7applications – Lenze DSD User Manual

Page 214

7

Applications

7.22

Winding drive for rewinder/unwinder

214

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

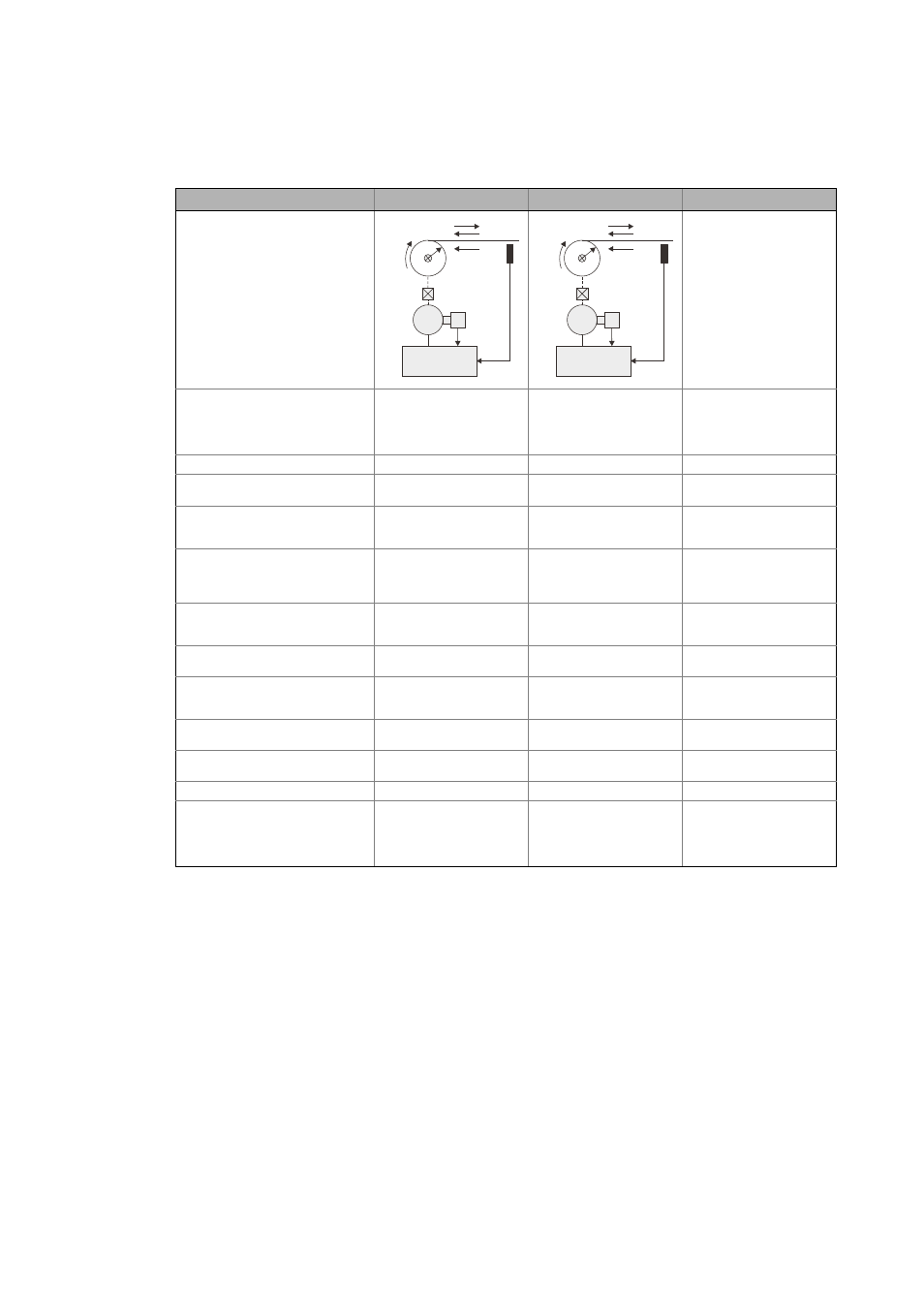

Comparison of tension-controlled winder control modes

Requirement

Tension control (M)

Tension control (n)

Note

Winder control mode

Description

Torque-controlled mode with

compensation for friction and ac-

celeration

Speed-controlled mode (option-

ally with compensation for fric-

tion and acceleration to the

torque setpoint)

Both control modes are suitable

for demanding winding applica-

tions with a high consistency in

tensile force and large setting

ranges

Tensile force / torque setting range

max. 100

no upper limit

Acceleration behaviour

++

++

Both modes feature acceleration

compensation

Behaviour in the case of tensile force sensor

failure

++

(operation possible in case of an

emergency)

–

(operation not possible)

Combined winder control modes:

Closed-loop controlled for lower and open-

loop controlled for upper tensile force set-

ting ranges

++

–

Application in case of a large

range of materials with a large

tensile force setting range

Control mode as a function of material elas-

ticity

suitable for no or low material

elasticity (e.g. metal strips, foils,

plates, glass non-woven)

suitable for medium material

elasticity, e.g. paper, films, coated

composite material

Tensile force sensor is a pathless

detection system

Influence of the friction on the tensile force

/ torque setting range

0

(great influence)

++

(little to no influence)

Suitable for unwinders with eccentric reels

++

(non-sensitive behaviour)

/

(sensitive behaviour)

If stored for a longer period of

time, reels may deform eccentri-

cally

System management in case of material

crack

+

++

Control engineering requirements

Medium

High

Adaptations to a variable mo-

ment of inertia, variable speed

Required encoder resolution

Medium

High

Accuracy for the detection of the line speed

Medium

High

Reasons for the differences be-

tween the actual and the detect-

ed speed: coated squeegees, slip

between material and roll, toler-

ances in material thickness

++ Very well suited

/

Suitable with restrictions

+ Well-suited

–

Not suitable

0 Suited

v

F

n, M

r

M

3~

Inverter

M = f(F, r)

n = f(v, r)

F

act

v

F

n, M

r

M

3~

Inverter

M = f(F, r)

n = f(v, r)

F

act