Joining shipping splits – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 38

38

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Chapter 2

Drive Installation

The location of the anchor points is provided with the dimension drawing of the

drive.

Install and tighten the anchor bolts. (M12 or 1/2" hardware required).

Engineered bolt systems are required for seismic requirements. Consult factory.

Remove the top lifting angles, retain the hardware.

Install the hardware from the lifting angles in the tapped holes at the top of drive;

this prevents leakage of cooling air as well as keeping dust out of the equipment.

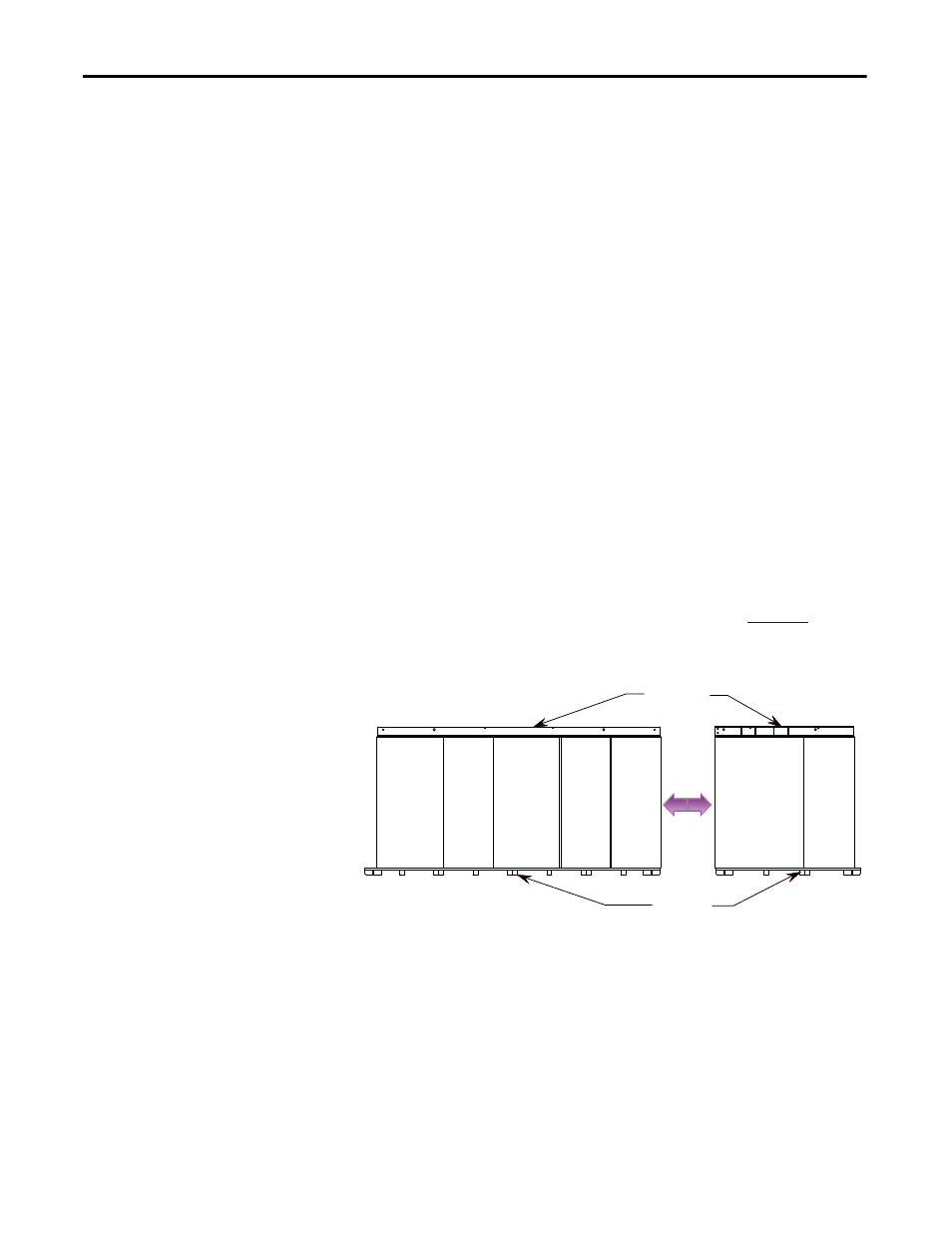

Joining Shipping Splits

The Drive may have been shipped in two or more shipping sections which are to

be connected at installation. It is essential that the surfaces are level. Arrange the

sections per the information provided in the dimension drawings and move the

sections together. Ground bus, power and control connections are to be made per

the electrical diagrams provided. Side sheets of the enclosures are to be joined

with thread forming screws using the available holes.

Liquid-cooled Drives may require joining of the coolant pipes. Some enclosure

ratings may require the addition of silicone sealant where cabinets join together

to prevent the possible ingress of dripping water.

For Direct-to-Drive liquid-cooled 6600V Drives (430A, 495A and 575A rated

current) the Drive will be shipped in two sections as shown in

.

Figure 15 - Typical Split Drive

The 1st section consists of 5 cabinets.

The 2nd section consists of 2 cabinets.

Final placement requires that the 1st and 2nd sections are joined at final

installation site.

LR

CAB

1

CABLE

CAB

2

CONV

CAB

3

CAP

CAB

4

CAP

CAB

5

DC LINK

CHOKE

CAB

6

PUMP

CAB

7

Lifting Angles

Wood Skid

1st SECTION

2nd SECTION