Rectifier designs, 18 pulse rectifier, Active front end (afe rectifier) – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 18

18

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Chapter 1

Overview of Drive

Rectifier Designs

There are two offered designs for the rectifier of the PowerFlex 7000L drive.

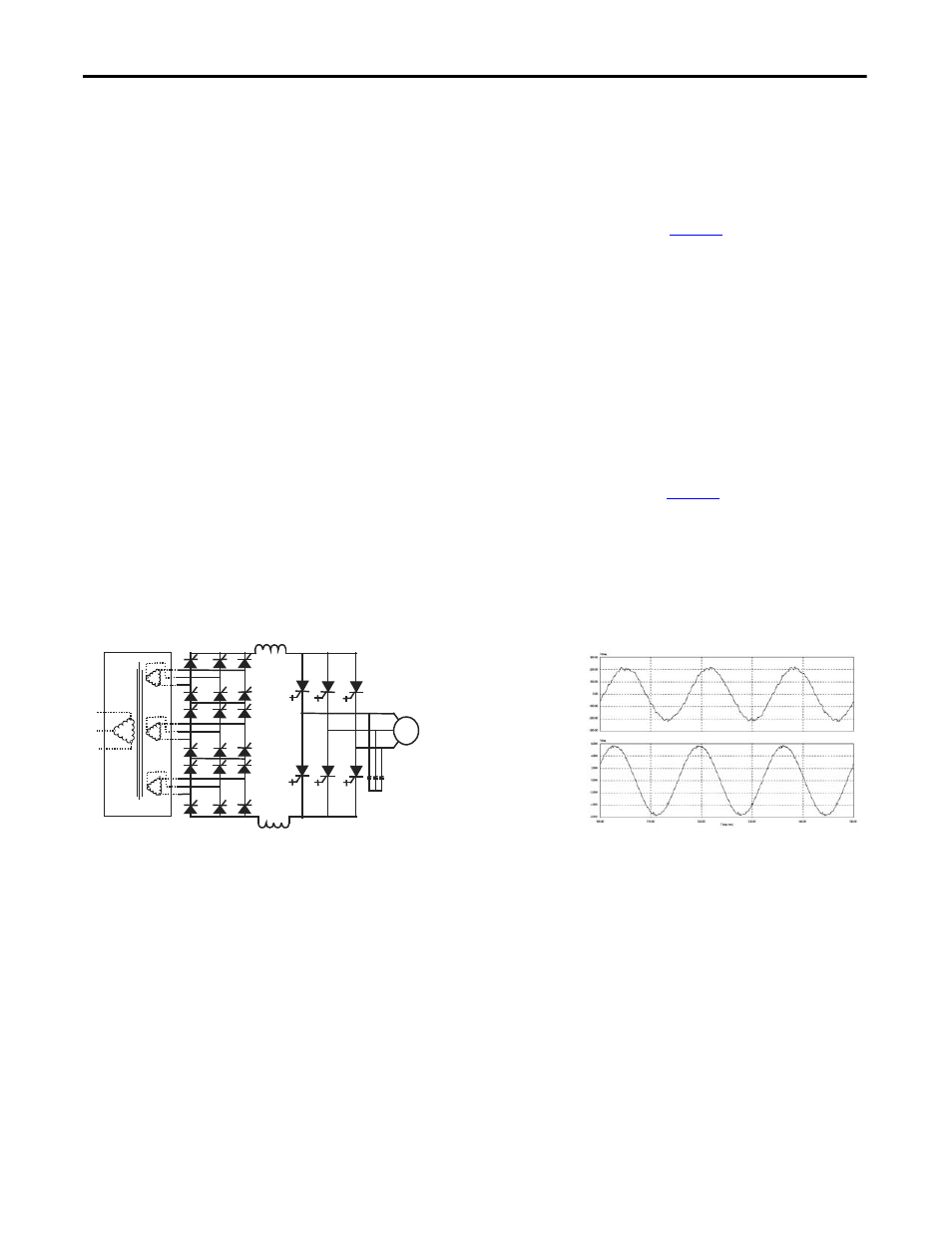

18 Pulse Rectifier

An 18 Pulse phase controlled rectifier is shown in

. In an 18 Pulse

configuration, the IEEE 519-1992 requirements are met in the majority of cases

without the need for passive filters; however, a multi-winding isolation

transformer is required to mitigate the low order harmonics by phase shifting

principles. The 18 Pulse solution is superior to 6- or 12-pulse offerings in terms of

lowering line side harmonics.

Isolation transformers are available in indoor dry type, cast coil, and outdoor oil-

filled designs for maximum flexibility in dealing with floor space, installation

costs, and control room air conditioner loading. (Refer to Specification 80001-

005, Rectifier Duty Transformers, for more details on transformer requirements

and features.)

Sample line current and voltage are also shown in

. The THD of line

current is approximately 5.6%, while the THD of line voltage (line-to-line) is

approximately 2.0%. (THD of line voltage is a function of system impedance.)

The 18 Pulse rectifier consists of one master bridge and two slave bridges and will

always have a total of 18 SCR switching devices.

Figure 2 - 18 Pulse Rectifier and its input waveforms

Active Front End (AFE Rectifier)

An active front end (AFE rectifier) suitable for the PowerFlex 7000L topology is

also commonly called a PWM rectifier. This is particularly attractive since it does

not require an isolation transformer to meet IEEE 519-1992. Most available

technologies in today’s MV market require a multi-winding transformer to

mitigate the unwanted harmonics by phase shifting the transformer secondary

windings. Depending on the topology, the transformer can have up to 15 sets of

secondary windings. Elimination of the isolation transformer reduces capital and

installation costs, saves on valuable floor space, and increases overall system

efficiency.

Line

current

Line-to-line

voltage at PCC