6 current derating for inverters, 11 drive dimensioning – Lenze DSD User Manual

Page 352

11

Drive Dimensioning

11.6

Inverters

352

Lenze · Drive Solution Designer · Manual · DMS 4.2 EN · 12/2013 · TD23

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.6.1.6

Current derating for inverters

If small field frequencies (3 ... 5 Hz) occur, the max. output current is limited for some inverters. The

torque calculated is no longer reached.

Effects

•

Applications with low field frequencies

• The current derating has a more serious impact on synchronous machines than on asynchro-

nous machines. Due to the missing slip frequency, in the case of asynchronous machines the 5

Hz threshold is not exceeded so quickly.

• During operation in generator mode the current derating is more distinct than during operation

in motor mode.

• If an output current above the standstill current is required for horizontal drives:

• Acceleration movements: The acceleration distance or time will be slightly longer.

• Braking processes: The braking distance slightly increases.

• DC-injection braking: The braking current is reduced, and thus the braking torque provided

by the inverter is reduced.

• Extruder drives which are accelerated to the target speed during a "cold start" have no notice-

able torque reduction within the first minutes during the acceleration phase and following

constant speed phase. The pinch effect with regard to the current, which might possibly oc-

cur should be taken into consideration during the dimensioning. This applies in particular to

great drive powers, since the slip frequency usually decreases with an increasing rated motor

power.

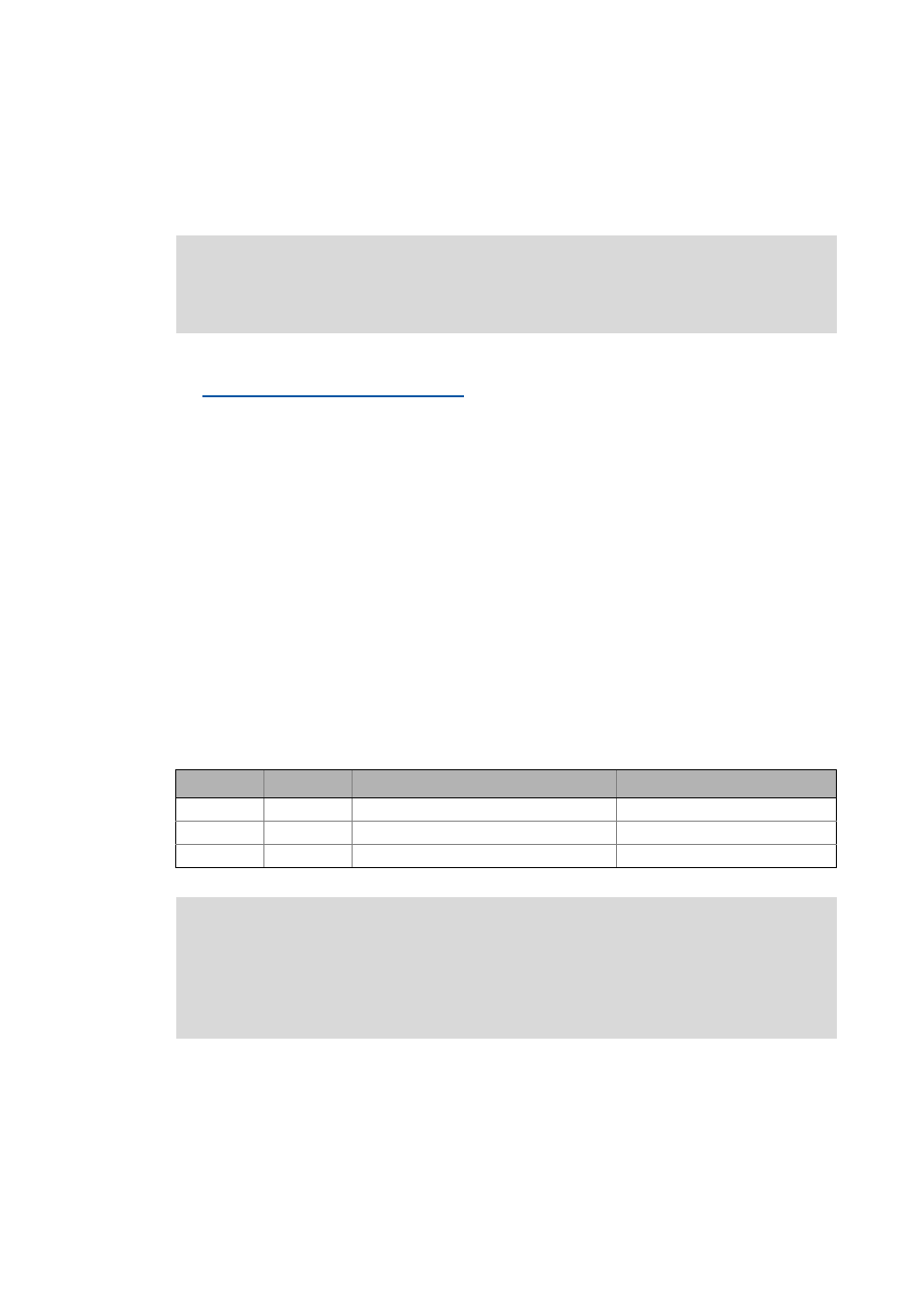

• Slip frequencies of 4-pole asynchronous machines (example):

Note!

The specific restrictions due to the current derating can be found in the respective docu-

mentation for the inverter.

P

n

n

n

Slip speed n

s

(n

0

– n

n

)

Resulting slip frequency f

s

90 kW

1480 rpm

(1500 – 1480) rpm = 20 rpm

0.67 Hz

22 kW

1456 rpm

(1500 – 1456) rpm = 44 rpm

1.47 Hz

4 kW

1435 rpm

(1500 – 1435) rpm = 65 rpm

2.17 Hz

Note!

The DSD takes the output currents specified in the documentation of the inverter

(f

d

> |5 Hz|) as a basis for calculation, and not the standstill currents.

• For passive loads a torque reduction only has a small effect on a greater following er-

ror, and it has no interfering effects on most applications.