Melsec-q, 12 control sub functions – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 549

12 - 73

MELSEC-Q

12 CONTROL SUB FUNCTIONS

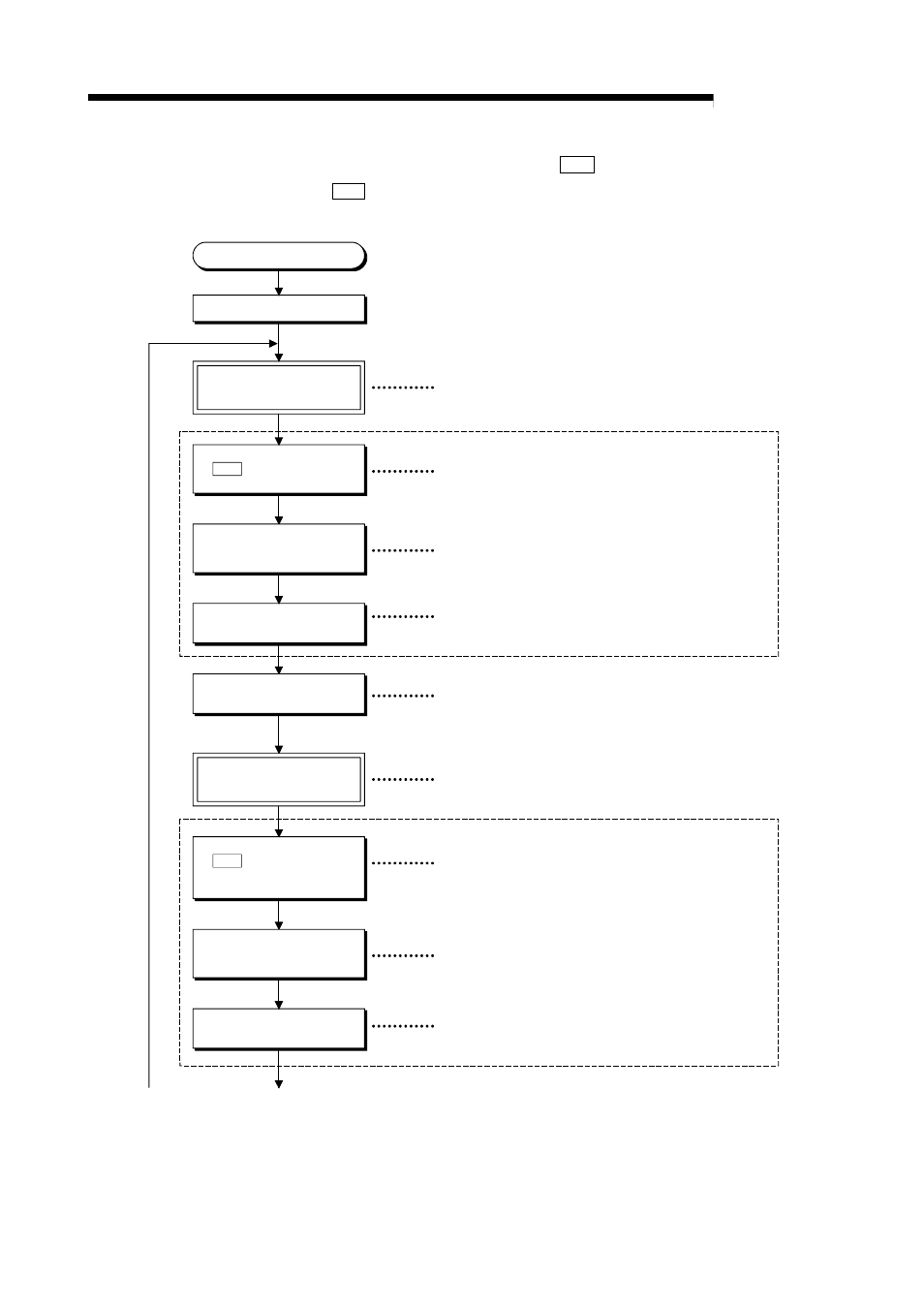

(2) When entering teaching data into "

Da.7

Arc address" and then into

"

Da.6

Positioning address/movement amount" (Teaching example for 2-

axis circular interpolation control with sub point designation on axes 1 and 2)

Start

Carry out a machine OPR.

Move the workpiece to the

circular interpolation sub point

using a manual operation. *1

Set Writes the current feed value

to Da.7 Arc address in teaching

data selection.

Set the positioning data No. for

which the teaching will be carried

out.

Using a JOG operation, inching operation, or manual pulse generator.

Set 1 in the buffer memory address [1548].

Set the positioning data No. in buffer memory address [1549].

Confirm completion of the

teaching.

Confirm 0 in buffer memory address [1549].

Teach arc sub point address of

axis 2.

Entering teaching data to buffer memory address [1648] and [1649],

in the same fashion as for axis 1.

Move the workpiece to the

circular interpolation end point

using a manual operation. *2

Using a JOG operation, inching operation, or manual pulse generator.

Set Writes the current feed value

to Da.6 Positioning address/

movement amount by teaching

data selection.

Set 0 in buffer memory address [1548].

Set the positioning data No. for

which the teaching will be carried

out.

Set the positioning data No. in buffer memory address [1549].

Confirm completion of the

teaching.

Confirm 0 in buffer memory address [1549].

Teaching arc sub point address on axis 1

Teaching arc end point address on axis 1

2)

1)