Rockwell Automation 5370-CVIM2 Module User Manual

Page 206

5

Chapter

Chapter 6

Reference Tools

6–47

Note that the

Second Pass

panel is a scaled down version of the

First Pass

panel. It has only the

Masking

and

Stop When

selection fields and the

“

Ignore

” and “

Max. RMS

” pixel error parameter entry fields. X and Y

scaling is fixed at the 1:1 ratio. The same defaults are used. For information

about these parameters, refer to the First Pass Configuration section.

When

Double Pass

is enabled (default), the second pass operates on the

results created by the first pass operation. The principal advantage of using

two passes is the achievement of high resolution in coordinate and angle

results without the significant speed penalty that usually occurs when using

one pass with high resolution scaling (1:1) for X and Y axis scaling.

During the second pass, the feature window searches only in the part of the

search window in which the first pass located a feature –– it does not search

the whole search window –– thereby saving considerable time in many cases.

Table 6.2 demonstrates the speed difference for one feature (A or B) using

the same feature image and search image for single pass and double pass.

These results are derived from an actual setup in which the “pick and place”

coordinates of the feature image were 120 and 143 for the X–axis and

Y–axis, respectively.

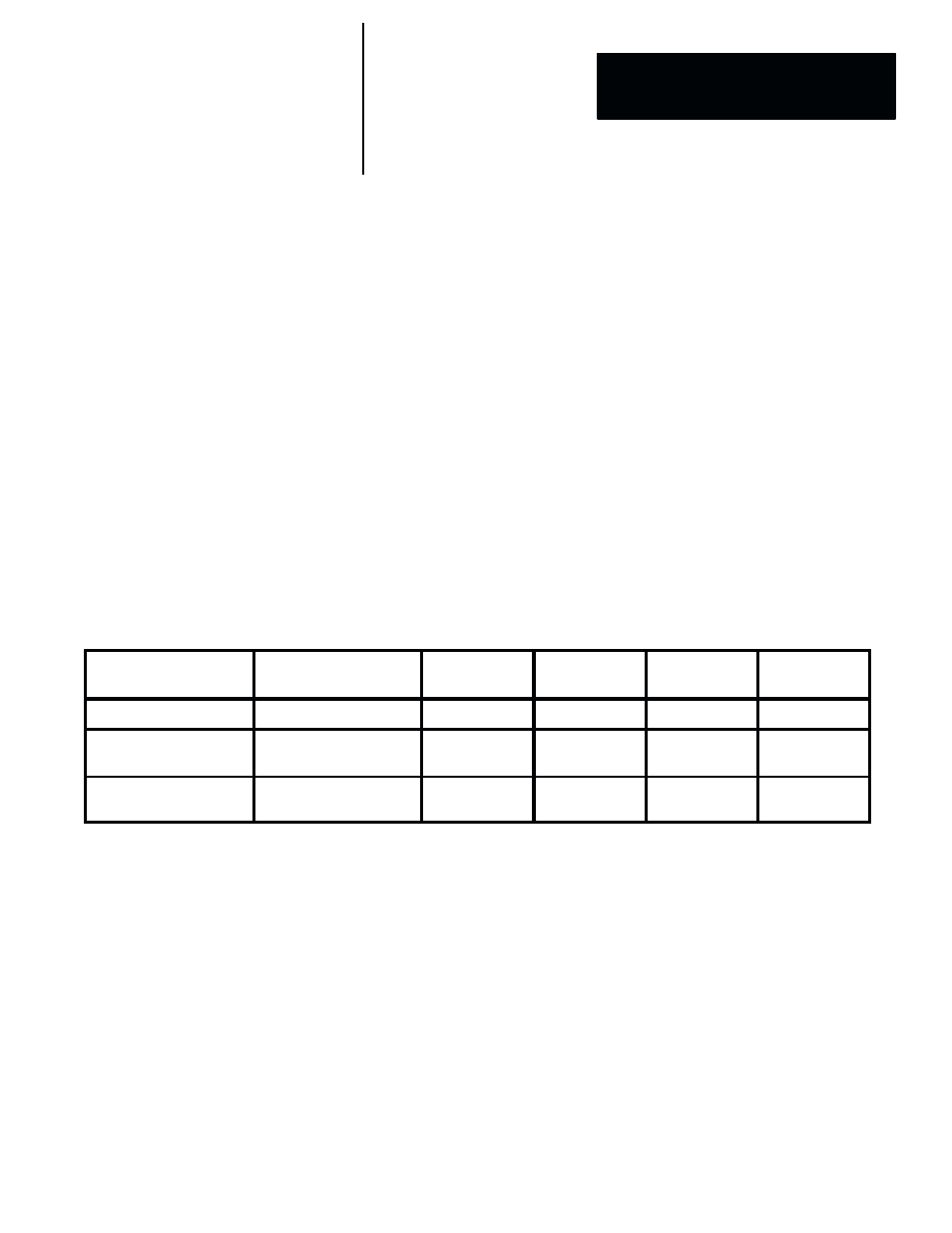

Table 6.2 Example: Comparison of Single Pass and Double Pass Performance

Operation

Scaling

Masking

Coordinates

(X, Y)

Time for

“Best”

Time for

“First”

Single Pass

1:1 for X and Y axes

Enabled

120, 143

1980ms

350ms

Double Pass:

First Pass

1:8 for X and Y axes

Enabled

119, 139

Not used

10ms

Double Pass:

Second Pass

1:1 for X and Y axes

(not user selectable)

Enabled

120, 143

28ms

Not used

Note that when using single pass with high resolution scaling (1:1 for X and

Y axes), the coordinates were located at 120 and 143, the original locations,

but the processing times were quite long: 350ms for “First,” and 1980ms

(almost two seconds) for “Best.”

However, when using a double pass with low resolution scaling (1:8 for X–

and Y–axes), the first pass requires only 10ms to locate the feature

approximately, and the second pass requires only an additional 28ms to

locate the feature more precisely. Note that in this example the coordinates of

the located feature are the same as in the original feature image: 120 and

143. The total time is 38ms for the double pass operation vs at least 350ms

for the single pass operation.

NOTE: If you are using a reference window for rotation compensation,

return to page 6–30 and repeat the configuration process for Feature B.