7applications – Lenze DSD User Manual

Page 125

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

125

7

Applications

7.9

Hoist drive with counterweight

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Ascertainment of the height difference

For the stationary torque the maximum height difference Δh is required.

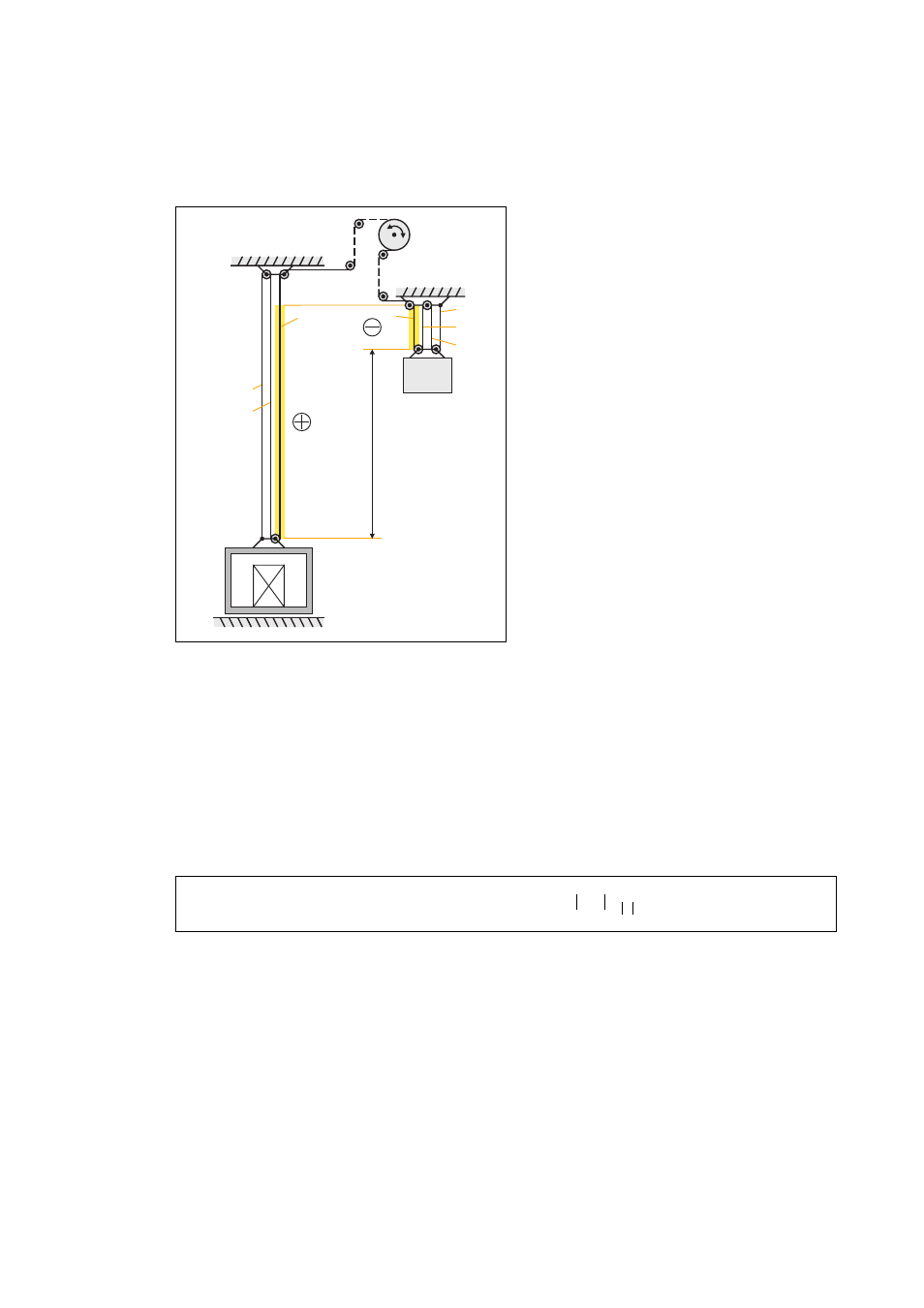

[7-100] Determination of Δh

Torque loss

For including the losses for the hoist the friction torque is calculated from the individual efficiencies.

When carrying out a dimensioning process with a user-definable motion profile, the efficiency for a

travel with the maximum stationary torque is assumed.

• The sign is considered with the fraction n/|n|.

• The friction of the cable rolls is considered as efficiency η

Pll

in a simplified manner. The efficien-

cy depends on the number of cable rolls, the reeving, and the efficiency of the individual rolls.

• The following equation calculates the torque loss in generator and motor mode:

[7-101] Equation 8: Torque loss

• The height Δh usually is the height differ-

ence from the cable end of the counter-

weight to the cable end of the payload at

the lowest position of the payload or the

counterweight.

• The yellow highlighted cable sections

(+) are decisive for the steady-state

torque.

• The cable sections (+, +) cancel

themselves out or are borne by the mount-

ing parts .

Δh

?

?

?

?

M

th

1

η

Gdn

η

Pll

η

Cor

⋅

⋅

-----------------------------------------

1

–

max M

sds

(

) nn------

⋅

⋅

=