11 drive dimensioning – Lenze DSD User Manual

Page 336

11

Drive Dimensioning

11.4

Lenze gearbox selection

336

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

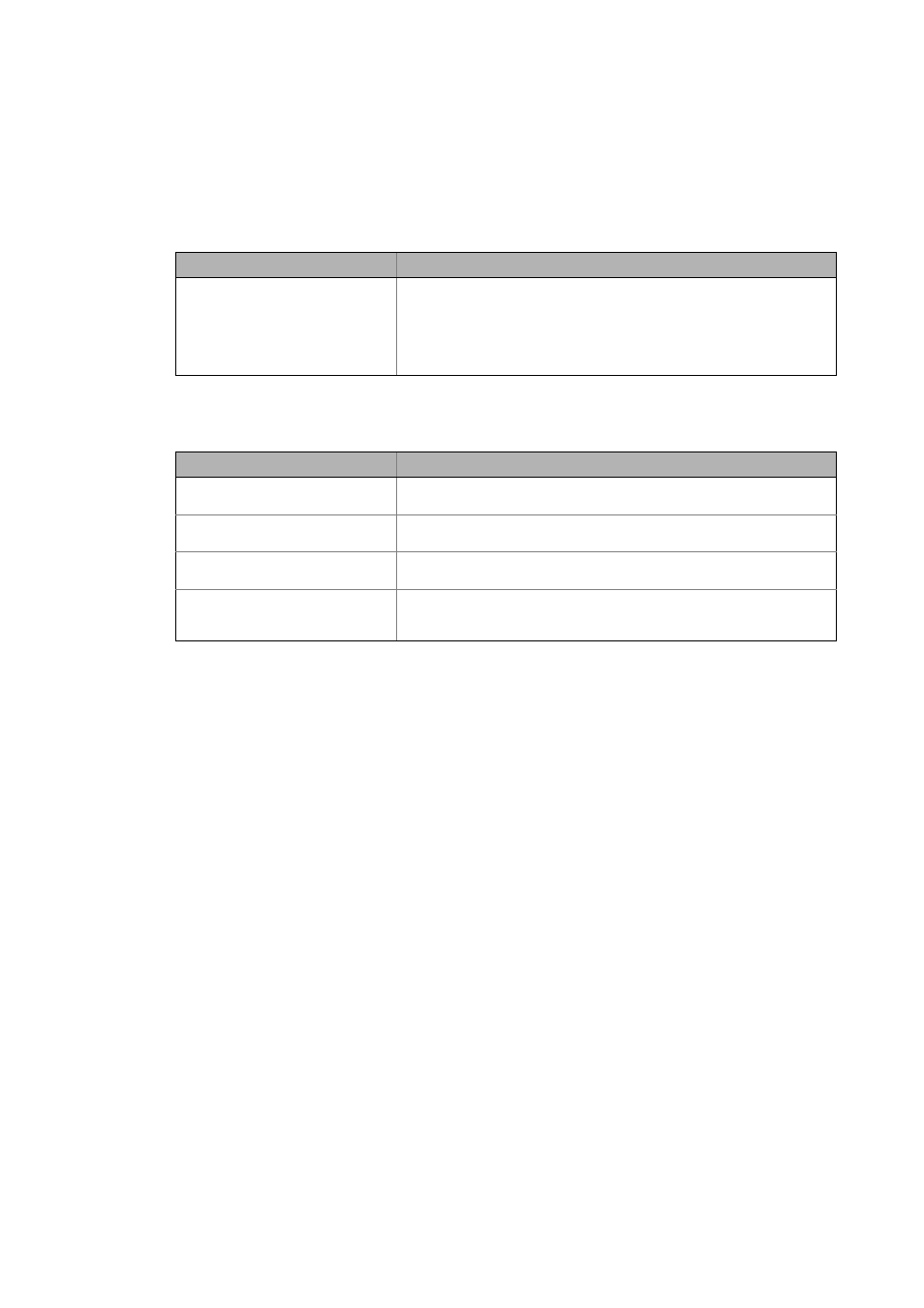

Typical applications with alternating load

All applications are affected for which a torque reversal with a sign reversal can be generated via the

motion profile. In practice, however, these applications can be narrowed down fairly well.

The applications given in the table can be dimensioned with the DSD.

Typical applications without alternating load

For the following applications, an operation with alternating load is improbable.

Application

Information

Motion applications:

Basically all motion applications (wheel drive, belt drive, rack drive, spindle

drive, rotary table drive, hoist drive with counterweight, general rotary drive

with motion profile) are affected, irrespective of whether they are actuated

by means of frequency inverters or servo inverters.

• Usually there is always a sign reversal in the case of the torque at the out-

put end.

Application

Information

Hoist drive without counterweight

For cable-guided hoists without counterweight no periodic alternating load

occurs. Only a repeated load cycle can occur.

Continuous conveyor

For continuous conveyors, no periodic alternating load occurs. Only a repeat-

ed load cycle can occur.

Pump, fan

For pumps and fans, no periodic alternating load occurs. Only a repeated

load cycle can occur.

Synchronous drive

Synchronous drives generally are quasi-stationary drives. There is no period-

ic alternating load. Usually there is only a repeated load cycle, unless these

drives are traversed in intermittent operation.