Melsec-q, 3] setting the torque change function start signal – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 525

12 - 49

MELSEC-Q

12 CONTROL SUB FUNCTIONS

[2] Precautions during control

(1) If a value besides "0" is set in the "

Cd.22

New torque value", the torque

generated by the servomotor will be limited by that value. To limit the torque

with the value set in "

Pr.17

Torque limit setting value", set the "

Cd.22

New torque value" to "0".

(2) The "

Cd.22

New torque value" is validated when written to the QD75.

(Note that it is not validated from the time the power supply is turned ON to

the time the PLC READY signal (Y0) is turned ON.)

(3) If the setting value is outside the setting range, an axis warning "Outside

new torque value range" (warning code: 113) will occur and the torque will

not be changed.

(4) If the time to hold the new torque value is not more than 100ms, a torque

change may not be executed.

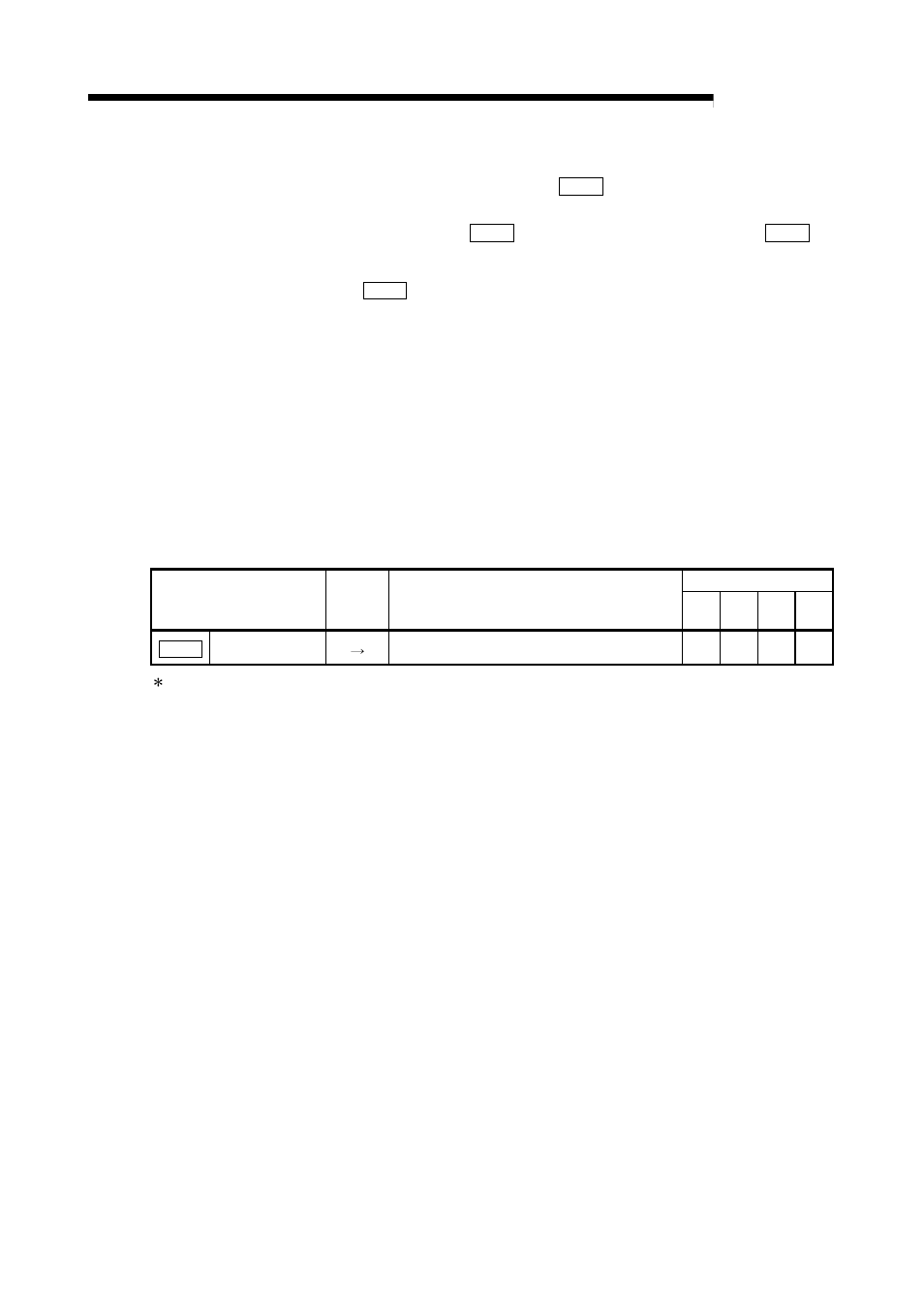

[3] Setting the torque change function start signal

To use the "torque change function", write the data shown in the following table

to the QD75 using the sequence program.

The set details are validated when written to the QD75.

Buffer memory address

Setting item

Setting

value

Setting details

Axis

1

Axis

2

Axis

3

Axis

4

Cd.22

New torque value

Set the new torque limit value.

1525 1625 1725 1825

Refer to Section 5.7 "List of control data" for details on the setting details.