Snubber resistors, Figure 254 – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 306

306

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

Chapter 5

Component Definition and Maintenance

5.

After the PowerCage is securely fastened to the backplane refer to the

appropriate sections to replace all other components.

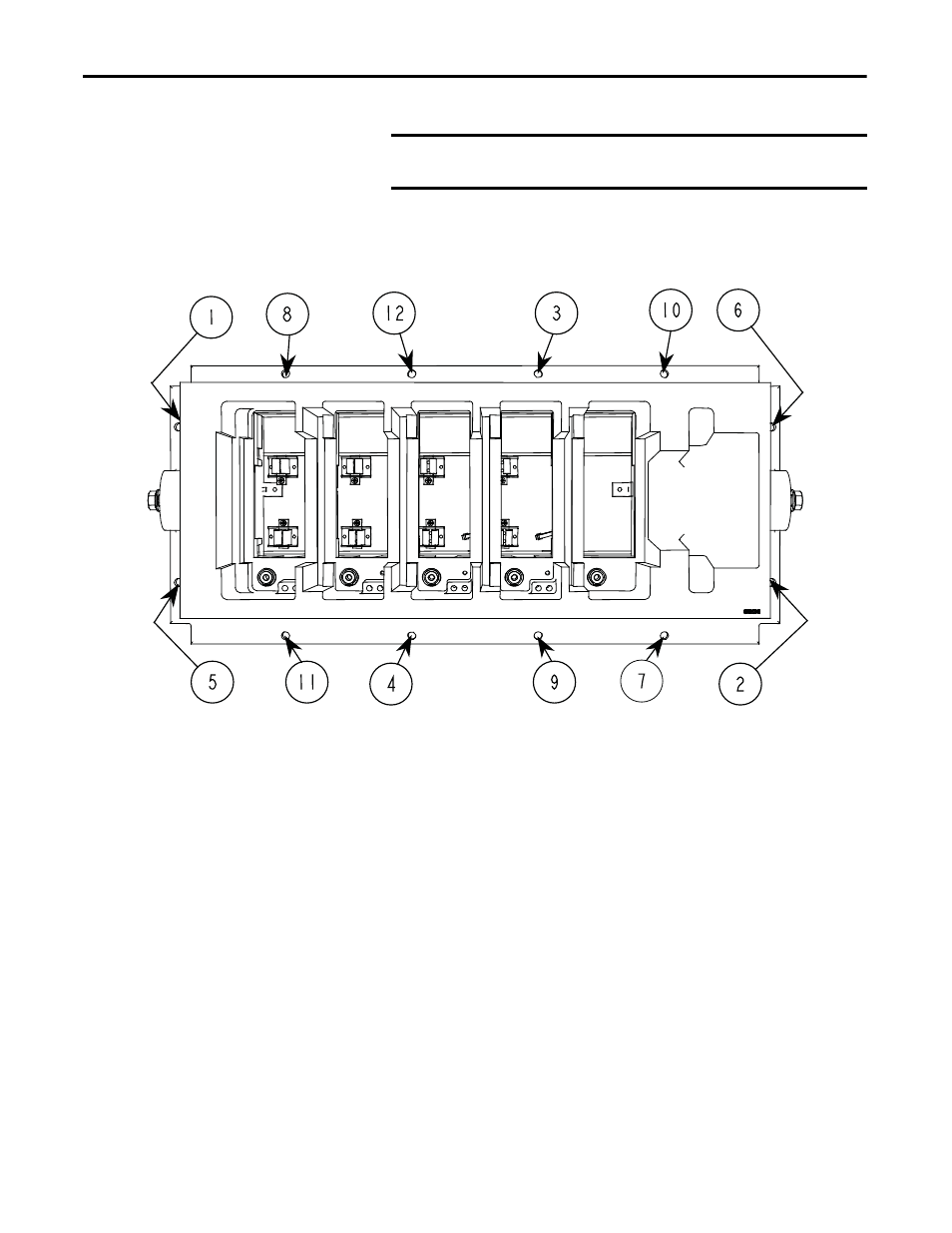

Figure 254 - Typical Torque Sequence

Snubber Resistors

A test point is provided inside the PowerCage to measure the resistance of the

snubber resistor and capacitance of the snubber capacitor. The test point is the

electrical connection between the snubber resistor and snubber capacitor. The

procedure is to place one probe of the multi-meter on the test point and the other

probe on the appropriate chill block to determine the value of the resistor or

capacitor.

Snubber resistors are connected in series with the snubber capacitors. Together

they form a simple RC snubber that is connected across each semiconductor

(SCR or SGCT). The purpose of the snubber circuit is to reduce the dv/dt stress

on the semiconductors and to reduce the switching losses. The snubber resistors

are connected as sets of thick film resistors. The number of resistors depends on

the type of the semiconductor and the configuration and frame size of the drive.

IMPORTANT

When replacing the PowerCage, always be sure all the PowerCage

components are removed.