Melsec-q, 15 troubleshooting – MITSUBISHI ELECTRIC Mitsubishi Programmable Logic Controller QD75D User Manual

Page 619

15 - 15

MELSEC-Q

15 TROUBLESHOOTING

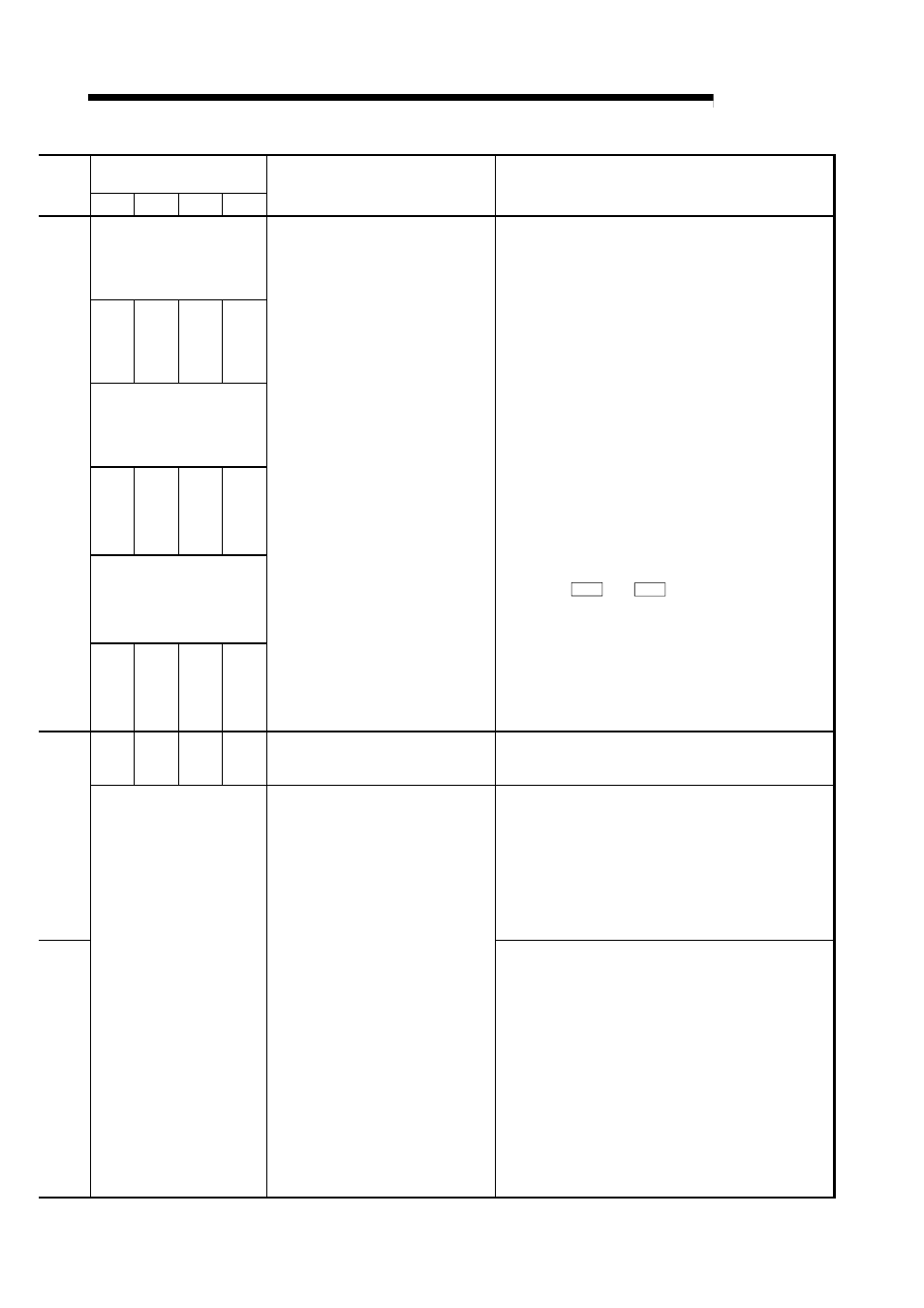

Related buffer memory

address

Axis 1 Axis 2 Axis 3 Axis 4

Set range

(Setting with sequence program)

Remedy

New current value

1506

1507

1606

1607

1706

1707

1806

1807

Software stroke limit

upper limit

18

19

168

169

318

319

468

469

Software stroke limit

lower limit

20

21

170

171

320

321

470

471

limits> • [mm] [inch] [pulse] –2147483648 to 2147483647 • [degree] 0 to 35999999 At start: Bring the current feed value into the software stroke limit using the manual control New current value: Bring the new current value into the software During operation: Correct the positioning address. Da.6 and Da.7 in Section 5.3.) 1506 1606 1706 1806 [degree] 0 to 35999999 Bring the new current value into the setting range. • Do not designate a current value changing using the positioning data following the continuous path control. • Do not designate a "current value changing" using the positioning data following the continuous path control. Refer to Section 5.3 "List of positioning data" 01 H to 1E H , 80 H to 84 H • 03 H , 0C H , 17 H , 1C H : 1 to 4 axis fixed-feed control • 04 H , 05 H , 13 H , 14 H , 18 H , 19 H , 1D H , 1E H : 1 to 4 axis speed control • 81 H : current value changing • Speed-position switching control: 06 H , 07 H • Position-speed switching control: 08 H , 09 H • 01: Continuous positioning control • 11: Continuous path control • Do not designate a speed control, fixed-feed, speed- position switching control, and position-speed • Do not carry out the fixed-feed, speed control, speed- position switching control, and position-speed • Do not carry out the speed control and position-speed switching control using the continuous path control

operation.

(Refer to Chapter 11)

Correct the positioning address (Also check

the arc address in circular interpolation with

sub points designated).

stroke limit. (Refer to Section 9.2.19)

(For the positioning and arc addresses, refer

to

1507

1607

1707

1807

(Refer to Section 9.2.19)

(Refer to Section 9.2.19)

switching control using the positioning data following

the continuous path control data.

switching control using the continuous path control

operation pattern.

operation pattern.

(Refer to Chapter 9)