11 drive dimensioning – Lenze DSD User Manual

Page 334

11

Drive Dimensioning

11.4

Lenze gearbox selection

334

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.4.1.2

Alternating load and repeated load cycle with regard to toothed gearboxes

In case of a torque reversal (sign reversal), the gearbox is operated with alternating load. In case of

a periodic alternating load (frequently, regularly), the max. permissible torque M

max,out

is evaluated

with the alternating load factor k

alt

.

Alternating loads are calculated in the DSD and considered in the drive dimensioning phase.

If the alternating load was not considered, the gearbox would be operated in the fatique strength

range. For a highly dynamic application with a cycle time of 1 s, the gearbox would have reached

the end of the fatigue strength after an operating time of less than 1000 h.

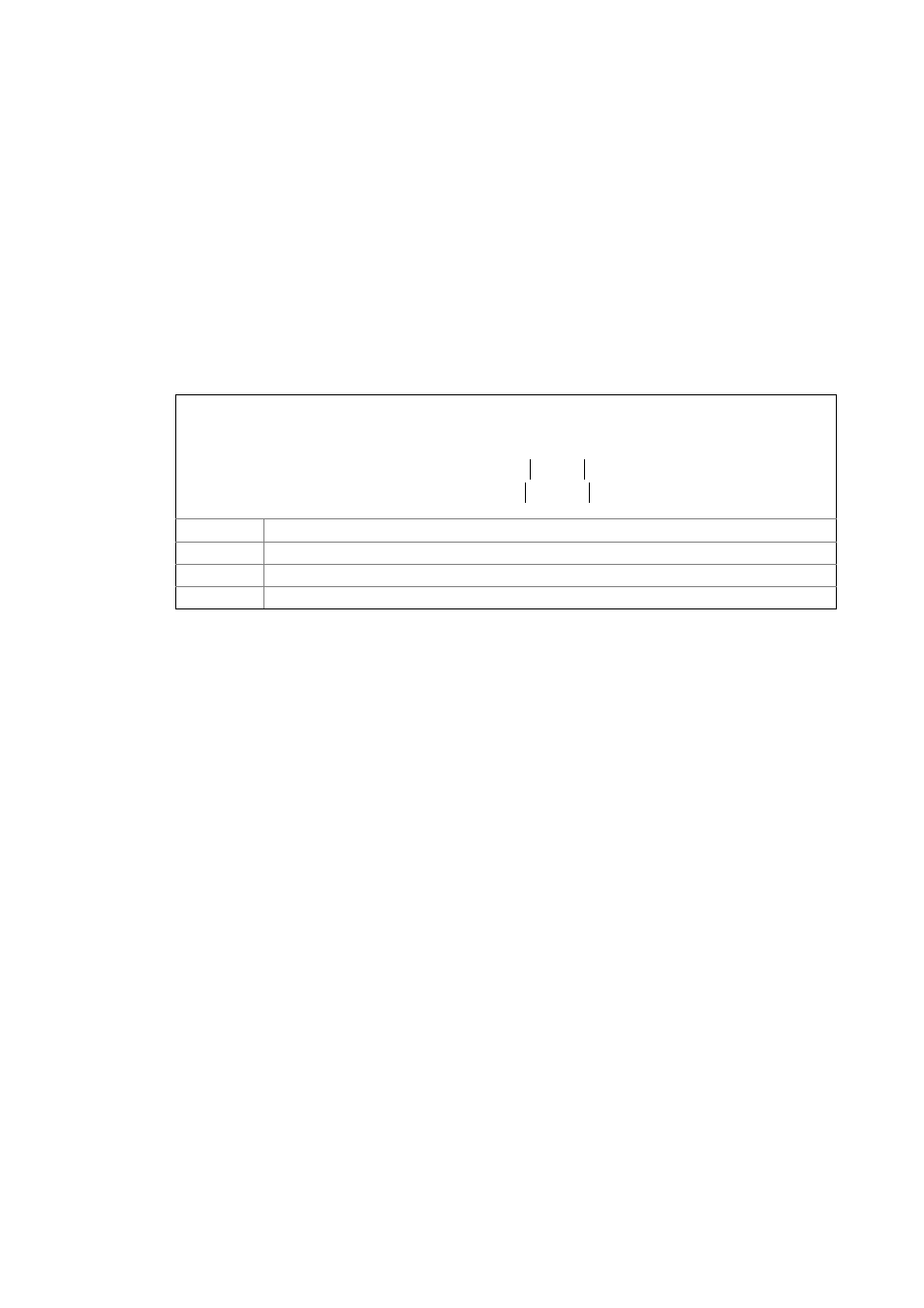

Calculation of the alternating load

[11-11] Calculation of the alternating load

M

max,out

Max. permissible torque at the output end

M

alt,out

Max. torque at the output end in opposite direction to M

max,out

(|M

alt,out

|

≤ |M

max,out

|)

M

per,out

Rated torque at the output end

k

alt

Alternating load factor

M

max,out

M

per,out

k

alt

--------------------

≤

k

alt

1 0.4

M

alt,out

M

max,out

-------------------------

⋅

+

=