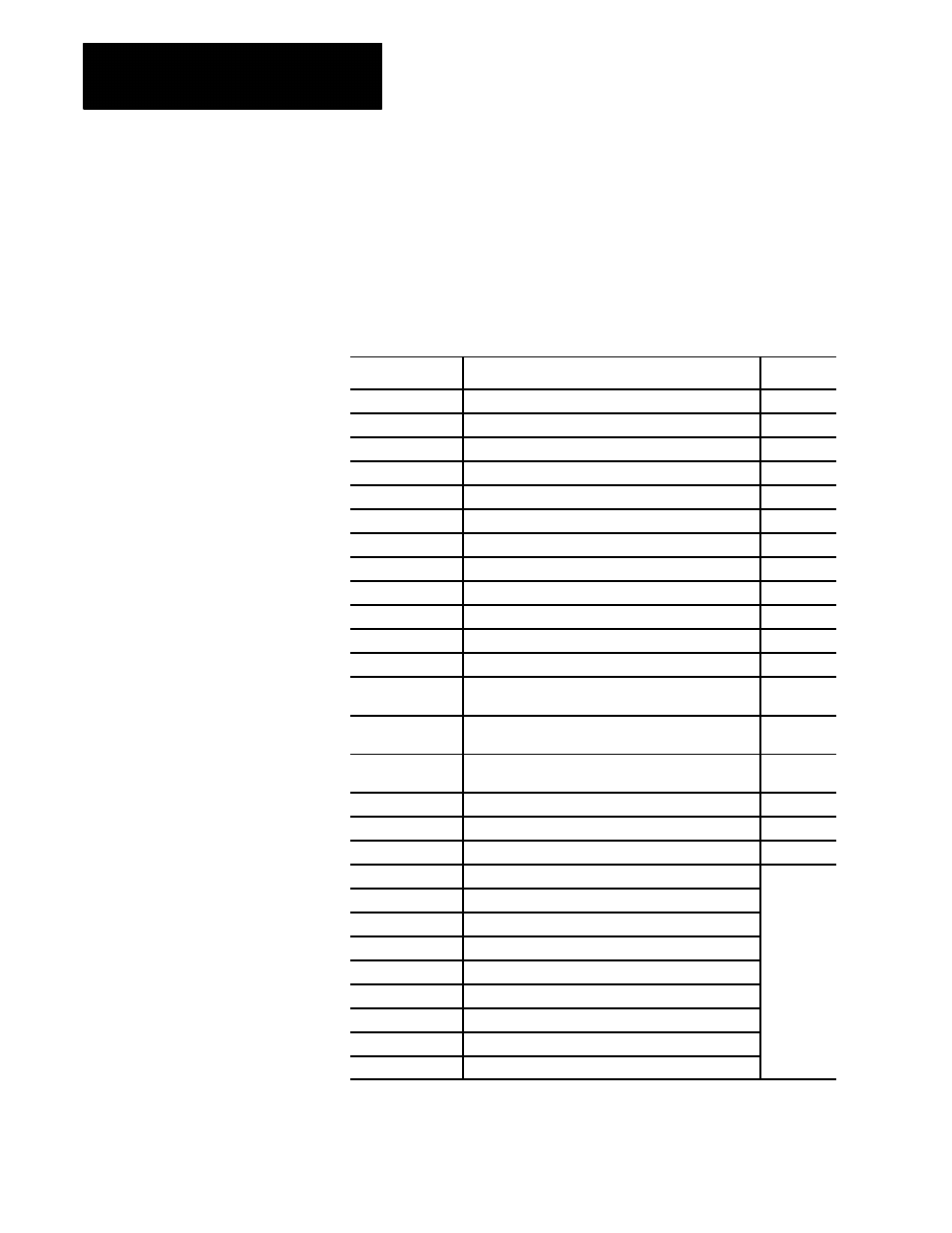

Table 20.D

System Parameters

Parameter #

System Parameter

Page

2001 to 2732

Dresser/Wheel Offset Tables

20-18

3000

2

Program Stop With Message (PAL)

20-18

3001

System Timer (PAL)

20-19

3002

System Clock

20-19

3003

2

Block Execution Control 1

20-19

3004

2

Block Execution Control 2

20-20

3006

2

Program Stop With Message

20-21

3007

1

Mirror Image

20-22

4001 to 4120

1

Modal Information

20-22

5001 to 5012

1

Coordinates of End Point

20-23

5021 to 5032

1

Coordinates of Commanded Position

20-24

5041 to 5052

1

Machine Coordinate Position

20-24

5061 to 5069 or

5541 to 5552

1

Skip Signal Position (Work Coordinate)

20-25

5071 to 5079 or

5561 to 5572

1

Skip Signal Position (Machine Coordinates)

20-26

5081 to 5089 or

5581 to 5592

1

Active Tool Length Offsets

20-27

5095 to 5096

1

Probe Length and Radius

20-28

5101 to 5112

1

Current Following Error

20-29

5201 to 5212

External Offset amount

20-29

5221 to 5232

G54 Work Coordinate Table Value

20-30

5241 to 5252

G55 Work Coordinate Table Value

5261 to 5272

G56 Work Coordinate Table Value

5281 to 5292

G57 Work Coordinate Table Value

5301 to 5312

G58 Work Coordinate Table Value

5321 to 5332

G59 Work Coordinate Table Value

5341 to 5352

G59.1 Work Coordinate Table Value

5361 to 5372

G59.2 Work Coordinate Table Value

5381 to 5392

G59.3 Work Coordinate Table Value

20.3.3

System Parameters