Rockwell Automation 5370-CVIM2 Module User Manual

Page 344

Chapter 7

Inspection Tools

7–106

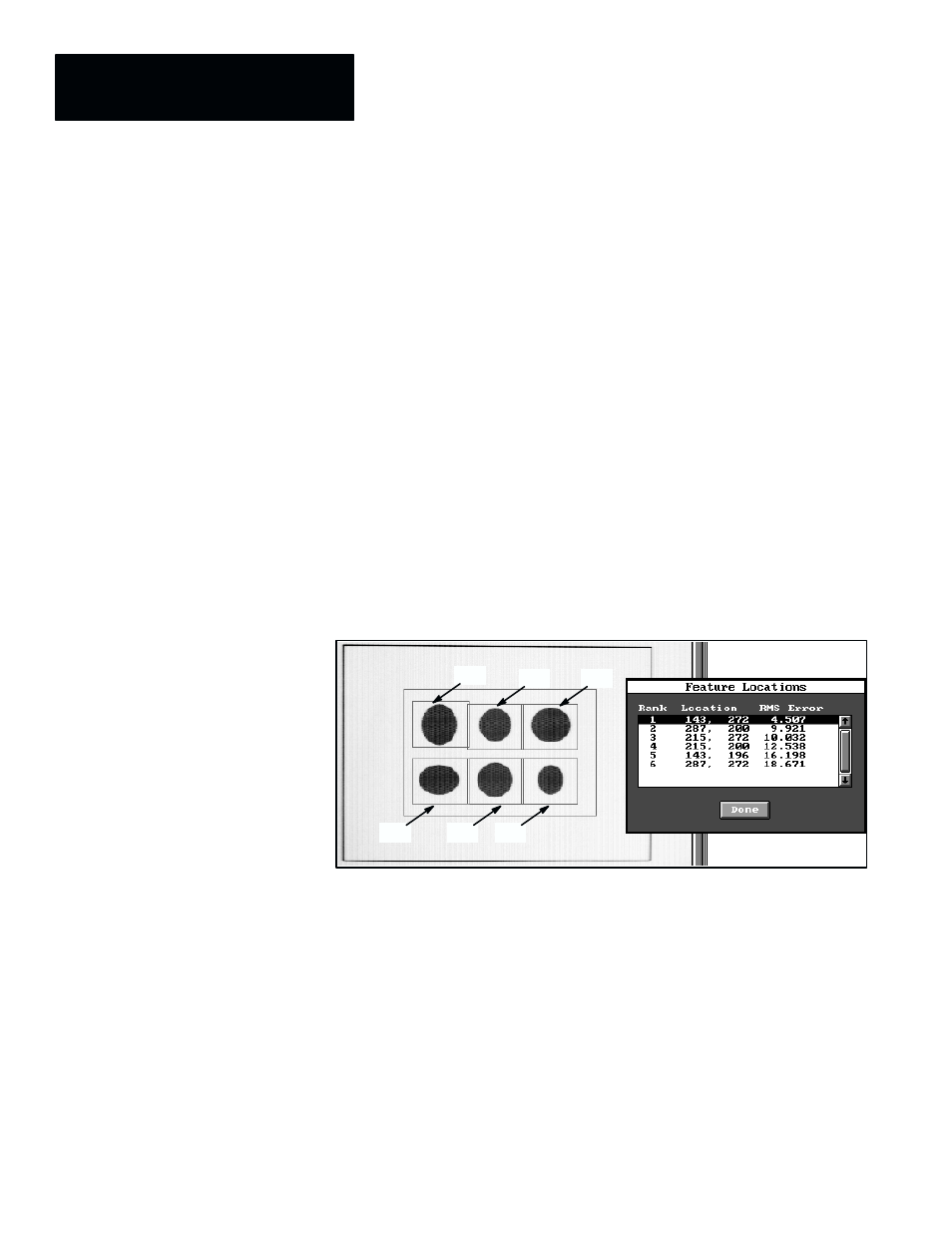

The data in the

Feature Locations

panel appears under three columns,

which are defined as follows:

•

Rank –– This identifies the features in the list in ascending order of their

RMS values. (The currently highlighted item in the panel corresponds to

the green feature window in the image.)

•

Location –– This identifies the X– and Y–axis coordinates of the

upper–left corner of each feature window.

•

RMS Error –– This displays the calculated RMS (root mean square)

error for each feature (refer to the Pixel Error Parameter Selections

section on page 6–43 for details about RMS error calculations).

Note that rank 1 in the

Feature Locations

panel is highlighted. The

corresponding feature window, labeled #1 in the figure, appears in green. All

the other feature windows appear in red. If ranks 2 through 6 are highlighted,

one at a time, the corresponding feature windows will appear in green in the

numerical order shown in the figure.

Figure 7.88 illustrates the appearance of the

Feature Locations

panel and

the windows when using the “

Stop When Best

” parameter.

Figure 7.88 Example: Feature Locations Panel (“Stop When Best Feature” Enabled)

#1

#2

#4

#3

#5

#6

Note the slight differences in the coordinate and RMS values in the panel,

and in the numerical order of the feature windows in the image. These

differences arise because the “stop when best” parameter forces the feature

window to scan the entire search window and record the best match at each

object location.

The “stop when first” parameter, however, causes the feature window to be

satisfied when it matches the designated number of objects that match. The

first match may or may not also be the best match in every case. For

example, object #4 in the “stop when first” evaluation (X and Y = 215 and

268; RMS = 13.773) becomes object #3 (X and Y = 215 and 272; RMS =

10.032) in the “stop when best” evaluation.