2 too many non-motion blocks – Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 534

Dresser/Wheel Radius Compensation

Chapter 15

15-46

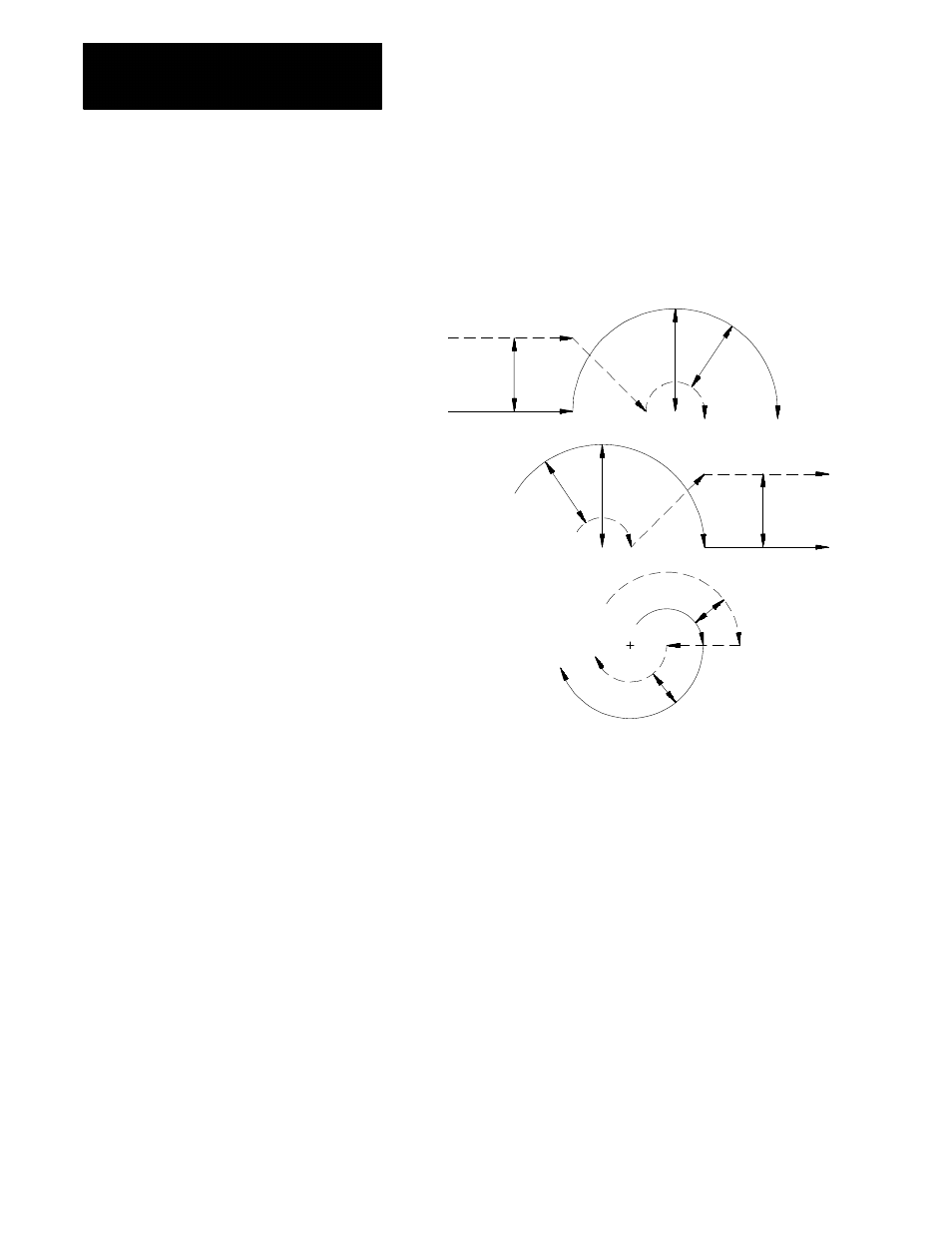

If no intersections of the actual path exist, the compensated path is the

same as if a linear-to-linear intersection had taken place (see Figure 15.39).

Figure 15.39

Change in Compensation With No Possible Path Intersections

Compensated path G41

Programmed path

G42

G42

Programmed path

Compensated path G42

Compensated path G41

Programmed path

r

1

r

2

r

1

r

1

r

1

r

2

r

r

G41

12130-I

The control always looks ahead to the next motion block to determine the

actual path taken for a motion block in radius compensation. If the next

block is not a motion block, the control continues to scan ahead for a

motion block until it either detects one, or the allowable number of

non-motion blocks as set in AMP has been exceeded. See documentation

prepared by your system installer for the allowable number of non-motion

blocks allowed in a specific system.

Important: We define non-motion block as any block within a program

that does not actually generate the movement of one of the axes in the

current compensated plane. Blocks that are skipped by the control because

of the block skip feature (/) described on page 7-2 are also counted as

non-motion blocks in radius compensation regardless of the content of the

skipped block.

15.7.2

Too Many Non-Motion

Blocks