Pipe materials and layout – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 76

76

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Chapter 2

Drive Installation

Pipe Materials and Layout

All material that contacts fluid between the heat exchanger and drive must be

either Schedule 80 CPVC or stainless steel. Rockwell Automation recommends

using stainless steels AISI 304L or 316L to connect the drives to heat exchangers.

Use 304L and 316L welding wire to avoid sensitization of the welded material.

Sensitization due to incorrect welding causes localized corrosion of the welded

area. Pressures expected within a drive are below 75 psi with test pressures of

110 psi.

Schedule 80 CPVC piping may be installed within a climate controlled building

with any outside pipe of stainless steel. Shield CPVC from direct sunlight to

prevent UV damage. Use expansion loops for long pipe runs.

See document CTS-3 "CPVC CTS Products Design and Installation Manual"

from Spears Manufacturing Compan

) for more

information.

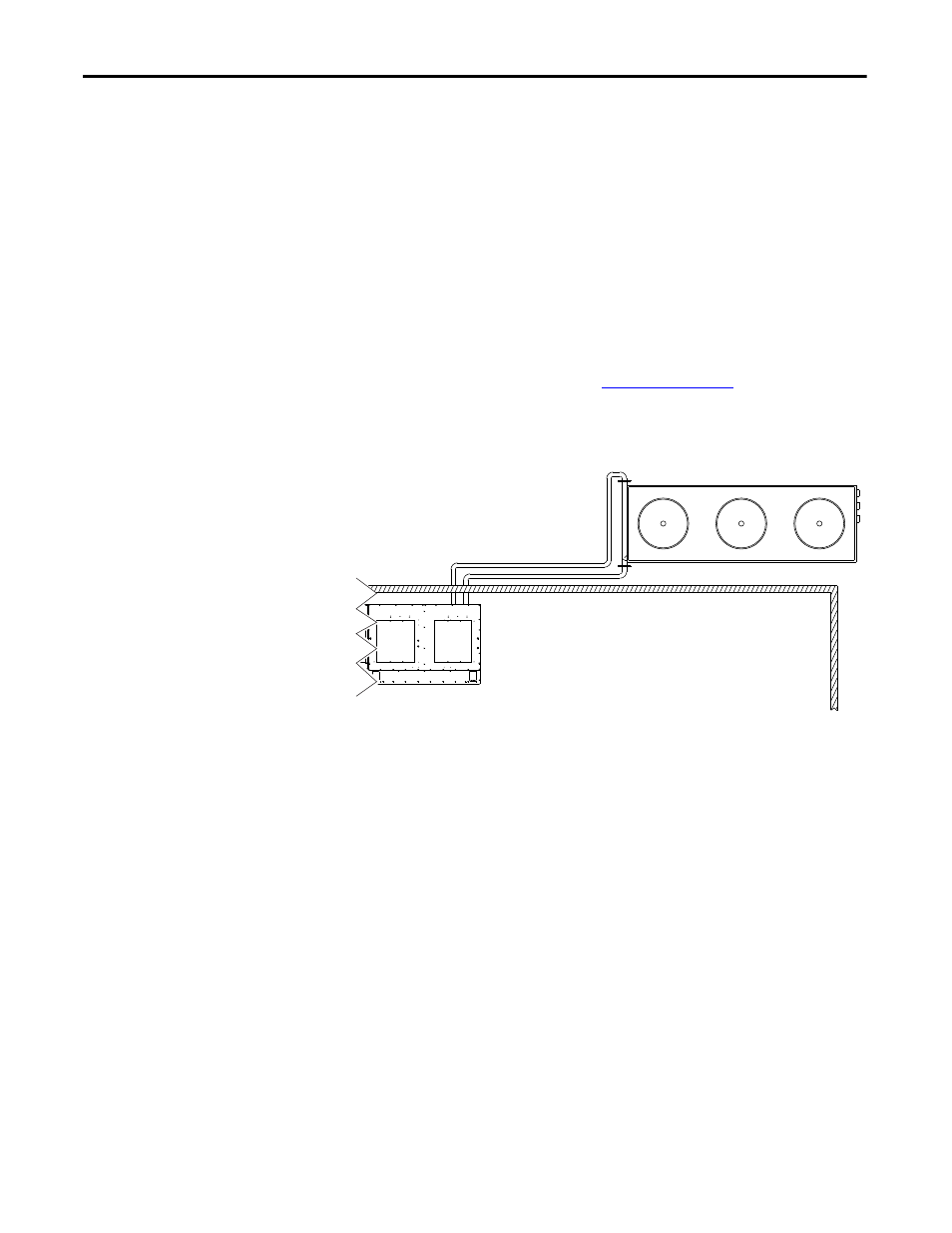

Figure 60 - Plan View of Piping to Heat Exchanger (Piping may vary with exchanger)

Ensure exit flow from the pump cabinet is routed to the inlet flange of the

exchanger.

The estimated flow rate and pressure is printed on the cooling system schematic,

which is posted on the inside of the pumping cabinet door.

The pipes to which connections are made are Schedule 80 CPVC: 38 mm

(1.50 in.) or 50 mm (2.00 in.).

Pump Section

Fluid Cooler