2 tips for optimising the drive systems, 14 energy efficiency – Lenze DSD User Manual

Page 382

14

Energy efficiency

14.2

Tips for optimising the drive systems

382

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

14.2

Tips for optimising the drive systems

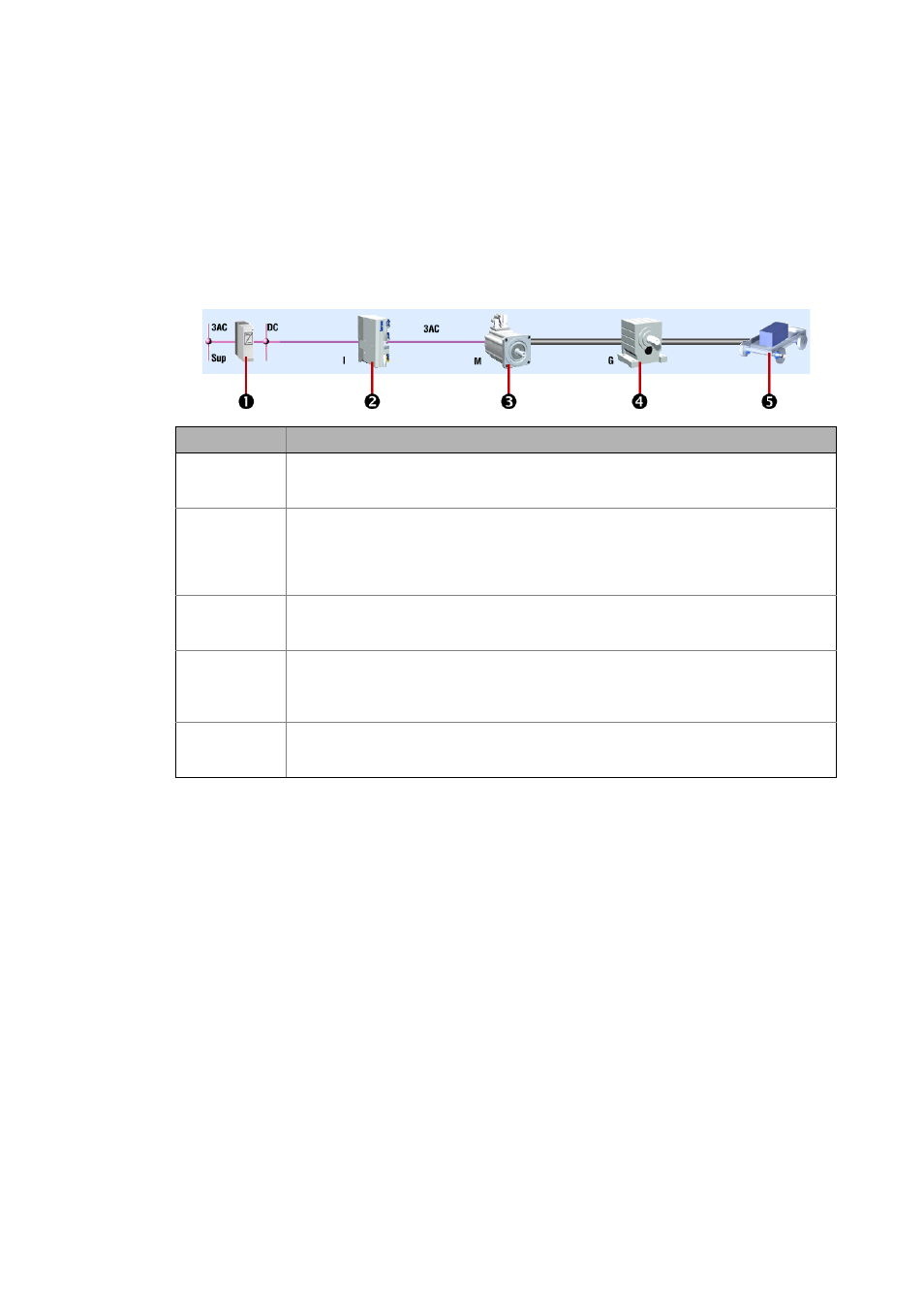

Generally the following applies:

• Avoid overdimensioning without extremely overloading the components.

• The longer the operating time of the drive, the greater are the saving effects.

Further possibilities for an energy-efficient dimensioning of the drive system can be found in the

following table.

Legend

Possible dimensioning

Supply / feed

• In DC-bus connection,

• with power recovery into the mains.

Inverter with

• servo control

• low switching frequency,

• 2-switch modulation (e.g. Inverter Drives 8400),

• VFCplus eco control mode.

Motor

• Use synchronous motor, IE2 motor or 120-Hz motor

• Utilise speed setting range, e. g. 87 Hz operation for standard motors

Gearbox with

• a high efficiency,

• a low number of stages,

• a low input speed.

Application with

• low friction,

• low inertia.