4 creating start programs for jog operation, Melsec-q – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 450

11 - 10

MELSEC-Q

11 MANUAL CONTROL

11.2.4 Creating start programs for JOG operation

A sequence program must be created to execute a JOG operation. Consider the

"required control data setting", "start conditions" and "start time chart" when creating

the program.

The following shows an example when a JOG operation is started for axis 1.

("

Cd.17

JOG speed" is set to "100.00mm/min" in the example shown.)

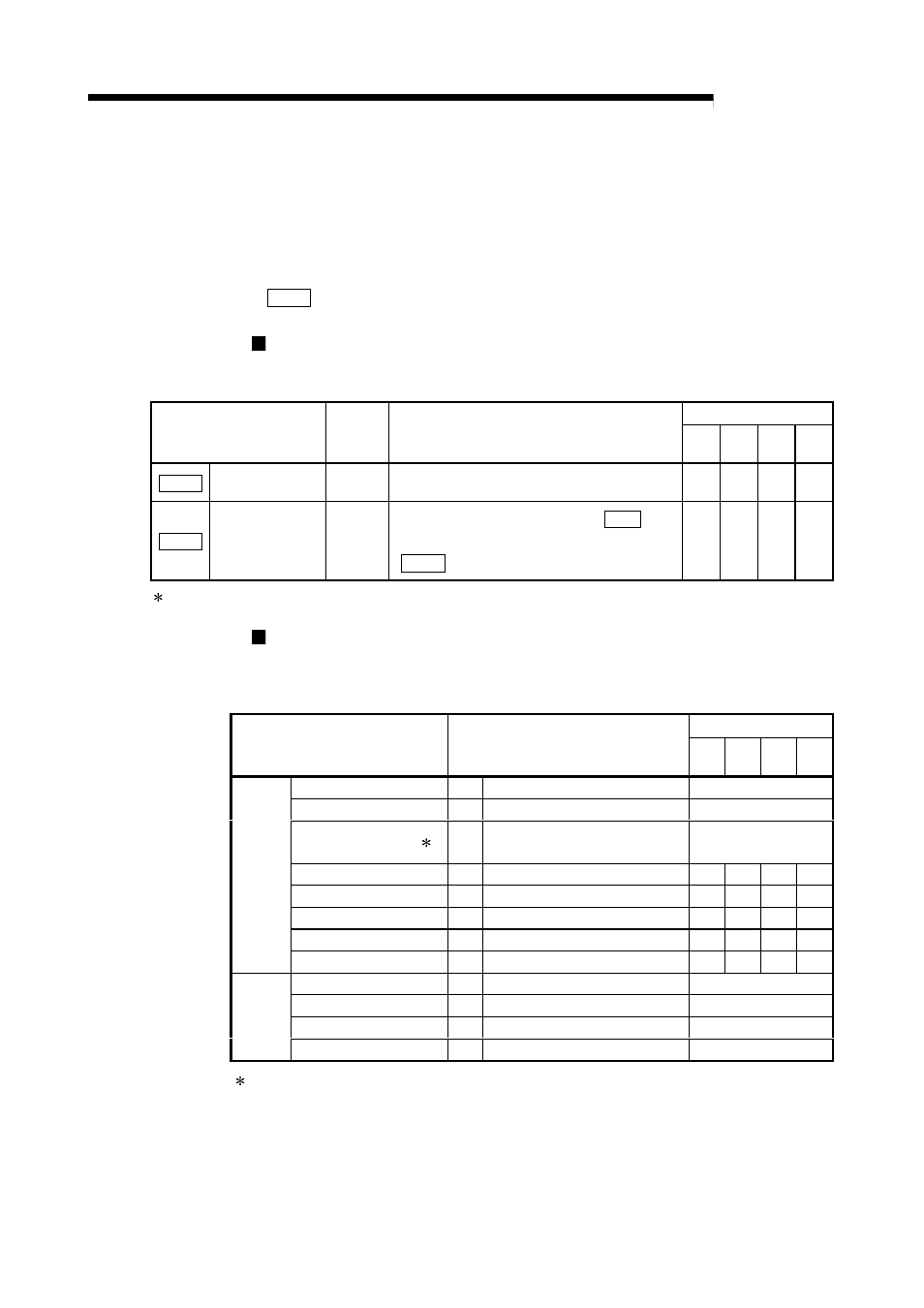

Required control data setting

The control data shown below must be set to execute a JOG operation. The

setting is carried out with the sequence program.

Buffer memory address

Setting item

Setting

value

Setting details

Axis

1

Axis

2

Axis

3

Axis

4

Cd.16

Inching movement

amount

0

Set “0”.

1517 1617 1717 1817

Cd.17

JOG speed

10000

Set a value equal to or above the "

Pr.7

Bias

speed at start" and equal to or below the

" Pr.31 JOG speed limit value".

1518

1519

1618

1619

1718

1719

1818

1819

Refer to Section 5.7 "List of control data" for details on the setting details.

Start conditions

The following conditions must be fulfilled when starting. The required conditions

must also be assembled in the sequence program, and the sequence program

must be configured so the operation will not start if the conditions are not fulfilled.

Device

Signal name

Signal state

Axis

1

Axis

2

Axis

3

Axis

4

PLC READY signal

ON PLC CPU preparation completed

Y0

QD75 READY signal

ON QD75 preparation completed

X0

Synchronization flag

ON

QD75 buffer memory

The access is possible.

X1

Axis stop signal

OFF Axis stop signal is OFF

Y4

Y5

Y6

Y7

Start complete signal

OFF Start complete signal is OFF

X10 X11 X12 X13

BUSY signal

OFF QD75 is not operating

XC

XD

XE

XF

Error detection signal

OFF There is no error

X8

X9

XA

XB

Interface

signal

M code ON signal

OFF M code ON signal is OFF

X4

X5

X6

X7

Drive unit READY signal

ON Drive unit preparation completed

–

Stop signal

OFF Stop signal is OFF

–

Upper limit (FLS)

ON Within limit range

–

External

signal

Lower limit (RLS)

ON Within limit range

–

If the PLC CPU is set to the asynchronous mode in the synchronization setting, this must be

inserted in the program for interlocking. If it is set to the synchronous mode, it must not be

inserted in the program for interlocking because it is turned ON when the PLC CPU executes

calculation.