Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 332

Coordinate Control

Chapter 11

11-16

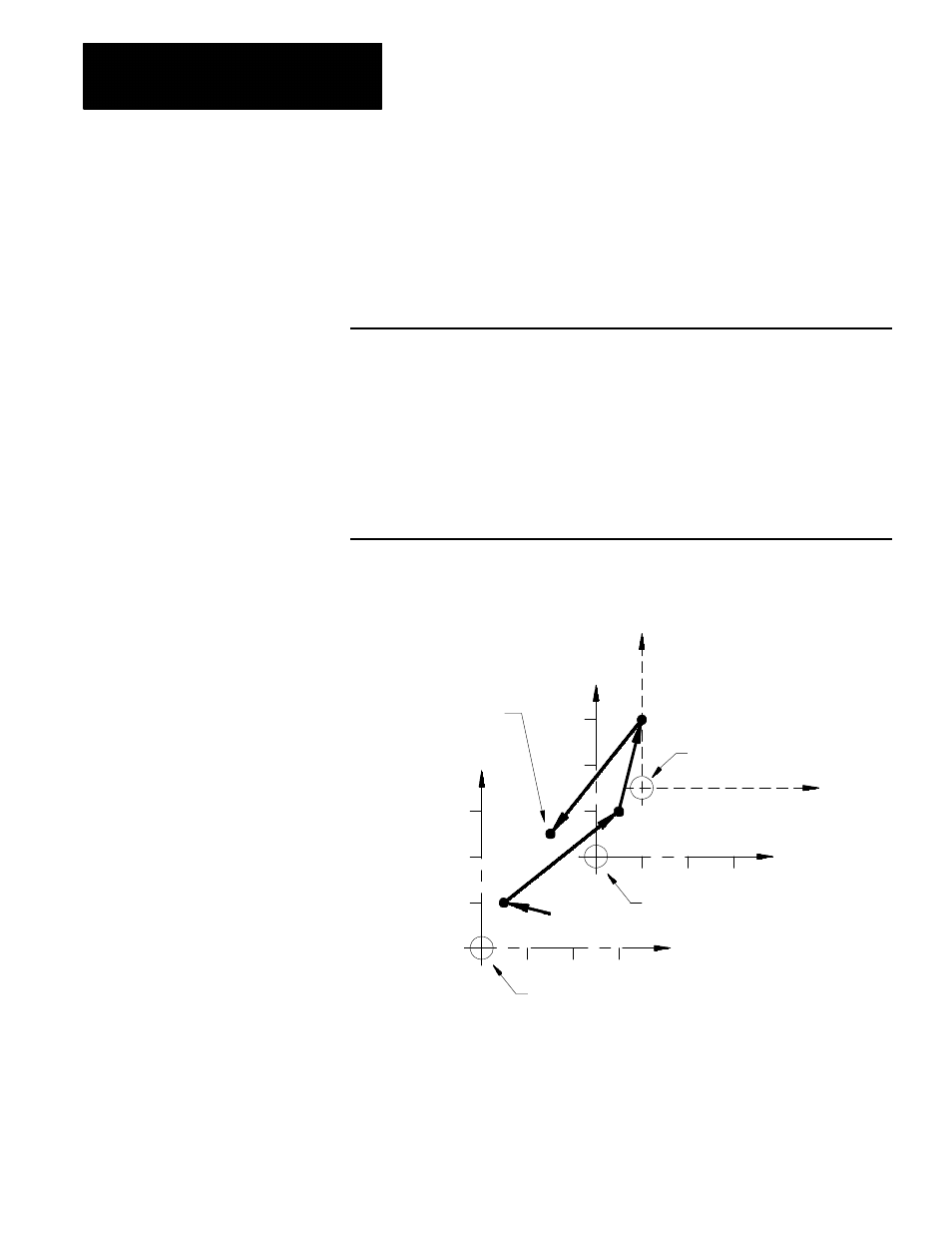

Example 11.6 shows the effect of changing work coordinate systems while

the G92 offset is active:

Example 11.6

Changing Work Coordinate Systems With Offset Active

Program

Comment

N1 G10L2P1X0Z0;

Define G54 work coordinate system zero point to be positioned

X0, Z0 away from the machine coordinate system

N2 G10L2P2X20.Z25.;

Define G55 work coordinate system zero point to be positioned

X20, Z25 away from the machine coordinate system

N3 G55X10.Z5.;

Move to X10, Z5 in the G55 work coordinate system

N4 G54X10.Z5.;

Move to X10, Z5 in the G54 work coordinate system

N5 G92X-5.Z-5.;

Offset current wheel position to be at X-5, Z-5

N6 X15.Z0.;

Move to X15, Z0 (offset still active)

N7 G55X10.Z5.;

Move back to X10, Z5 in the G55 work coordinate system with the

G92 offset still active

Figure 11.11

Results of Example 11.6

Zero point for the G54

work coordinate system

N3

Zero point for the G55

work coordinate system

New zero point established

by the G92 block

N6

N7

Final move to X10, Z5

after G92 offset was

activated in previous

work coordinate system

N4

X

X

X

Z

Z

Z

10

20

30

10

20

30

30

30

20

10

12177-I

In Example 11.6, the G92 offset, entered while the G54 work coordinate

system was active, has also shifted the G55 coordinate system. Any offsets

described in this section alter all of the work coordinate systems (G54 -

G59) at the same time.