Rockwell Automation 5370-CVIM2 Module User Manual

Page 422

Chapter 7

Inspection Tools

7–184

The

Conditions

panel also contains two checkboxes and two buttons, which

are described briefly, as follows:

•

Enable –– The

Enable

checkbox is used to enable or disable the

corresponding inspection tool. The tool is enabled when a check mark (

√)

appears in the checkbox, and is disabled when the box is empty. The

selection can be changed to its opposite state by picking the box

alternately.

•

Invert –– The

Invert

checkbox is used to enable or disable the invert

function for the selected condition (input or tool result). The invert

function is enabled when a check mark (

√) appears in the checkbox, and

is disabled when the box is empty. The function can be changed to its

opposite state by picking the box alternately.

When the invert function is enabled, the “condition” will be satisfied

when its opposite state is asserted; thus, if

Tool 1

–

Pass

is the selected

condition, as shown in Figure 7.147 (page 7–183), and

Invert

is enabled,

the condition will be satisfied when the opposite state (that is,

Fail

) is

present. Similarly, if input

In1

is the selected condition and

Invert

is

enabled, the condition is satisfied when

In1

is inactive. Further, if

Zero

is

the selected condition with

Invert

enabled, the condition is satisfied when

a non–zero condition occurs.

•

Done –– Use the

button to save the highlighted condition and exit

the

Conditions

panel.

•

Cancel –– Use the

button to exit the

Conditions

panel without

saving any newly selected conditions.

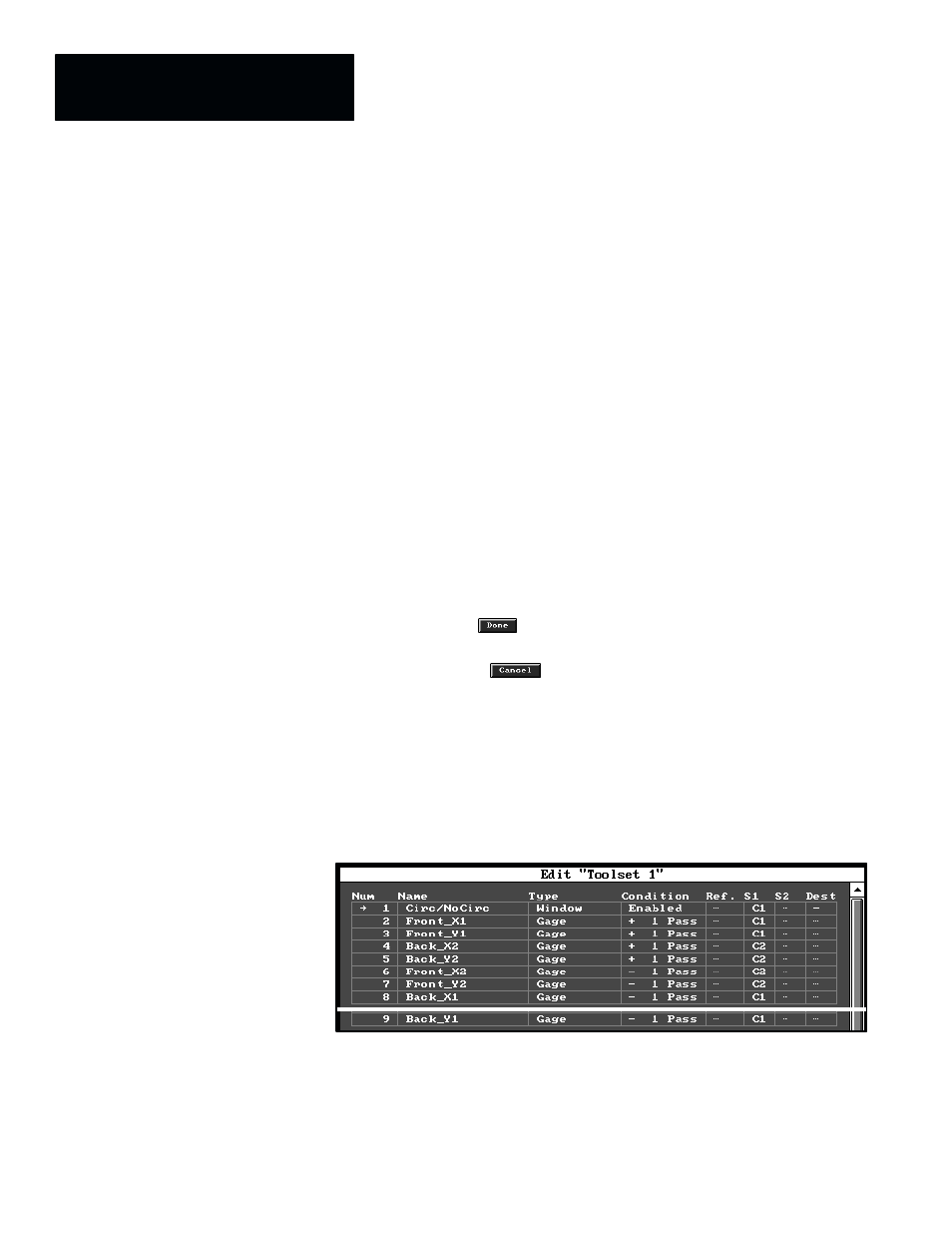

Figure 7.148 and Figure 7.149 provide an example inspection that illustrates

the concept of conditional processing. Figure 7.148 shows a toolset edit

panel containing one window tool and eight gage tools. The window tool and

four of the gage tools receive their image from

C1

(camera #1), while the

other four gage tools receive their image from

C2

(camera #2).

Figure 7.148 Tool Setup For Conditional Processing Example

(Note that a toolset edit panel can display only eight tools at one time; thus,

the ninth tool in this example is shown separately, below the first eight tools.)