Repair instructions - element testing, Element replacing – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 335

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

335

Component Definition and Maintenance

Chapter 5

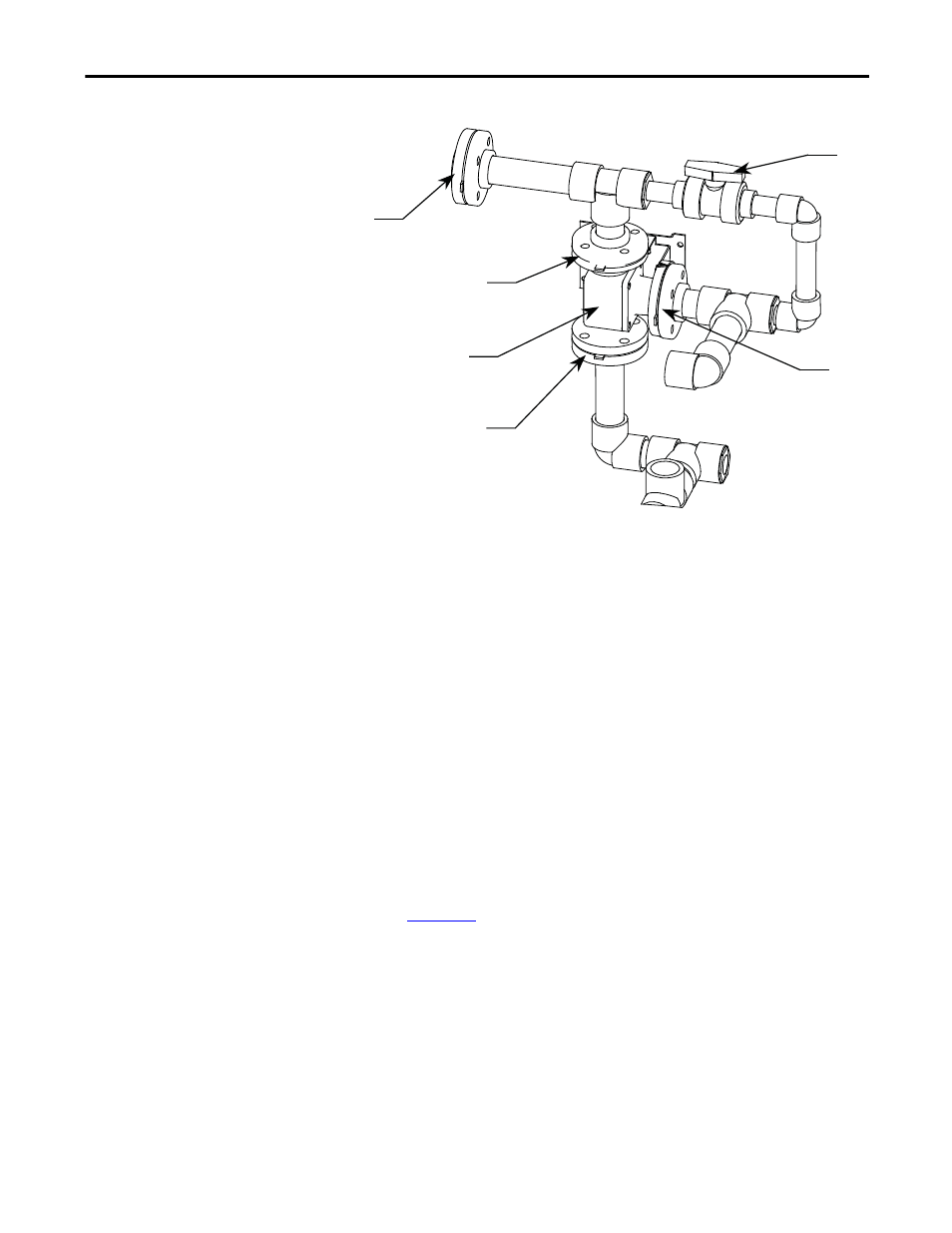

Figure 279 - Thermostatic Valve Replacement

Repair Instructions - Element Testing

Place element in water at a temperature 8 °C...1 °C (15 °F...2 °F) above its nominal

setting and stir water vigorously with the element for five minutes. The

temperature stamped on the side of the element is not the nominal temperature;

it is the temperature at which the element is set to open. The stamped

temperature is usually 6...8 °C (10...15 °F) higher than the nominal. After stirring

vigorously, immediately place the element in the housing. If the element is fully

stroked, the seating and over-travel spring can be felt as it is pushed down. To

determine if the element will close at a specific temperature, place the element in

a bath of water approximately 3 °C (5 °F) below the start to open temperature.

This is the number stamped on the element. Due to the effect of hysteresis, the

element will close 3 °C (5 °F) below the start to open temperature.

Element Replacing

Refer to

.

1.

Remove four cap screws, lock-washers and separate upper housing and

lower housing.

2.

Remove element assembly and seal.

3.

Remove housing gasket. Clean housing sections and remove any scale or

foreign material from seal faces.

4.

Lubricate the new element seal and slide it in place over top of the element

assembly into position shown in section view.

5.

Place new housing gasket in recess of upper housing.

To Heat Exchanger

TV1-C

Thermostatic Valve Housing TV1

TV1-B

TV1-A

V10