3 opr method (1): near-point dog method, Melsec-q, Operation chart – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 284: Fig. 8.2 near-point dog method machine opr

8 - 6

MELSEC-Q

8 OPR CONTROL

8.2.3 OPR method (1): Near-point dog method

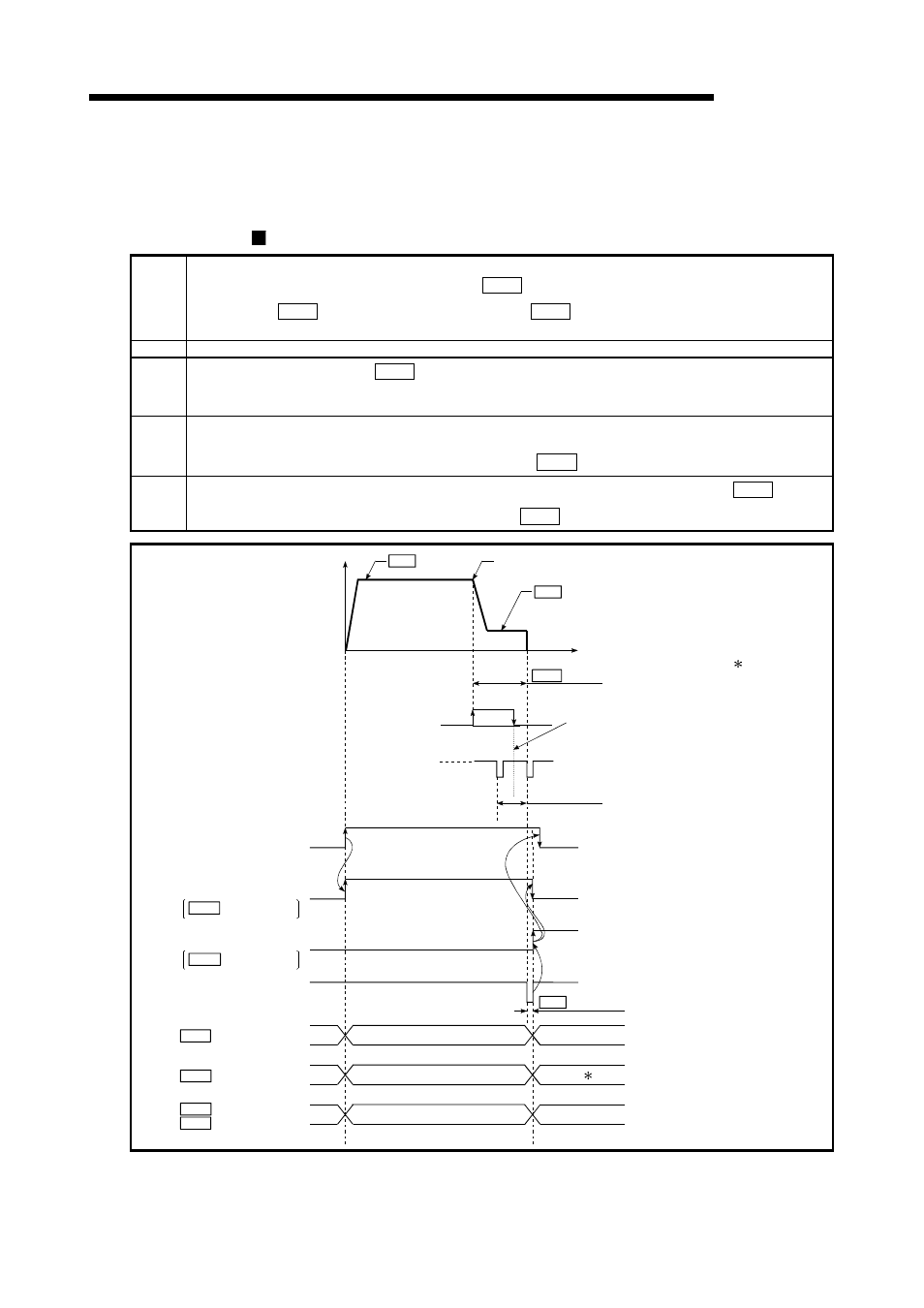

The following shows an operation outline of the "near-point dog method" OPR method.

Operation chart

1)

The machine OPR is started.

(The machine begins the acceleration designated in "

Pr.51

OPR acceleration time selection", in the direction

designated in "

Pr.44

OPR direction". It then moves at the "

Pr.46

OPR speed" when the acceleration is

completed.)

2)

The machine begins decelerating when the near-point dog ON is detected.

3)

The machine decelerates to the "

Pr.47

Creep speed", and subsequently moves at that speed.

(At this time, the near-point dog must be ON. The workpiece will continue decelerating and stop if the near-point dog is

OFF.)

4)

After the near-point dog turns OFF, the pulse output from the QD75 will stop at the first zero signal,

outputting a "deviation counter clear signal" to the drive unit.

(The "deviation counter clear signal output time" is set in

Pr.55

.)

5)

After a "deviation counter clear signal" is output to the drive unit, the OPR complete flag (

Md.31

Status:

b4) turns from OFF to ON and the OPR request flag (

Md.31

Status: b3) turns from ON to OFF.

t

Machine OPR start

(Positioning start signal)

ON

OFF

OPR speed

Deceleration at the near-point dog ON

Creep speed

ON

OFF

OFF

ON

Standing by

In OPR

Standing by

Axis operation status

Inconsistent

0

Movement amount after

near-point dog ON

Value of the machine moved is stored.

OP address

Current feed value

Machine feed value

V

Zero signal

Value of 1

Deviation counter clear output

Movement amount after near-point dog ON

Near-point dog

ON

OFF

One servomotor rotation

1

OPR request flag

OPR complete flag

Md.34

Adjust so the near-point dog OFF position is

as close as possible to the center of the zero

signal HIGH level.

If the near-point dog OFF position overlaps with

the zero signal, the machine OPR stop position

may deviate by one servomotor rotation.

1)

2)

3)

4) 5)

Pr.46

Pr.47

Md.34

Md.20

Md.21

Md.26

Md.31

Md.31

Deviation counter clear

signal output time

Pr.55

Status: b3

Status: b4

Inconsistent

Fig. 8.2 Near-point dog method machine OPR