Leakage checks – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 343

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

343

Component Definition and Maintenance

Chapter 5

There are two possible causes of water loss in the drive:

Evaporation

– Up to 99.5% of liquid lost to evaporation is water because of the

chemical properties of the substances in the mixture.

Leaks

– Glycol and water are lost proportionally depending on the concentration

of the substances in the mixture. For example, if the mixture is 60% glycol and

40% water, then any leakage will contain the same proportions of the liquids.

To rectify the problem, add small quantities of water. Measure the freeze

temperature of the coolant after each addition and continue adding until the

desired freezing temperature is achieved.

Leakage Checks

When repairing leaks or working on the stack assemblies, it is highly

recommended that several layers of industrial-grade absorbent pads be placed on

top of the middle and lower stacks to prevent any coolant spills from falling down

on to the lower components, specifically the printed circuit boards.

Most leaks will be visible in the first 30 minutes, and once the system begins to fill

and pressurize, you should be constantly inspecting all fittings and connections

for drips. It is best to have help in checking the inverter and rectifier section, and

the DC Link cabinet. An absorbent cloth is ideal for checking that the coolant is

actually leaking and is not just remnants of the repair.

If a leak is a visible at the threaded joint of a stainless steel fitting and a CPVC

(plastic) pipe, the leak can often be repaired by tightening the joint.

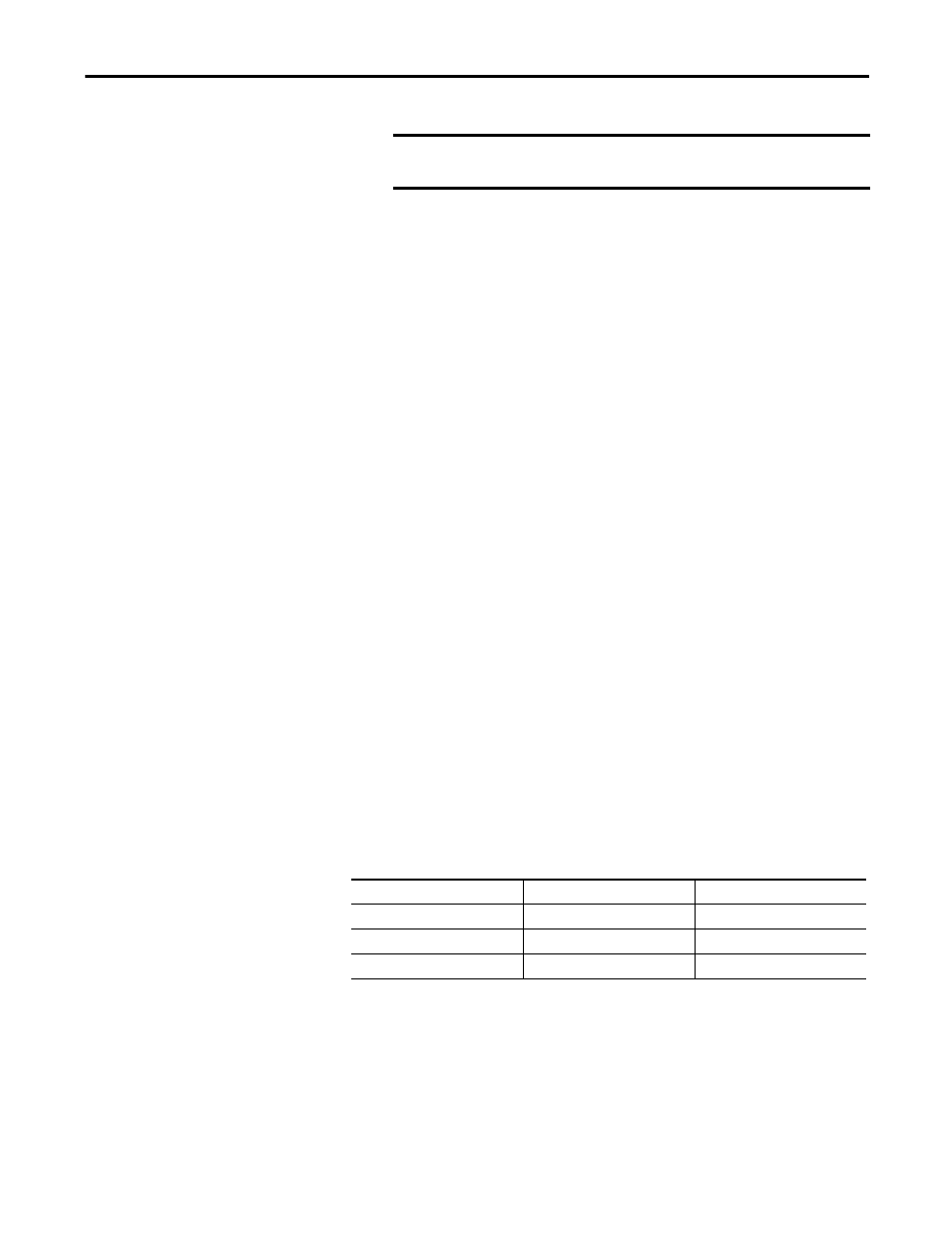

Use the following values of torque when tightening stainless threaded fittings

into CPVC.

If a leak persists, it will be necessary to drain the system, disassemble the threaded

joint, clean the threads and reassemble with a generous amount of Teflon paste

applied to the threads.

No matter how well you drain the system with the pumps, be aware that there will

be liquid in the tubes, manifolds, and chill blocks. This requires special care in

IMPORTANT

It is better to have more water than glycol in the mixture because

water is a better thermal conductor than glycol.

Thread Size

Torque N•m (lb•ft)

Typical Wrench Size

l/4 inch NPT

9,5 N•m (7.0 lb•ft)

15 mm (9/16 in.)

3/8 inch NPT

9,5 N•m (7.0 lb•ft)

19 mm (3/4 in.) and 26 mm (1 in.)

1/2 inch NPT

27 N•m (20 lb•ft)

29 mm (1-1/8 in.)