Melsec-q, 14 dedicated instructions [control data, Functions – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 591

14 - 9

MELSEC-Q

14 DEDICATED INSTRUCTIONS

[Control data]

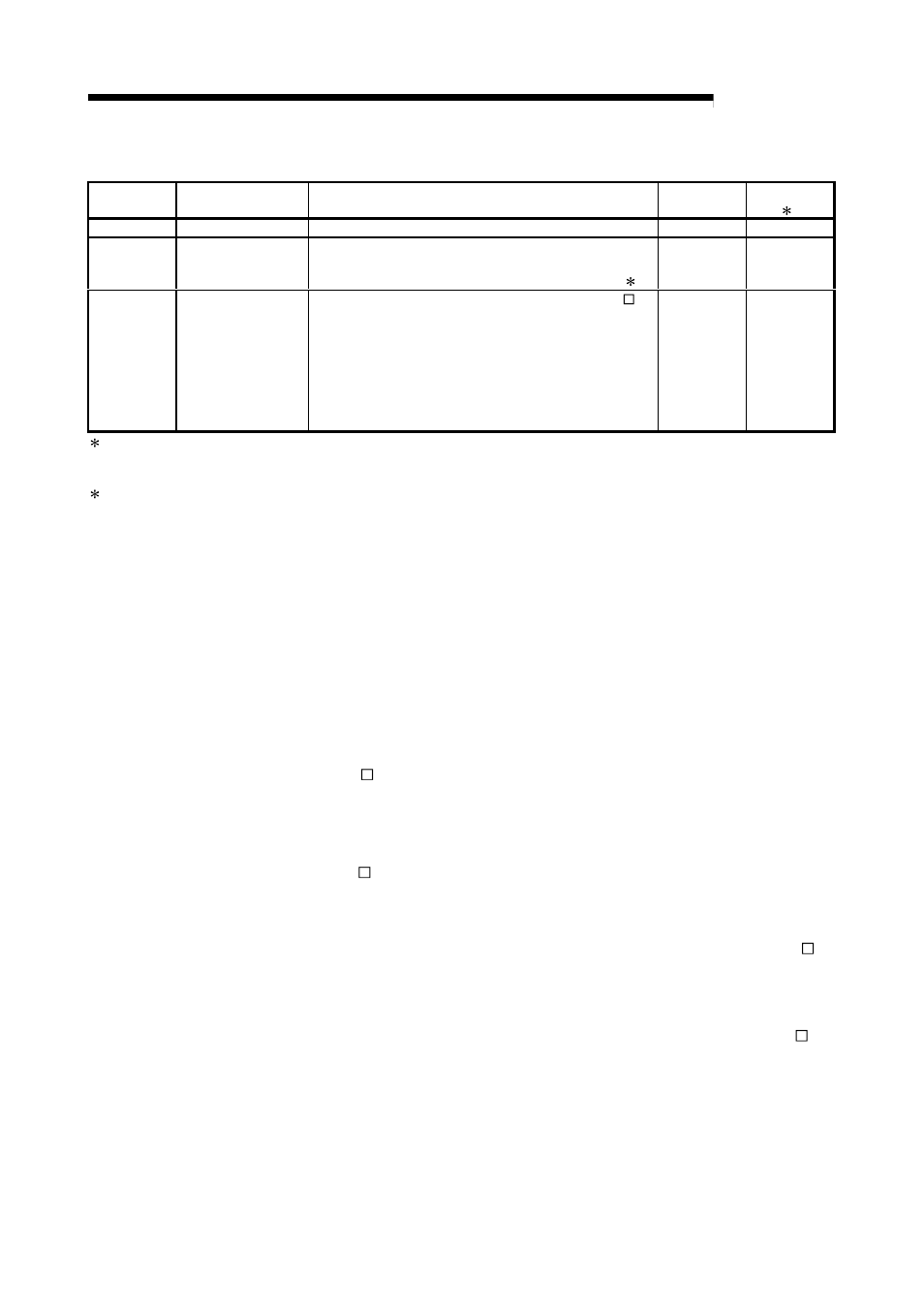

Device

Item

Setting data

Setting range

Setting side

( 1)

(S)+0

System area

–

–

–

(S)+1

Complete status

The state at the time of completion is stored.

• 0

: Normal completion

• Other than 0: Abnormal completion (error code)( 2)

–

System

(S)+2

Start No.

The following data Nos. to be started by the PSTRT

instruction are designated.

• Positioning data No.

: 1 to 600

• Block start

: 7000 to 7004

• Machine OPR

: 9001

• Fast OPR

: 9002

• Current value changing

: 9003

• Multiple axes simultaneous start : 9004

1 to 600

7000 to 7004

9000 to 9004

User

1: The data on the setting side is as follows.

• User

: Data before the execution of dedicated instructions is stored by user.

• System: Data after the execution of dedicated instruction is stored by PLC CPU.

2: Refer to Section 15.2 for error codes at abnormal completion.

[Functions]

(1) The positioning start of the axes to be processed (See below) is carried out.

• PSTRT1: Axis 1

• PSTRT2: Axis 2

• PSTRT3: Axis 3

• PSTRT4: Axis 4

(2) The block start, OPR start, current value changing, and multiple axes

simultaneous start can be carried out by the setting of "start number" 7000 to

7004/9001 to 9004 in ((S)+2).

(3) The PSTRT instruction completion can be confirmed using the complete devices

((D)+0) and ((D)+1).

(a) Complete device ((D)+0)

This device is turned ON by the END processing of the scan for which

PSTRT instruction is completed, and turned OFF by the next END

processing.

(b) Complete state display device ((D)+1)

This device is turned ON and OFF according to the state in which PSTRT

instruction is completed.

• When completed normally

:Kept unchanged at OFF.

• When completed abnormally:This device is turned ON by the END

processing of the scan for which PSTRT

instruction is completed, and turned OFF by

the next END processing. (same ON/OFF

operation as complete device).