22 winding drive for rewinder/unwinder, 1 rewinder (single), Rewinder (single) – Lenze DSD User Manual

Page 198: 7applications

7

Applications

7.22

Winding drive for rewinder/unwinder

198

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7.22

Winding drive for rewinder/unwinder

7.22.1

Rewinder (single)

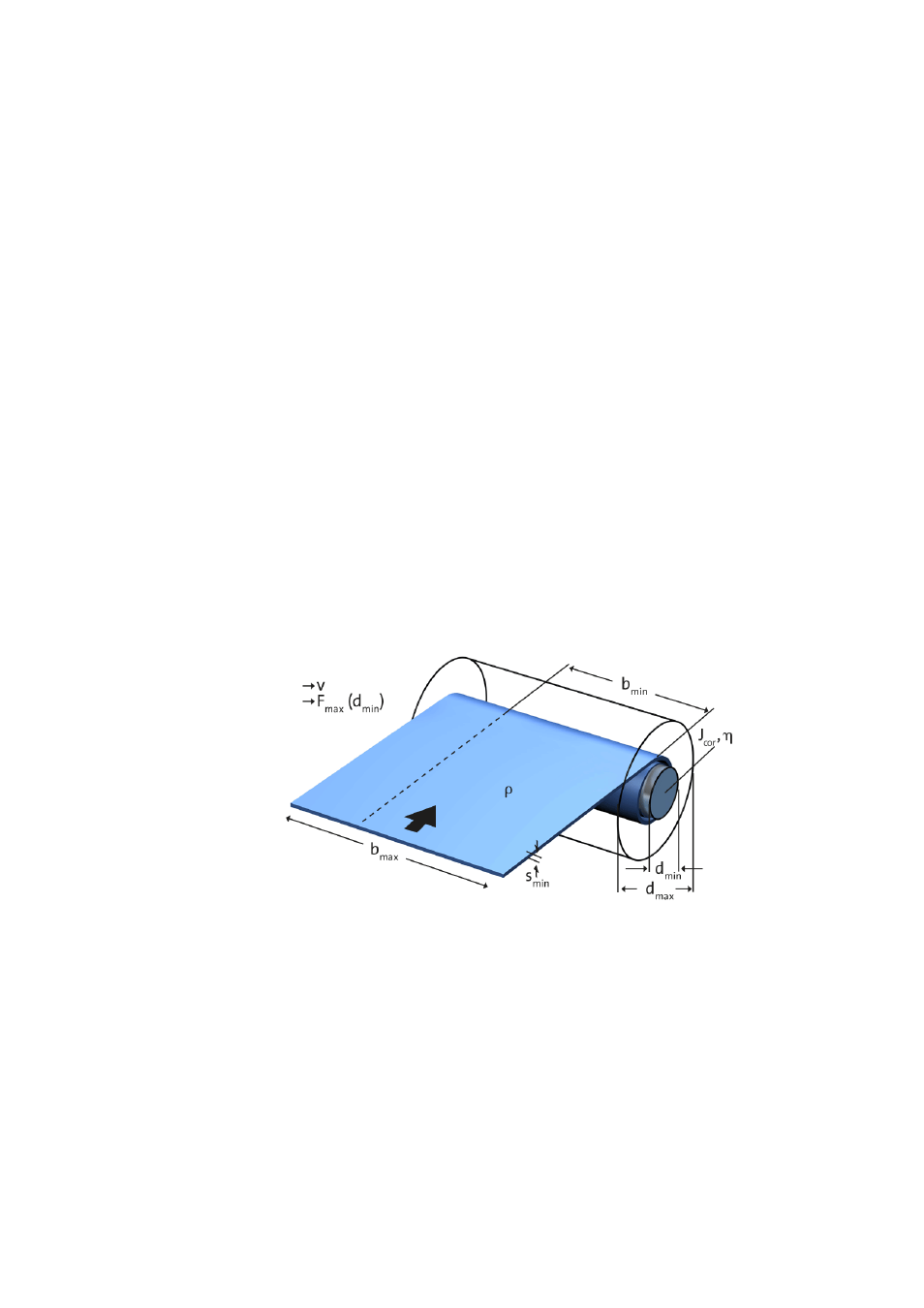

Rewinders are used in many production processes. They are able to store continuous material after

the machining process.

The roller of a single rewinder can only be changed at standstill. The winding drive is braked to

standstill and then accelerated to production speed again after changing the roller. A web accumu-

lator serves to change the roller without the need for a production downtime. When the winding

drive is at standstill, the web accumulator stores the produced material.

Materials to be processed are e.g.: homogeneous webs (e.g. paper webs), fabrics, meshwork, wires,

threads or fibres. From a mathematical point of view, the wound up material is a spiral. Depending

on the application range and industry sector, the spiral is called reel, spool, coil or tree.

There are two winding technologies:

• Lay-up winding (e.g. foils, paper, plates).

• Filament winding (e.g. threads, fibres, wires, cables). This winding technology is not supported

by DSD.

The requirements for the winding drive depend on the winding material and may be very high:

• No impacts on the winding material during the winding process.

• High speed and torque setting ranges.

• Dynamic phase must not have any negative impacts on the tensile force.