External piping to the drive, External piping cleaning – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 77

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

77

Drive Installation

Chapter 2

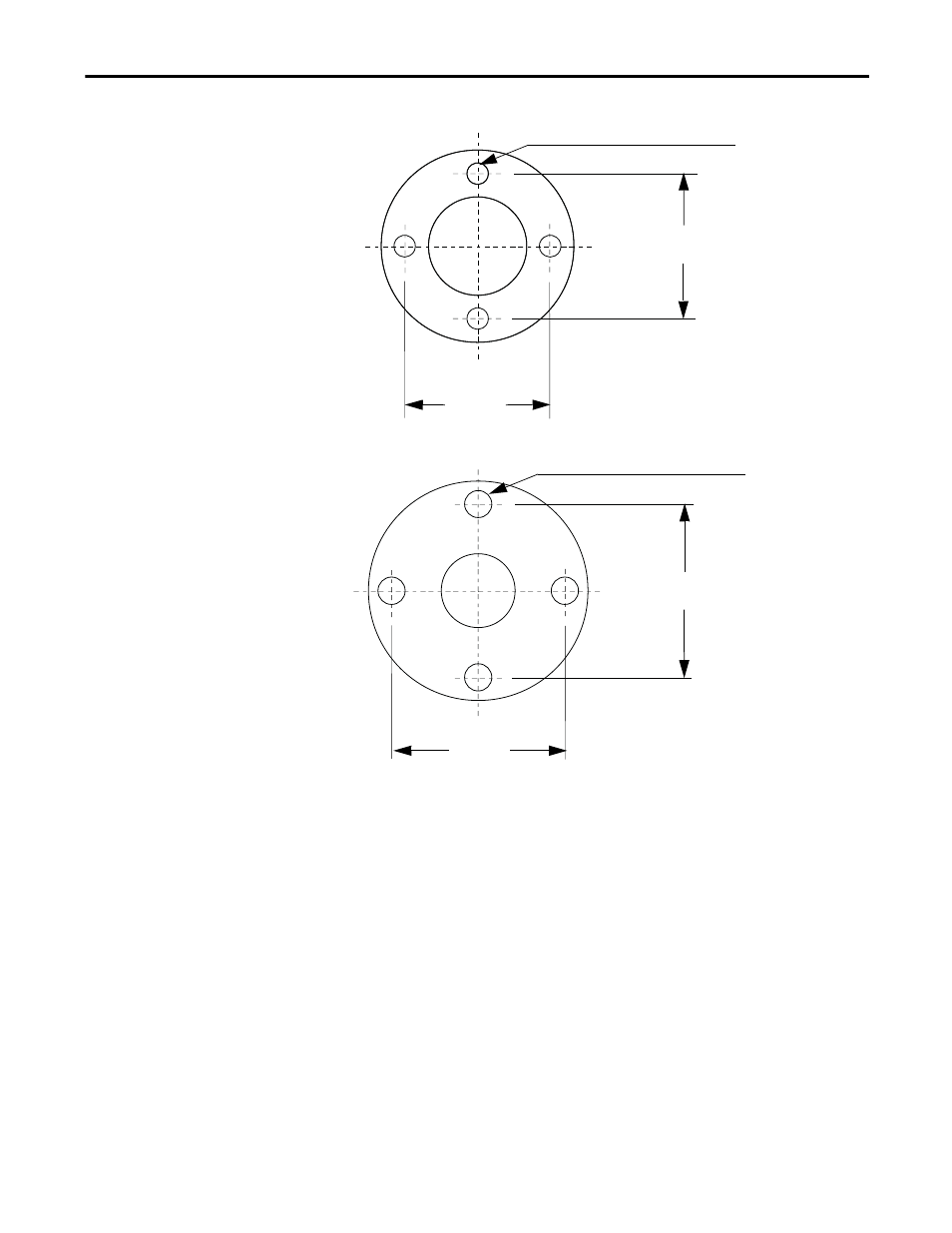

Figure 61 - Drive CPVC Class 150 Flange, 1.5 in. (38.1 mm) (ANSI B16.5; ASTM D4024)

Figure 62 - Drive CPVC Class 150 Flange, 2 in. (50.8 mm) (ANSI B16.5; ASTM D4024)

External Piping to the Drive

External Piping Cleaning

Rockwell Automation liquid-cooled drive piping and heat exchangers are flushed

and cleaned at the factory and piping is capped to prevent contamination. Leave

the drive pipe caps installed until final assembly.

Use stainless steel capped piping and valves to maintain cleanliness before

welding or assembly. Parts must be stored in a clean, dry area.

All external piping must be cleaned and flushed before installation to ensure

proper coolant system and drive pump operation.

98.4 (3.9)

98.4

3.9

14.2 (0.560)

• Dimensions in mm (in.)

• Use M12 (0.5 in.) bolt with

washer. Torque to

27...41 N•m (20...30 lb•ft)

• Torque in a cross pattern,

slowly working toward

torque rating

• The flange used must be a

flat type flange. Raised

flanges may break.

• Dimensions in mm (in.)

• Use M16 (5/8 in.) bolt

with washer. Torque to

27...41 N•m (20...30 lb•ft)

• Torque in a cross pattern,

slowly working toward

torque rating

• The flange used must be a

flat type flange. Raised

flanges may break.

18.7 (0.74)

120.6

(4.7)

120.6 (4.7)