16 auxiliary means – Lenze DSD User Manual

Page 409

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

409

16

Auxiliary means

16.1

Auxiliary means integrated in the DSD

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

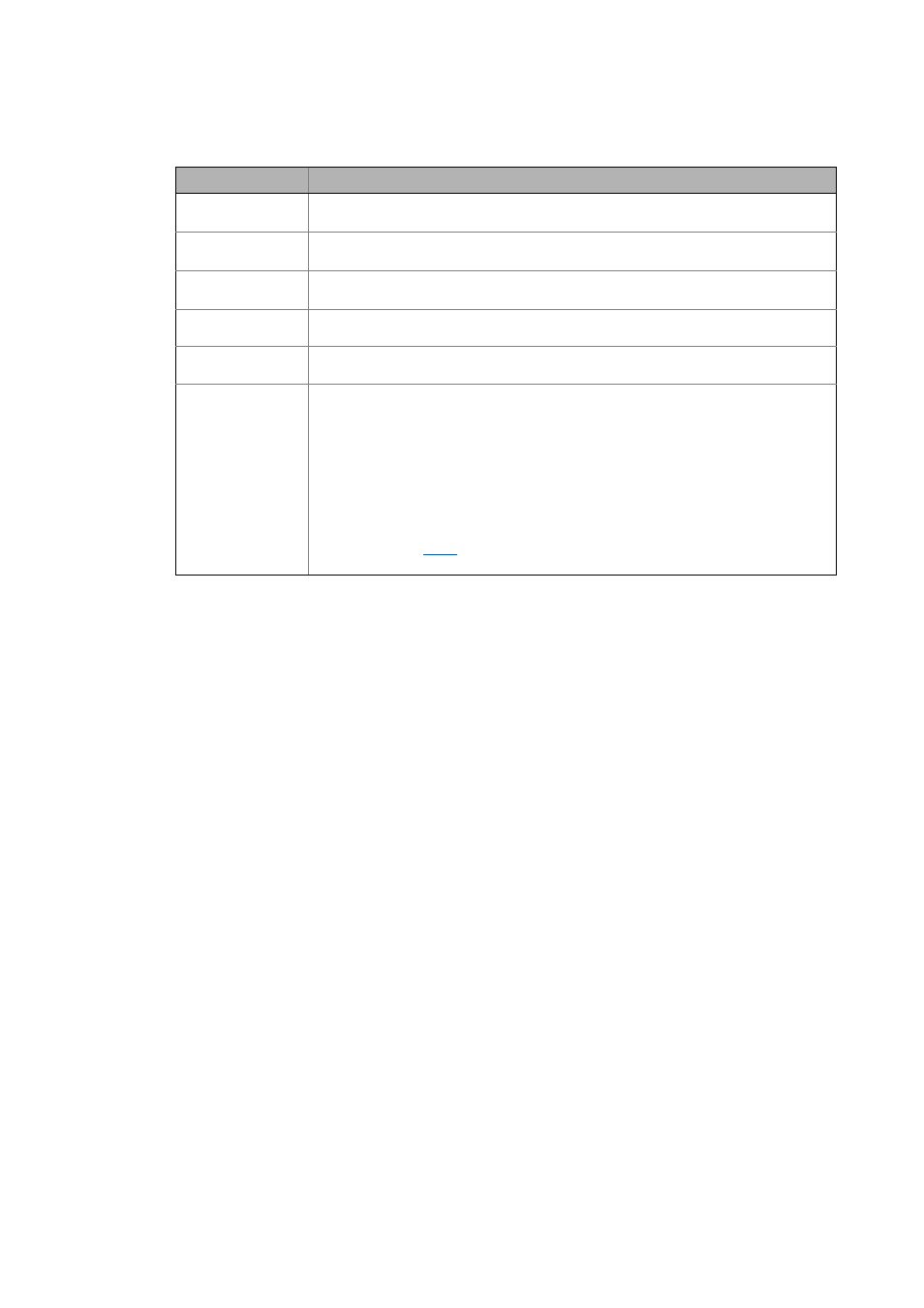

Input field

Meaning

Field

Selection of the field to be calculated.

• If "Direct entry" is selected, the mass value of the field in entered directly.

Designation

Name of the field

• Optional input for easier identification of the different fields.

Rotary axis, diame-

ter, length, etc.

Input parameters for the calculation

• The input parameters depend on the field selected.

Mass

When selecting the option Mass default, the mass, instead of the further input parameters,

can be directly preselected for the calculation.

Distance

When selecting the option Use parallel-axis theorem, here the distance for the parallel dis-

placement of the axes can be preselected.

d1/r1

d2/r2

When selecting the option Speed adaptation to v=const reference n(d1), a conversion to an-

other reference diameter/radius can be effected.

• In this connection, the circumferential speed remains constant at a changing speed.

• Example 1:

The mass inertia of a deflection pulley/roller is to be apportioned to the driving pulley.

The driving pulley and deflection pulley both feature different diameters.

• Example 2:

The carrying rollers of a conveyor belt are to be summed up with the drive roll and the de-

flection roller of the conveying belt to a combined inertia.

• Example 3:

As shown in fig.

, the total inertia of a belt transmission is to be calculated with re-

gard to the output end (general ratio).