X only – Rockwell Automation 5370-CVIM2 Module User Manual

Page 163

Chapter 6

Reference Tools

6–4

The sections following Table 6.1 provide detailed descriptions of the six

reference line tool operations and how they apply shift and/or rotation

compensation to the associated inspection tool during setup and online

operations.

Table 6.1 Reference Line Operations: Summary

Reference Line

Operation

Functions

X only

Compensates for horizontal (X–axis) shift only.

Y only

Compensates for vertical (Y–axis) shift only.

X then Y

Compensates for horizontal (X–axis) shift first, then vertical (Y–axis) shift.

Y then X

Compensates for vertical (Y–axis) shift first, then horizontal (X–axis) shift.

X’, X then Y

Compensates for horizontal (X–axis) shift and rotation (two X axes) first, then

vertical (Y–axis) shift.

Y’, Y then X

Compensates for vertical (Y–axis) shift and rotation (two Y axes) first, then

horizontal (X–axis) shift.

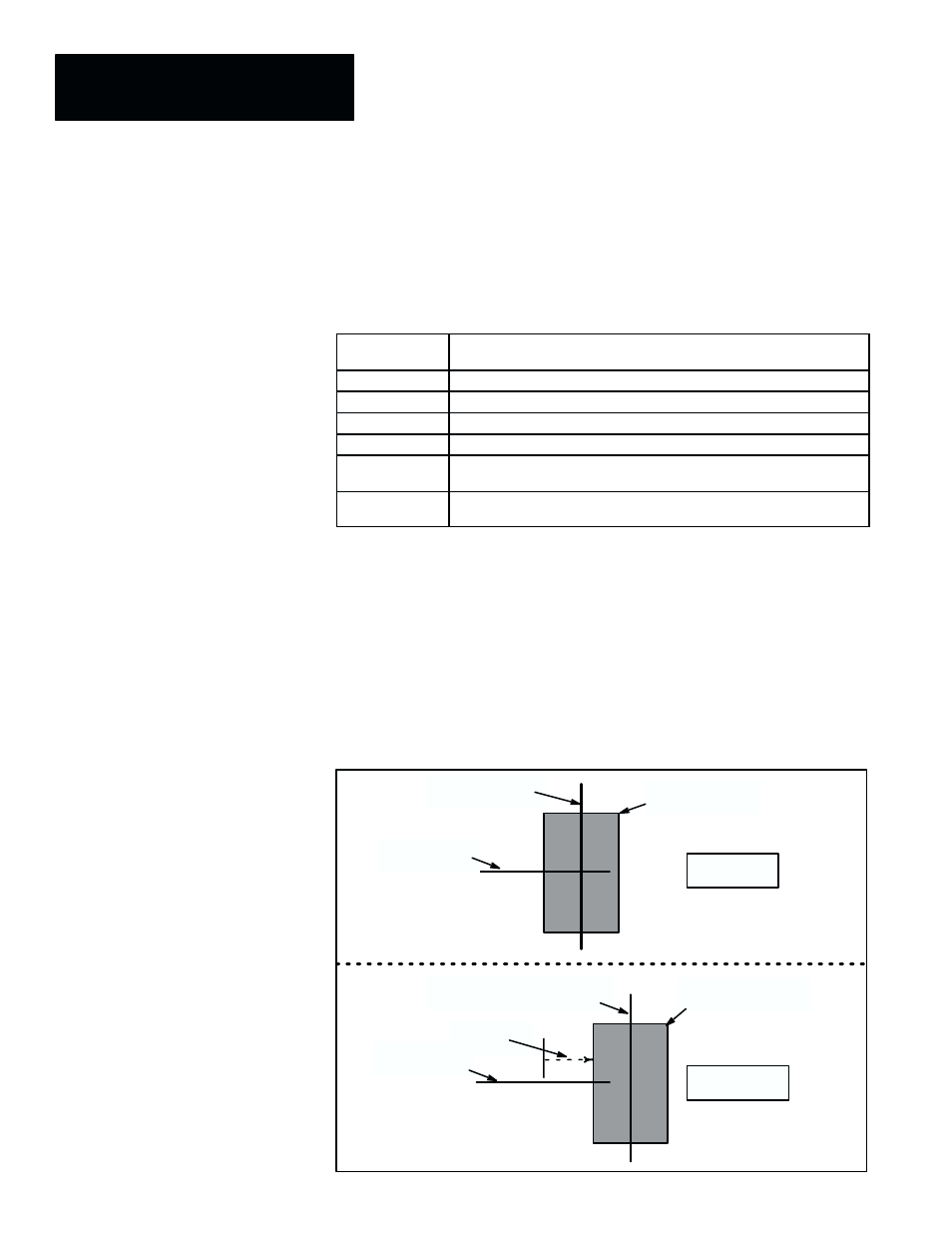

X only

The X only operation consists of a single reference line that lies along the

horizontal (X) axis of the image field. X only is appropriate in applications

where workpiece shift is expected in the X–axis, but not in the Y–axis.

Figure 6.3 shows an X only reference line detecting X–axis workpiece shift

and applying X–axis shift to a line gage.

Figure 6.3 Example: Using an X Only Reference Line Operation

INSPECTED

POSITION

Workpiece:

nominal position

Line gage:

original position

Workpiece:

position after shift

Workpiece

shift

NOMINAL

POSITION

X–axis

reference line

X–axis

reference line

Line gage: with X–axis

shift compensation applied