Melsec-q, Appendices – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 719

Appendix - 77

MELSEC-Q

APPENDICES

FIXED-FEED

This is the feeding of a set dimension for

cutting sheet and bar workpieces into the

designated dimensions. Incremental system

positioning is often used. The current value is

not incremented, even when the feed

operation is repeated.

FLASH MEMORY

This battery-less memory can be used to store

parameters and positioning data for backup.

Because it is battery-less, battery maintenance

is not required

FLAT TYPE MOTOR (PANCAKE MOTOR)

About 100mm shorter in axial dimension than

the standard motor. Used when the

servomotor is installed in a small space.

FLS SIGNAL (forward limit signal)

This is the input signal that notifies the user

that the limit switch (b contact configuration,

normally ON) installed at the upper limit of the

positioning control enabled range has been

activated.

The positioning operation stops when the FLS

signal turns OFF (non-continuity).

G CODE

These are standardized (coded) 2-digit

numerical values (00 to 99) designating

various control functions of the NC module.

Also called G functions.

Example :

G01

Linear interpolation

G02

Circular interpolation CW (clockwise)

G04

Dwell

G28

OPR

G50

Max. spindle speed setting

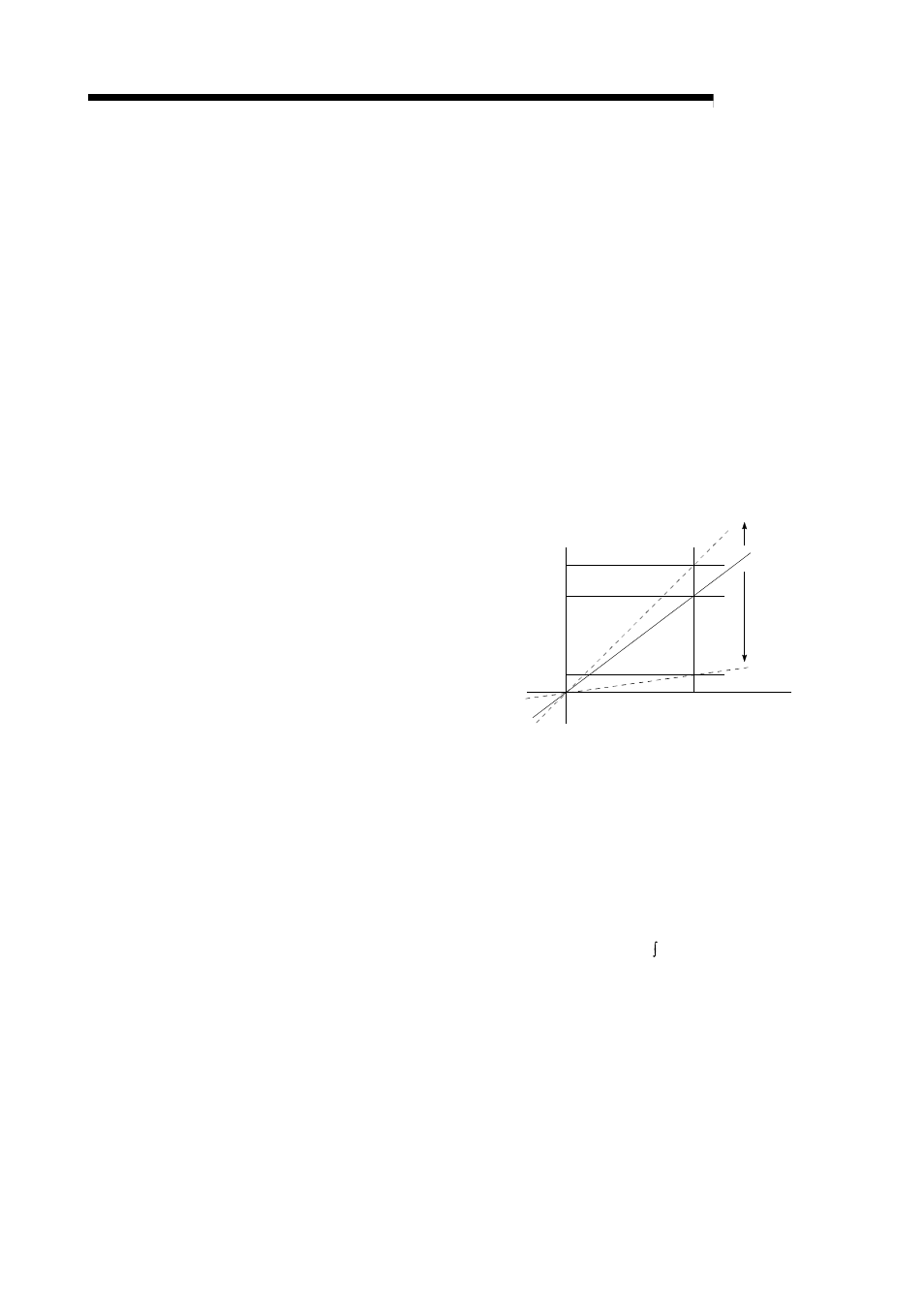

GAIN

The changing of the ratio between two values

having a proportional relation. Seen on a

graph, the changing of the incline of the

characteristics.

13

10

2

10

Raising

the gain

Output

Lowering

the gain

Input

For example, when 10 is output for an input of

10, the output can be changed to 12, 5, etc.,

by changing the gain.

GD

2

The inertia moment. The sum total of the mass

(dm) of each small area configuring an object

multiplied by the square of the distance (r) of

each of those areas from a given straight line.

The relation with I = r

2

dmGD

2

is given by 4gI,

with "g" being gravitational acceleration.