Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 295

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

295

Component Definition and Maintenance

Chapter 5

4.

Remove the load on the clamp head assembly as described in

5.

Two screws secure the board to the chill block. Loosen the captive screws

with a long Phillips screwdriver until the circuit board is free. It may be

necessary to adjust the position of the chill blocks to allow free movement

of the SGCT.

6.

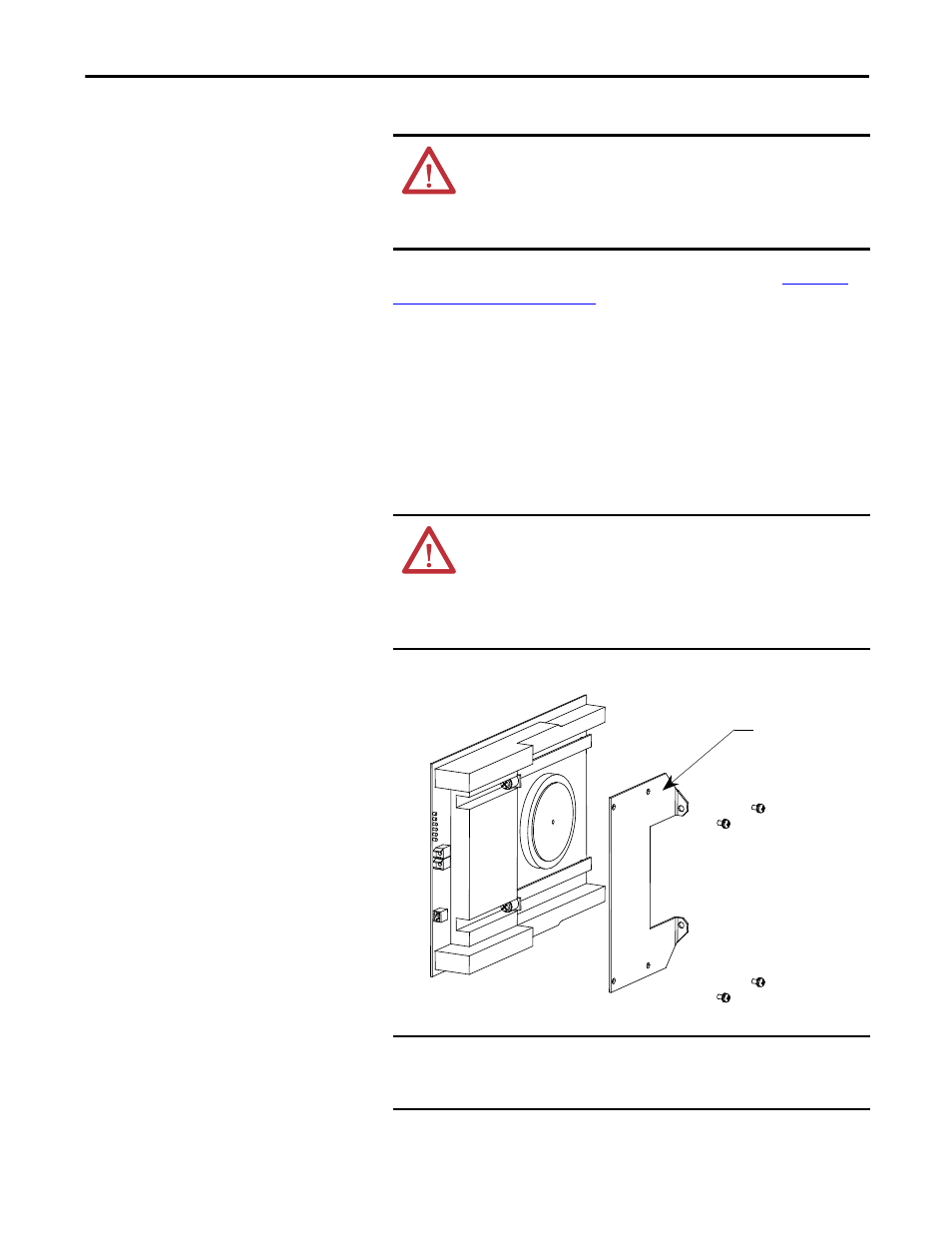

SGCTs can now be extracted by pulling the Gate Driver board forward

between the upper and lower manifolds. Use a Phillips screwdriver to

remove the brace angle of the SGCT. Retain the brace angle and its

hardware.

Figure 244 - Replacing the SGCT – Brace Angle

ATTENTION: The fiber optic cables can be damaged if struck or bent

sharply. The minimum bend radius is 50 mm (2 inches). The connector

has a locking feature that requires pinching the tab and gently pulling

straight out. The component on the printed circuit board should be held

to prevent damage.

ATTENTION: The SGCT can be destroyed or damaged by static charges.

Personnel must be properly grounded before removing the replacement

SGCT from the protective anti-static bag that it is supplied in. Use of

damaged circuit boards may also damage related components. A

grounding wrist strap is recommended for handling sensitive circuit

boards.

IMPORTANT

SGCTs come in matched sets in systems with more than one device per

leg. When replacing the device, it is necessary to replace all devices in

the matched set even if only one has failed.

SGCT Brace