Rockwell Automation 8520-GUM 9/Series CNC Grinder Operation and Programming Manual Documentation Set User Manual

Page 493

Dresser/Wheel Radius Compensation

Chapter 15

15-5

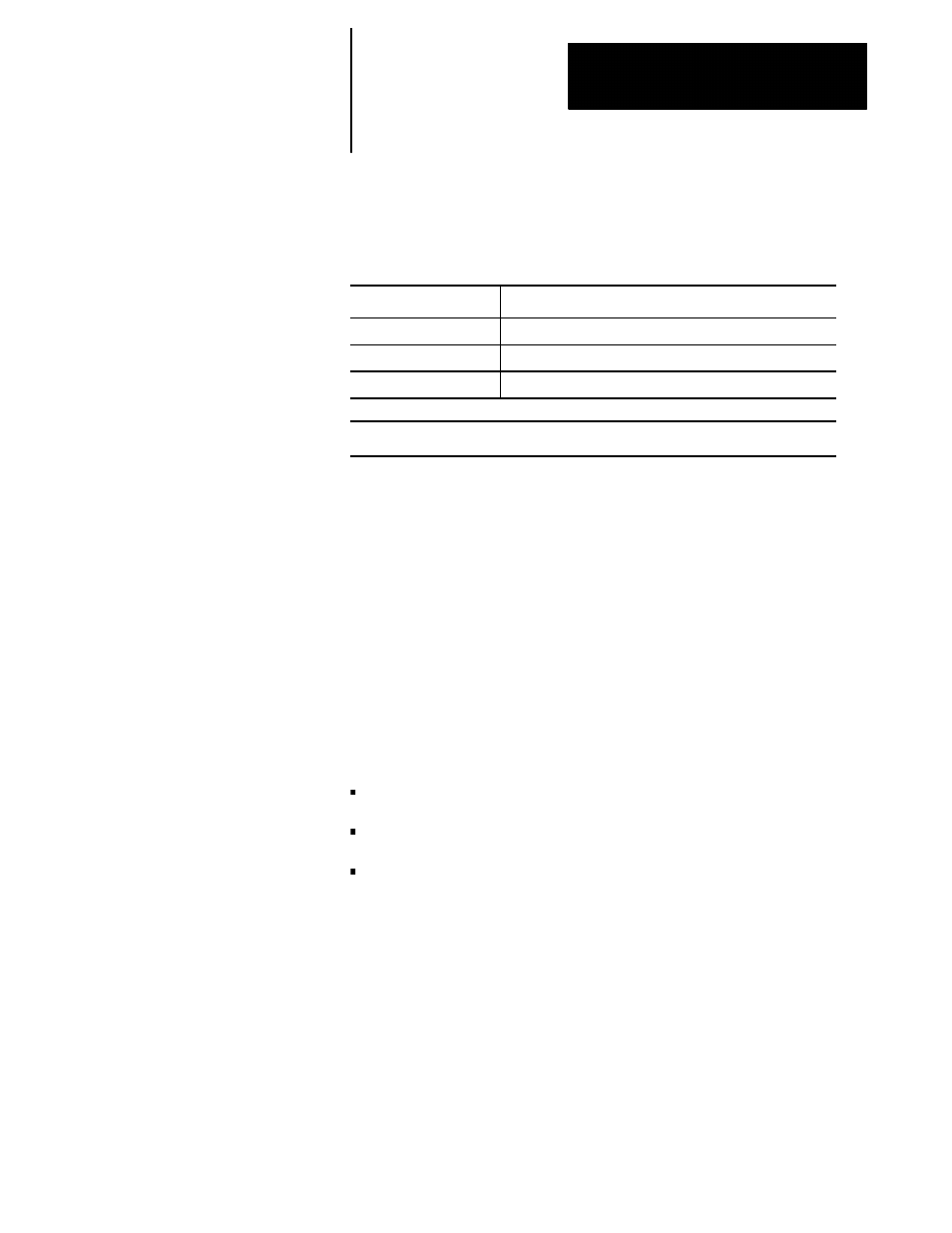

Use the G-codes in Table 15.A for dresser/wheel radius compensation:

Table 15.A

G Code Compensation Direction

G Code

1

:

Dresser/Wheel Radius Compensation:

G40

cancel

G41

left of program path

2

G42

right of program path

2

1

All of these G-codes are modal and belong to the same modal group

2

Left or right is defined as offsetting the dresser/wheel to the left or right of the programmed path

when

facing the direction of axis motion

Important: The dresser/wheel radius compensation function is not

available during thread cutting (G33 and G34). You must cancel

dresser/wheel radius compensation before you perform threading.

Important: If a negative value is set in the offset tables as the

dresser/wheel radius, compensation direction (dresser/wheel left or right) is

reversed for the G41 and G42 codes. You can also reverse G41 and G42

during the mirroring operation. See page 12-79 for details on Mirror

Image operation.

The control supports 3 typical dresser/wheel radius compensation

application schemes. Other schemes can be supported as variations of

these 3 basic applications:

Dresser radius compensation

Corner radius compensation

Entire wheel radius compensation

All of these schemes use the same radius table to store radius values. The

dresser/wheel radius compensation scheme used on your system depends

on the current application of your grinder.

15.2

Programming

Compensation (G40, G41,

G42)

15.2.1

Application Schemes