2 servo inverters, 10 structure of the drive axis, 3 drive concept 296 – Lenze DSD User Manual

Page 296

10

Structure of the drive axis

10.3

Drive concept

296

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

10.3.4.2

Servo inverters

Servo inverters are highly dynamic current-controlled systems for speed, torque, or position control.

They are characterised by a high speed accuracy, a great torque setting range, and a high overload

capacity. For the operation a speed feedback is always required.

• Position-controlled systems are suitable for drive tasks as e.g. positioning, electronic gearbox or

electronic cam.

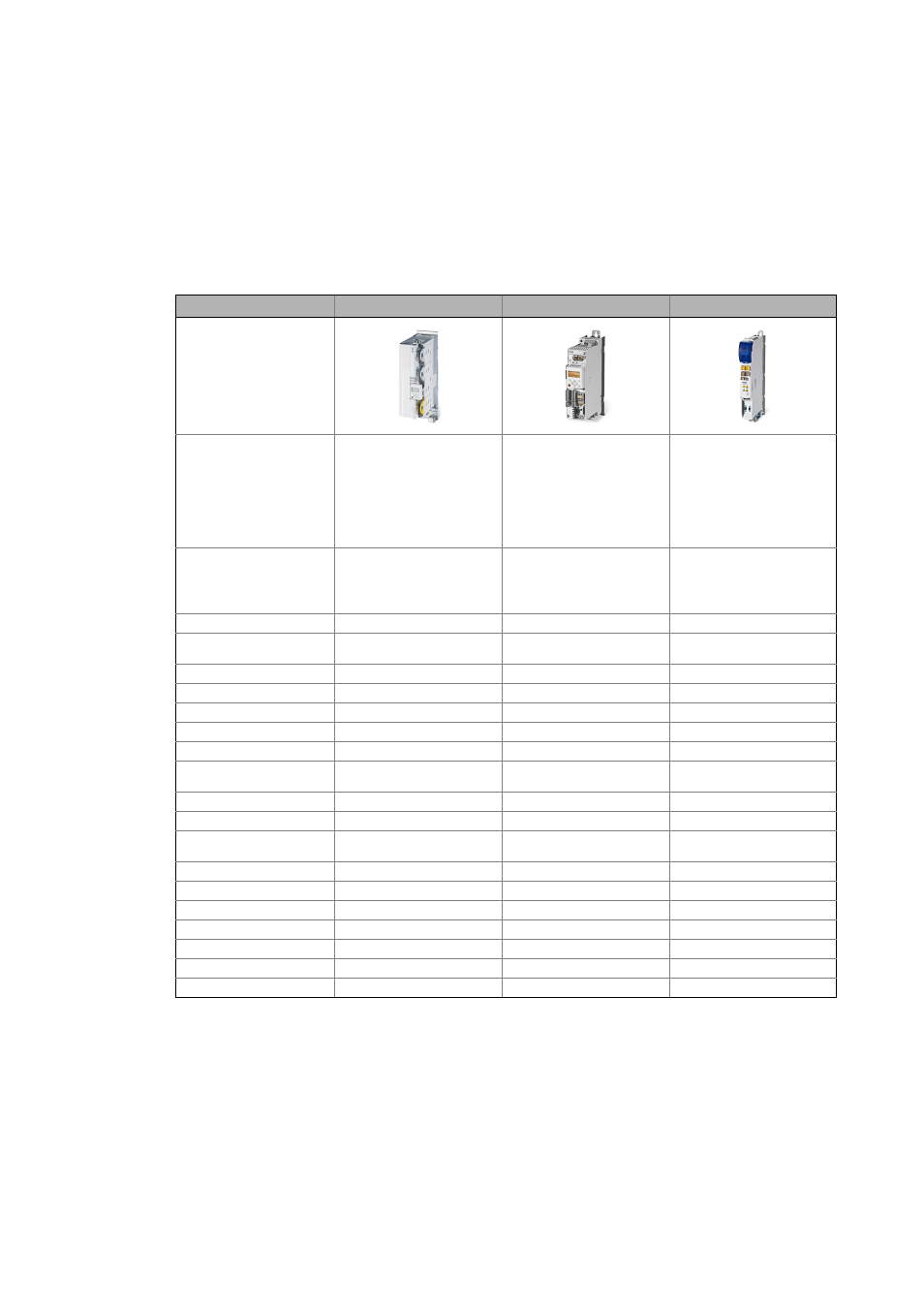

Servo Drives 9400

8400 TopLine

i700

Illustration

Short description

Intelligent servo inverter for single-

axis and multi-axis applications,

function block structure that can be

freely interconnected, activation via

digital inputs/outputs and/or field-

bus, modular safety functions, inno-

vative backplane system, pluggable

memory chip for the parameter set

Servo inverters for synchronous and

asynchronous servo motors, suitable

for speed and position-controlled

applications and positioning appli-

cations, multi encoder input, option-

ally with integrated safety

functions, fieldbus communication,

pluggable memory chip for the pa-

rameter set

Servo inverter for single-axis and

multi-axis applications, compact de-

sign and connection system, flexible

motor control for synchronous and

asynchronous motors, multi-axis

system with central supply

Voltage range/power range

Single Drive:

3 AC 180 … 550 V: 0.37 … 370 kW

DC 260 … 775 V: 0.37 … 370 kW

Multi Drive:

DC 260 … 775 V: 0.37 … 15 kW

1 AC 180 … 264 V: 0.25 … 2.2 kW

3 AC 320 … 550 V: 0.37 … 45 kW

Power supply module:

3 AC 320 … 528 V

DC 260 … 775 V

Axis module:

DC 260 … 775 V: 0.75 … 15 kW

Approvals

CE, UL508C

CE, UL, GOST-R, RoHS

CE, UL508C

Permissible power systems

TN, TT, IT

TN, TT, IT,

RoHS-compliant

TN, TT, IT

Switching frequencies

1, 2, 4, 8, 16 kHz

2, 4, 8, 16 kHz

4, 8, 16 kHz

Mechanical design

Built-in unit

Push-through technique

–

(up to 15 kW)

Cold plate technique

–

(up to 22 kW)

Installation backplane

(SingleDrive up to 11 kW)

(MultiDrive up to 15 kW)

–

–

Enclosure

IP 20

IP 20

IP 20

Operation in generator mode

Integrated brake resistor

(SingleDrive, power supply modules)

External brake transistor

–

–

–

Regenerative

–

–

Control types

V/f control

Vector control (encoderless)

–

Synchronous motors (encoderless)

–

–

Servo control