Conditional processing – Rockwell Automation 5370-CVIM2 Module User Manual

Page 421

5

Chapter

Chapter 7

Inspection Tools

7–183

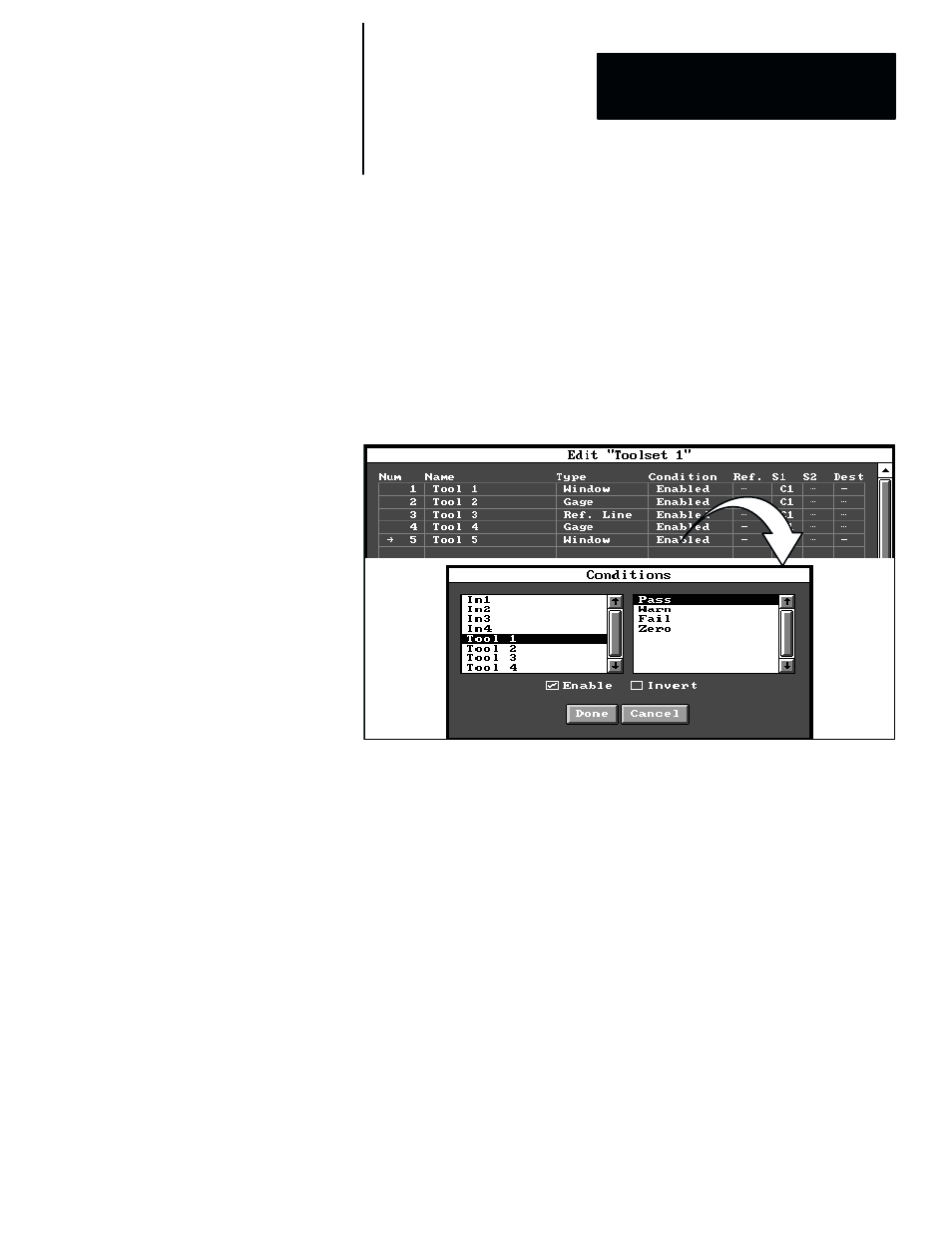

This section discusses “conditional processing,” which, when selected for a

specific inspection tool, permits that tool to execute only when a specific

“condition” (such as an active input signal, or a “pass” tool result) is

satisfied. The main effect of conditional processing is this: When the

specified condition is satisfied, the tool executes; when the condition is not

satisfied, the tool does not execute.

Conditions are selected from the

Conditions

panel, which can be accessed

from the toolset edit panel by picking the

Condition

field for a specific tool,

as illustrated by the example in Figure 7.147.

Figure 7.147 Example: Accessing Conditions Panel

ЗЗЗЗЗЗ

ЗЗЗЗЗЗ

ЗЗЗЗЗЗ

ЗЗЗЗЗЗ

The

Conditions

panel in Figure 7.147 illustrates the basic condition

selections, which are described briefly, as follows:

•

In1 – In4 –– The status of these inputs (that is, logic “0” or logic “1”) can

be used to determine whether or not the corresponding “conditional” tool

will execute. (Note that when any of these inputs are selected for

conditional use, they must also be defined in the Discrete I/O panel. Refer

to the In1 – In4 Input Selection section, on page 9–6 of Chapter 9, for

more information.)

•

Tool n –– This indicates the name of a specific tool, whose status

determines whether or not the corresponding “conditional” tool will

execute. (The

Tool n

selections must always include a selection from the

second list.)

•

Pass, Warn, Fail, Zero –– These selections specify the status of

Tool n

that will determine whether or not the corresponding “conditional” tool

executes. (Note that the “Zero” selection is not available for all tools; for

example, the reference line tool and the image tool.)

Conditional Processing