Power wiring, Drive line-up status, Cooling system status – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 173

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

173

Commissioning

Chapter 4

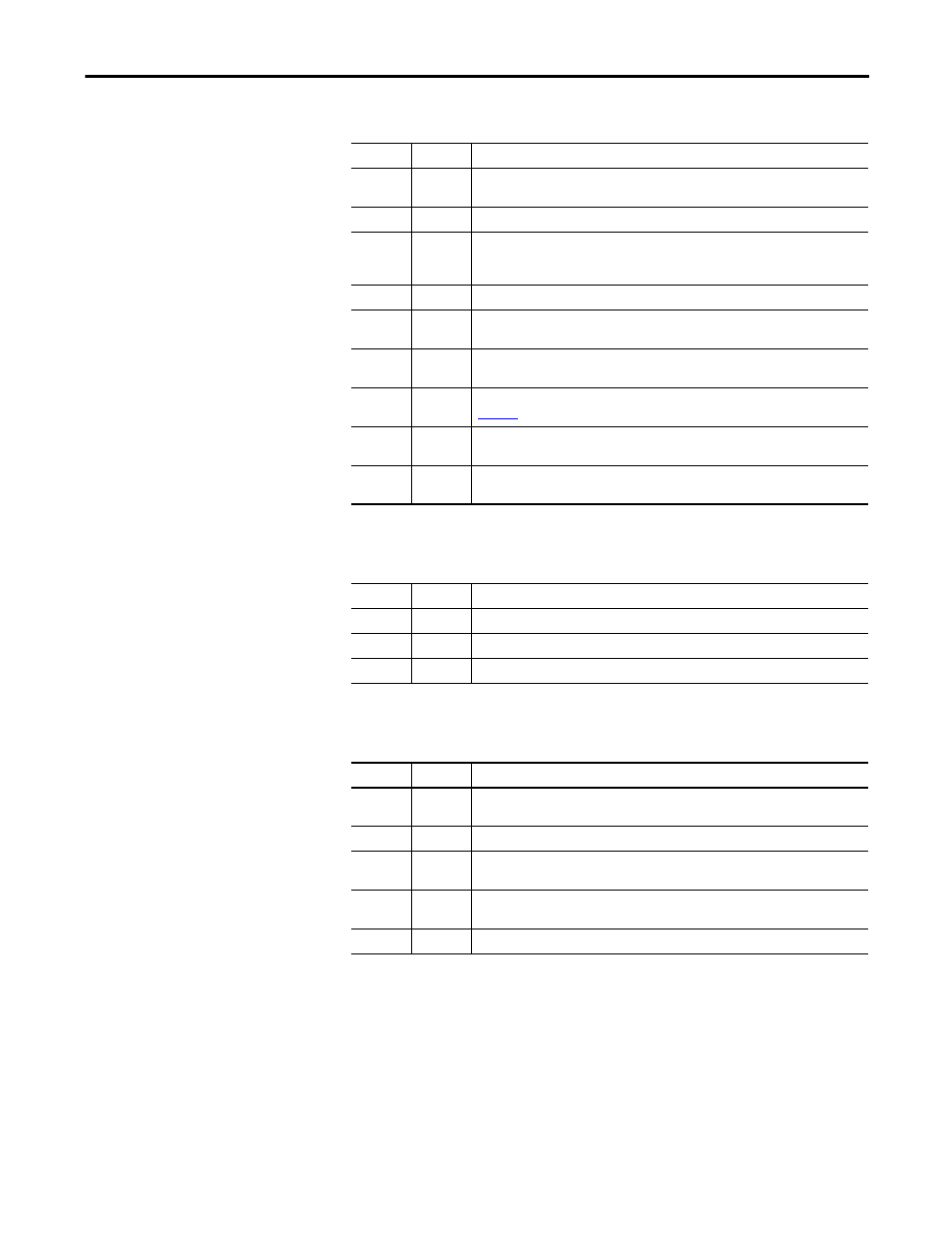

Power Wiring

Drive Line-up Status

Cooling System Status

Initials

Date

The power cable connections to the drive, motor and isolation transformer adhere to CEC,

NEC, IEC or appropriate local standards.

The cable terminations, if stress cones are used, adhere to the appropriate standards.

Appropriate cable insulation levels are adhered to, as per Rockwell Automation

specifications (refer to tables in Chapter 2 of User Manual for Cable Insulation

Requirements).

All shields for shielded cables must be grounded at the source end only.

If shielded cables are spliced, the shield must remain continuous and insulated from

ground.

All wire sizes used are selected by observing all applicable safety and CEC / NEC / IEC

regulations.

All power connections are torqued as per Rockwell Automation Specifications. (See

All customer power cabling has been Meggered or Hi-Pot tested before connecting to drive

system.

Power wiring phase rotation has been verified per the specific electrical diagrams supplied

by Rockwell Automation.

Initials

Date

The medium voltage and low voltage power is available for startup activities.

The motor is uncoupled from the driven load.

The load is available for full load testing.

Initials

Date

The barrel of coolant is present. (Glycol and de-ionized water may not be used in the

future).

The liquid-to-air heat exchanger has been installed and wired (if necessary).

For liquid-to-liquid heat exchangers, the source of cooling water has been connected and

testing.

Piping from teh drive to the heat exchanger has been completed. The piping should be

copper, CPVC, HDPE, or stainless steel. Do not use lead solder for connections.

Piping is clear from construction debris.