Melsec-q, Appendices – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 739

Appendix - 97

MELSEC-Q

APPENDICES

Trouble type

Questions/Trouble

Remedy

No.

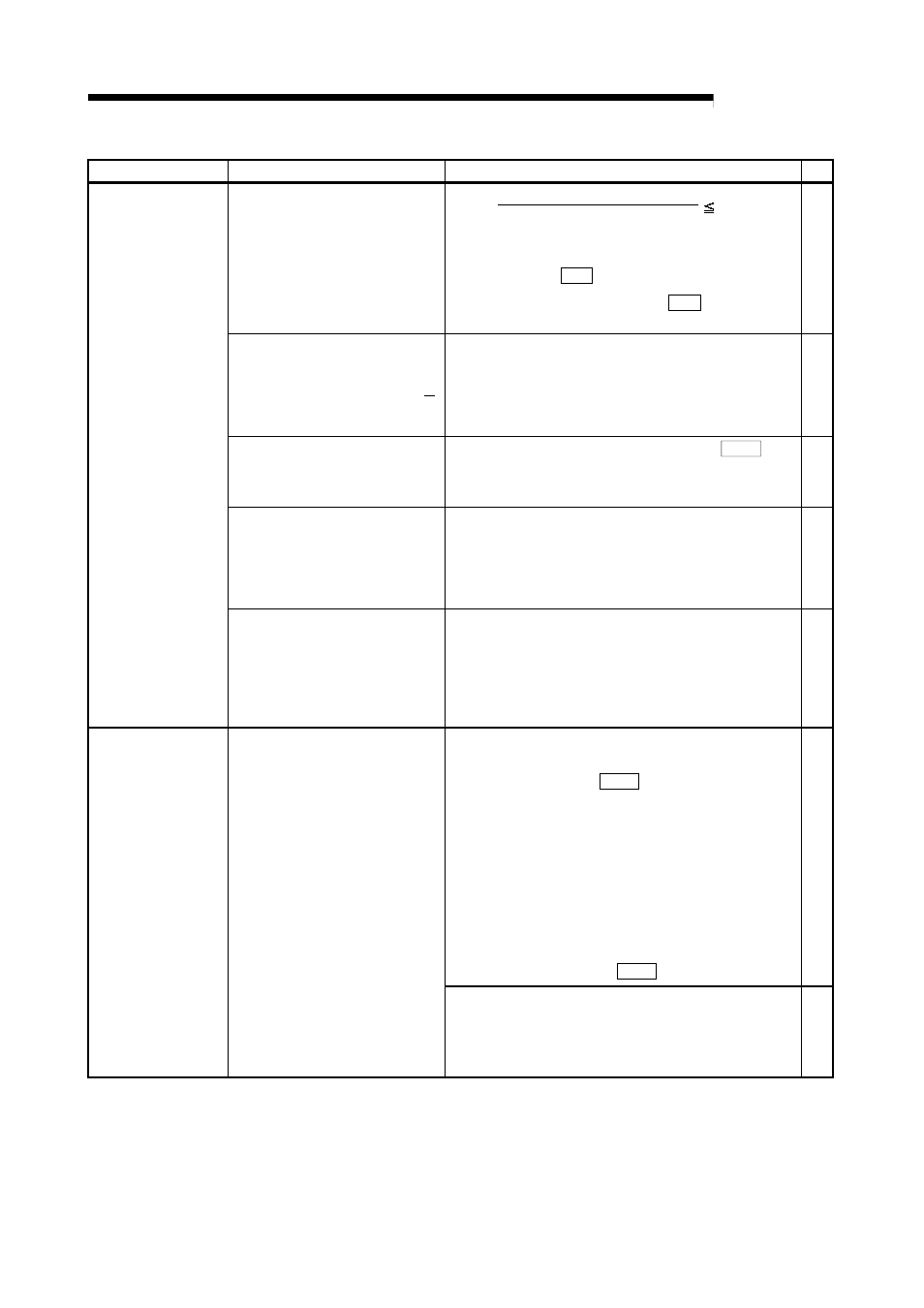

Backlash compensation value

0

≤

Movement amount per pulse

255

Error 920 (backlash compensation

amount error) occurs even when

the backlash compensation value

is set to "1".

Setting is not possible if the above equation is not

satisfied.

Adjust by setting "

Pr.4

Unit magnification" to 10-fold (or

100-fold, or 1000-fold), and setting "

Pr.2

Movement

amount per rotation" to 1/10 (or 1/100, or 1/1000).

48

When a JOG operation is

attempted, errors such as error

104 (hardware stroke limit+) or

error 105 (hardware stroke limit )

occur and the machine does not

move.

The hardware stroke limit wiring has probably not been

carried out.

Refer to Section 12.4.4 "Hardware stroke limit function" for

details, and wire accordingly.

49

Error 997 (Speed selection at OP

shift error) appears when the PLC

READY signal [Y0] turns from OFF

to ON.

A value besides "0" or "1" may be set in the "

Pr.56

Speed designation during OP shift".

Review the set sequence program, and reset the correct

parameters.

50

When the start signal was turned

ON immediately after the stop

signal ON, warning 100 (start

during operation) was detected,

and the start was ignored.

The QD75 starts the deceleration stop process when the

stop signal ON is detected. Thus, the machine interprets

that "positioning is still being executed" immediately after

the stop signal ON. Even if the start signal is turned ON at

that time, the start request will be ignored and warning

100 will occur.

51

Error/warning

Does warning 500 (deceleration

and stop speed change) occur

only during "stop deceleration" and

"automatically deceleration"?

Is there any problem if the

operation is continued in that state

without resetting the error?

The warning occurs only at those times mentioned at the

left. Because this is a warning, there is no problem if the

operation can be continued without resetting the error.

(When the speed is changed using the override, the new

value will not be reflected on the data being executed, but

will be reflected from the next start.)

52

Depending on the stop occurrence factor, positioning may

have not been completed normally.

Check the axis monitor "

Md.26

Axis operation status"

after the BUSY signal has turned OFF.

Stop

: The stop signal has turned ON

during positioning.

Check the condition under which the

stop signal (Y stop, external stop)

turns ON.

Error occurrence

: An error has occurred during

positioning.

Check the error occurrence factor

from "

Md.23

Axis error No.".

53

Positioning complete

signal

Position control was executed but

the positioning complete signal

does not turn ON.

The setting value of the detailed parameter 2 "Positioning

complete signal output time" is 0 or shorter than the scan

time.

Using the sequence program, set the time when the signal

can be detected securely.

54