Melsec-q, 5 data used for positioning control [table 1 – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 145

5 - 57

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

[Table 1]

Pr.1

setting value

Value set with peripheral device

(unit)

Value set with sequence program

(unit)

0 : mm

-214748364.8 to 214748364.7 (

µ

m)

-2147483648 to 2147483647 (

×

10

-1

µ

m)

1 : inch

-21474.83648 to 21474.83647 (inch)

-2147483648 to 2147483647 (

×

10

-5

inch)

2 : degree

-21474.83648 to 21474.83647 (degree)

-2147483648 to 2147483647 (

×

10

-5

degree)

3 : pulse

-2147483648 to 2147483647 (pulse)

-2147483648 to 2147483647 (pulse)

Pr.54 OPR torque limit value

Set the value to limit the servomotor torque after reaching the creep speed during

machine OPR.

Refer to Section 12.4.2 "Torque limit function" for details on the torque limits.

Pr.55 Deviation counter clear signal output time

Set the duration of the deviation counter clear signal output during a machine OPR

operation using any of the following methods: the near-point dog method, stopper

methods 1) to 3), and count method 1). (For details, refer to your drive unit

manual.)

Pr.56 Speed designation during OP shift

Set the operation speed for when a value other than "0" is set for "

Pr.53

OP shift

amount". Select the setting from "

Pr.46

OPR speed" or "

Pr.47

Creep speed".

0 : Designate "

Pr.46

OPR speed" as the setting value.

1 : Designate "

Pr.47

Creep speed" as the setting value.

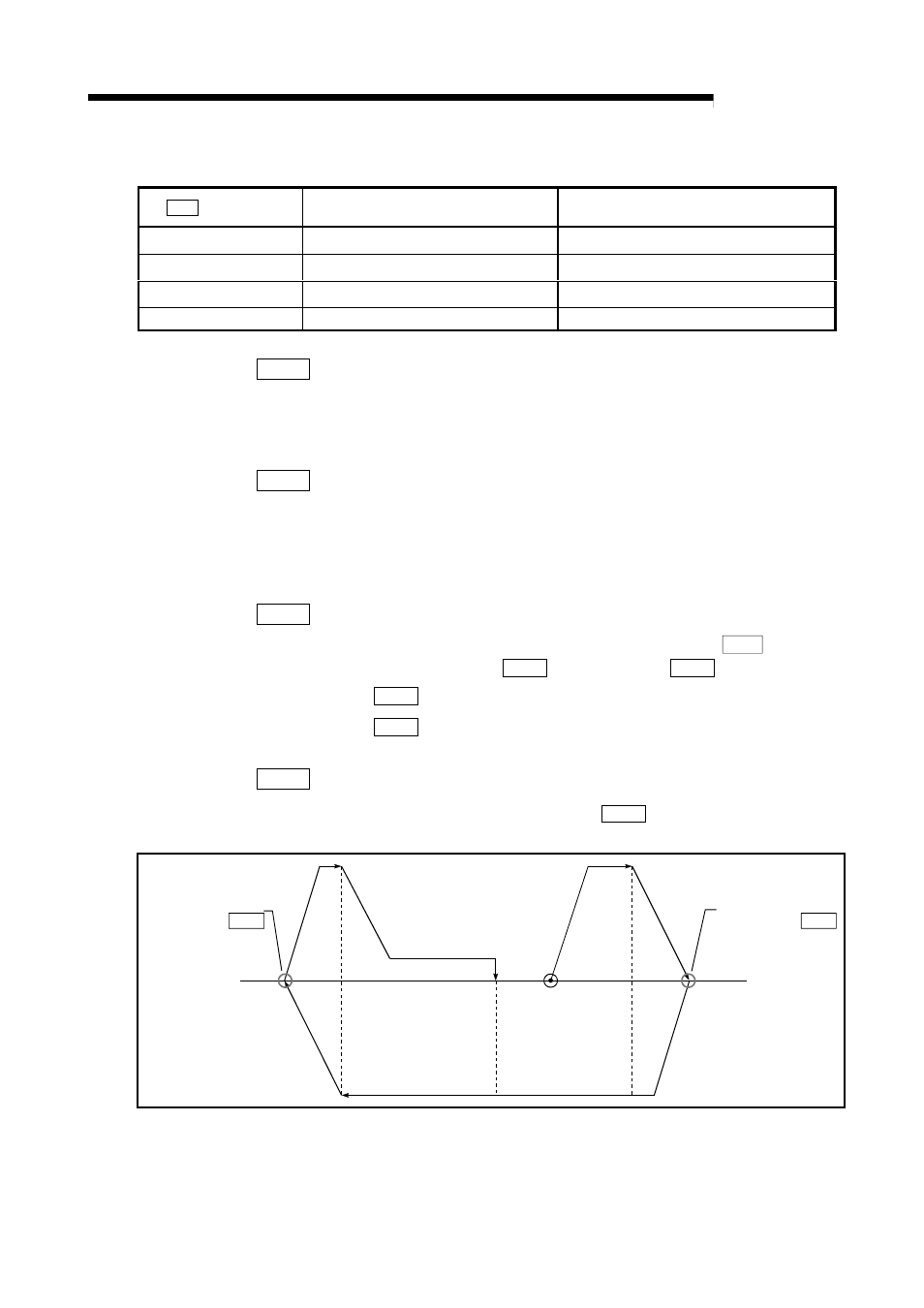

Pr.57 Dwell time during OPR retry

When OPR retry is validated (when "1" is set for

Pr.48

), set the stop time after

decelerating in 2) and 4) in the following drawing.

Start position

Temporarily stop for

the time set in Pr. 57

Temporarily stop for

the time set in Pr. 57

1)

2)

3)

4)

5)

6)