Strain control calculations – MTS Series 793 User Manual

Page 370

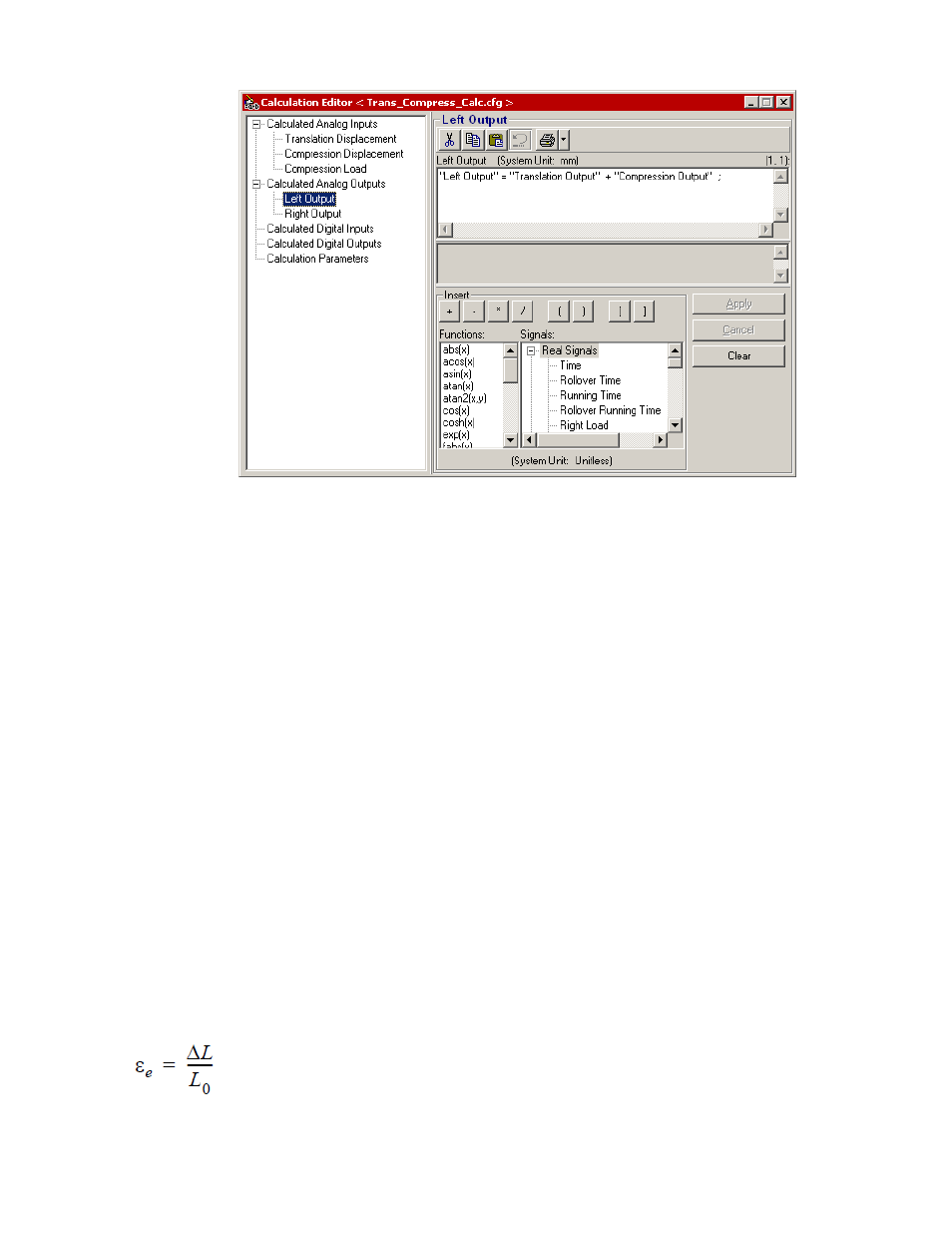

b) Select the calculated output signal from the list for the first servovalve (Left Output), then enter the

required equation in expression window:

“Left Out” = “Translation Output” + “Compression Output”

c) Select the calculated output signal from the list for the second servovalve (Right Output), then enter

the required equation in expression window:

“Right Out” = “Compression Output” - “Translation Output”

Strain Control Calculations

Problem

While testing a metallic specimen in compression, you need to keep deformation constant by keeping the

true strain rate constant.

Solution

Create a true strain control mode by using a calculated true strain feedback signal. This calculated feedback

signal, used by the controller’s summing junction to close the control loop, is a “virtual” signal calculated from

other signals and constants.

Assuming a clip gage is measuring crack opening displacement (COD), create a second calculated signal

called engineering strain (εe). The clip gage measures the change in gage length, then engineering strain is

calculated using the following equation:

Where:

370 MTS Series 793 Control Software

Calculated Signals