Rockwell Automation 5370-CVIM2 Module User Manual

Page 100

Chapter 4

Inspection Configuration

4–14

Minimum Time

The

Minimum Time

field enables you to specify a fixed minimum time

interval (in milliseconds) between the start of an inspection and the

availability of inspection results. The effect is to delay the inspection results

in order to ensure that they are always available to a host system on a timely

basis. The valid range for the time interval is 0 to 5000 milliseconds.

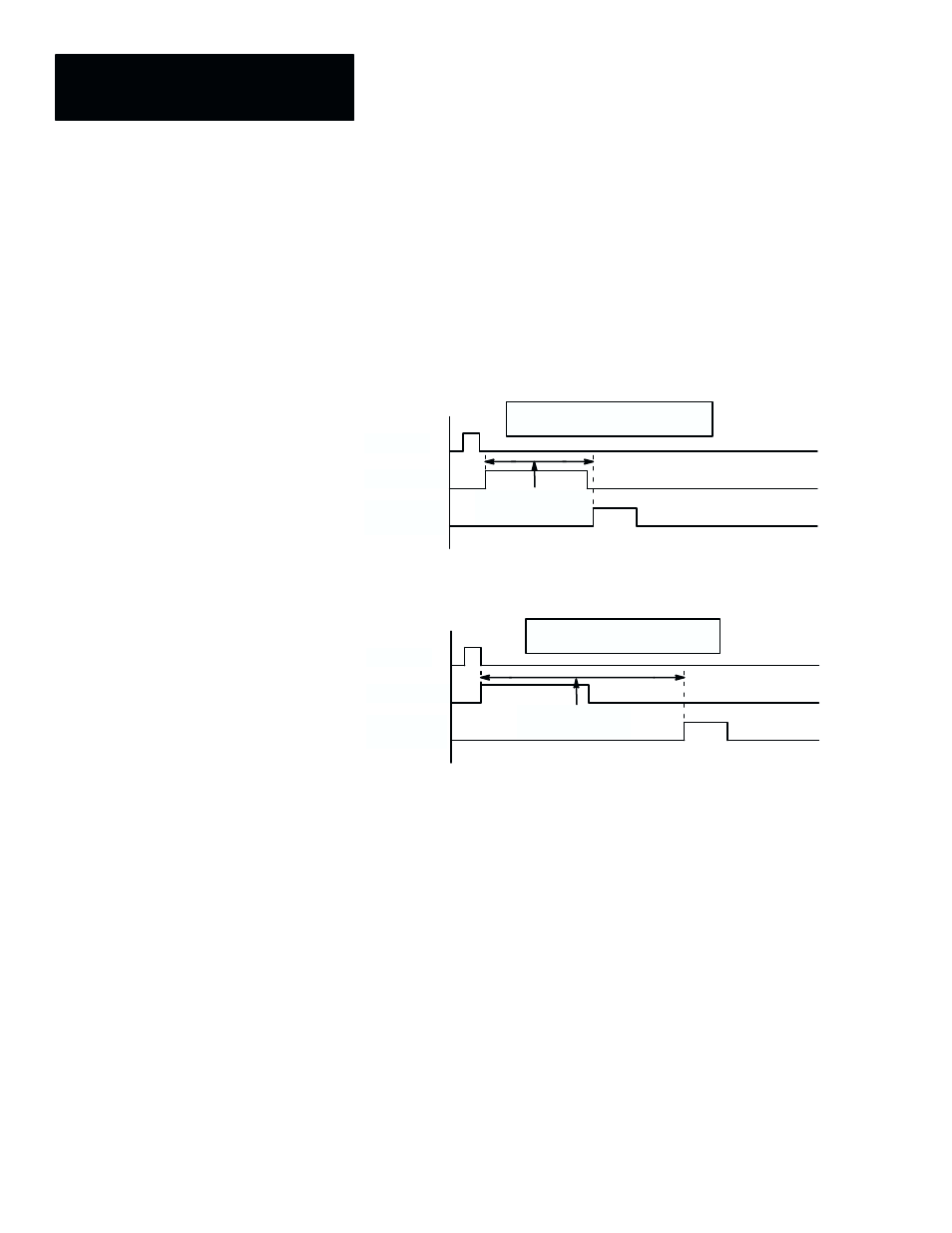

The relation of the inspection start to the inspection results without a fixed

minimum time interval (that is, a setting of 0) is shown below:

Interval varies

with inspection

Trigger

Inspection

Inspection

results

Example of timing without

fixed minimum time interval:

The relation of the inspection start to the inspection results with a fixed

minimum time interval (that is, a setting of more than 0) is shown below:

Trigger

Inspection

Inspection

results

Example of timing with

fixed minimum time interval:

Fixed minimum

delay interval

Samples

The

Samples

field enables you to select an appropriate “sample” size,

ranging from 0 to 65535, for each toolset in a configuration. This value

determines the number of “sample” inspection results that the CVIM2 system

must acquire in order to calculate statistical data for a particular tool. (Note

that this function applies only to a tool for which statistics collection can be

selected, such as a window tool, and for which the

Statistics

box has been

checked in the

Options

selection panel for that tool.)