1 symbols used, 2 data for the entry, 1 diameter of traction sheave – Lenze DSD User Manual

Page 127: 2 reeving, load, Data for the entry, 7applications

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

127

7

Applications

7.9

Hoist drive with counterweight

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.9.1.1

Symbols used

7.9.2

Data for the entry

7.9.2.1

Diameter of traction sheave

7.9.2.2

Reeving, load

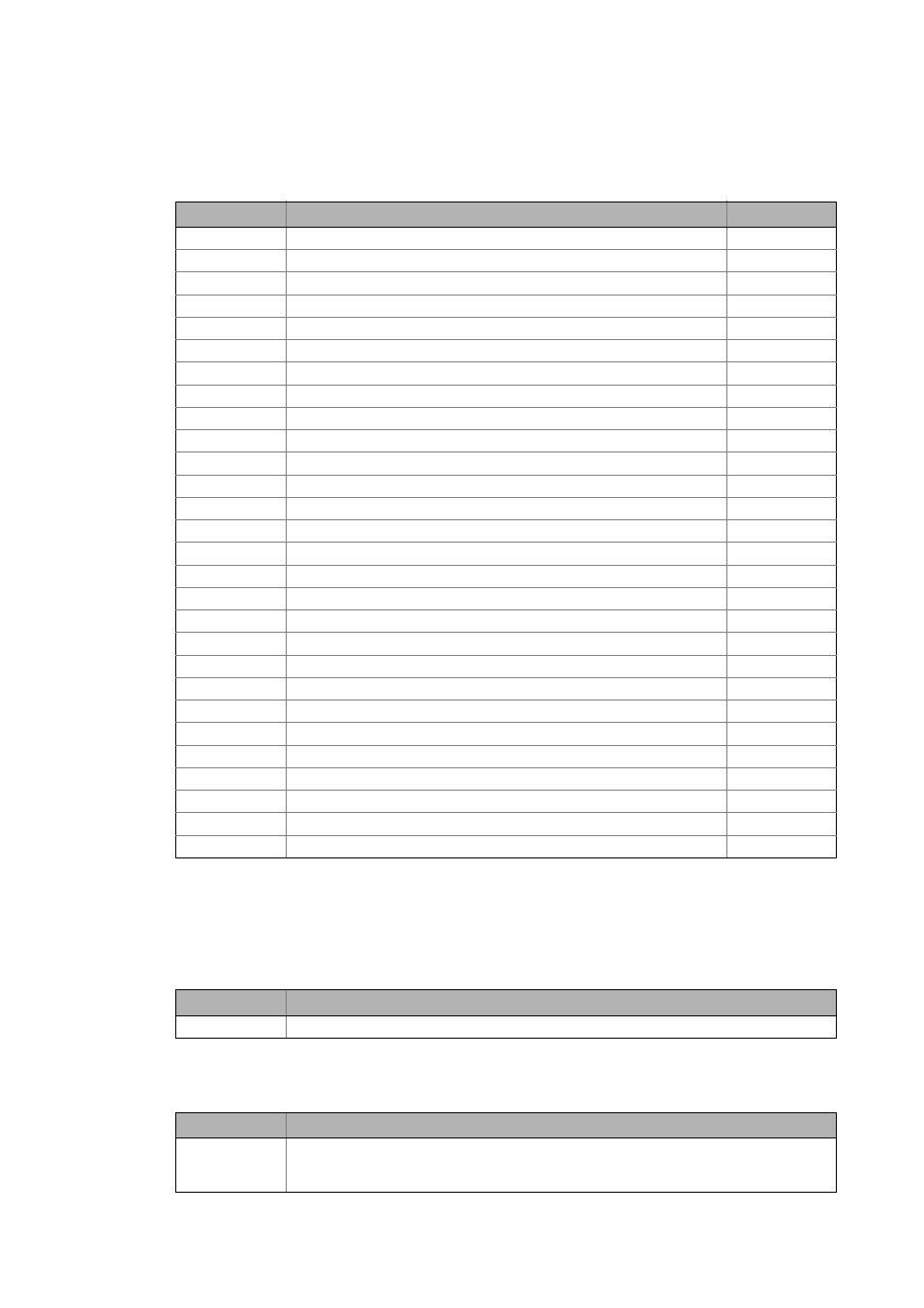

Symbol

Description

Dimension unit

d

Effective diameter of driving pulley

mm

d

Cor

Diameter of traction sheave

mm

d

Rop

Cable diameter

mm

F

add

Additional force

N

g

Gravitational acceleration (g = 9.81 m/s

2

)

m/s

2

Δh

Height difference for the determination of the stationary torque

m

J

add

Additional moment of inertia

kgm

2

J

Stationary moment of inertia without payload mass

kgm

2

J

sum

Total moment of inertia with payload mass

kgm

2

N

L

Reeving of the pulley block with regard to the payload

N

Ctw

Reeving of the pulley block with regard to the counterweight

l

Rop

Cable length

m

m

L

Mass of the payload

kg

m

Ctw

Mass of counterweight

kg

m

Cbn

Mass of the hoisting cage for the payload

kg

m

Rop

Cable mass

kg

m

acv,Rop

Active cable mass for stationary torque

kg

M

App

Required torque of the application

Nm

M

sds

Stationary torque

Nm

M

th

Torque loss

Nm

n

Speed of the driving pulley

rpm

v

Speed of the payload/hoisting cage

m/min

v

Ctw

Speed of the counterweight

m/min

α

Angular acceleration of the driving pulley

rad/s

2

η

Gdn

Shaft efficiency

η

Pll

Efficiency of the cable rolls

η

Cor

Efficiency of the driving pulley

ρ

Rop

Specific cable weight

kg/dm

3

Symbol

Description

d

Cor

Diameter of traction sheave

Symbol

Description

N

L

The reeving of the cable to the payload.

• The reeving is the ratio of the cable velocity of the winding drum to the lifting speed of the

payload.