Heat exchanger checks – Rockwell Automation 7000L PowerFlex Medium Voltage AC Drive (C-Frame) - ForGe Control User Manual

Page 215

Rockwell Automation Publication 7000L-UM301D-EN-P - June 2014

215

Commissioning

Chapter 4

Heat Exchanger Checks

The PowerFlex “C” Frame drive requires a heat exchanger to transfer heat from

the drive coolant to an external medium. There should be connections from the

drive pumping cabinet to the heat exchanger. Ensure that these connections are

completed and attached to the proper locations (inlet / outlet) on both the drive

and the heat exchanger.

These connections should be made from stainless steel.

The customer should not be using lead solder with the connections, as the

coolant will deteriorate this connection over time.

When making connections to the drive from the heat exchanger, ideally the

connections or the heat exchanger should not be at an elevation higher than the

internal drive piping (below inlet of reservoir). This allows the drive to remove

any trapped air in the system. If the heat exchanger is at a higher elevation, then

air release valves should be installed at the highest point.

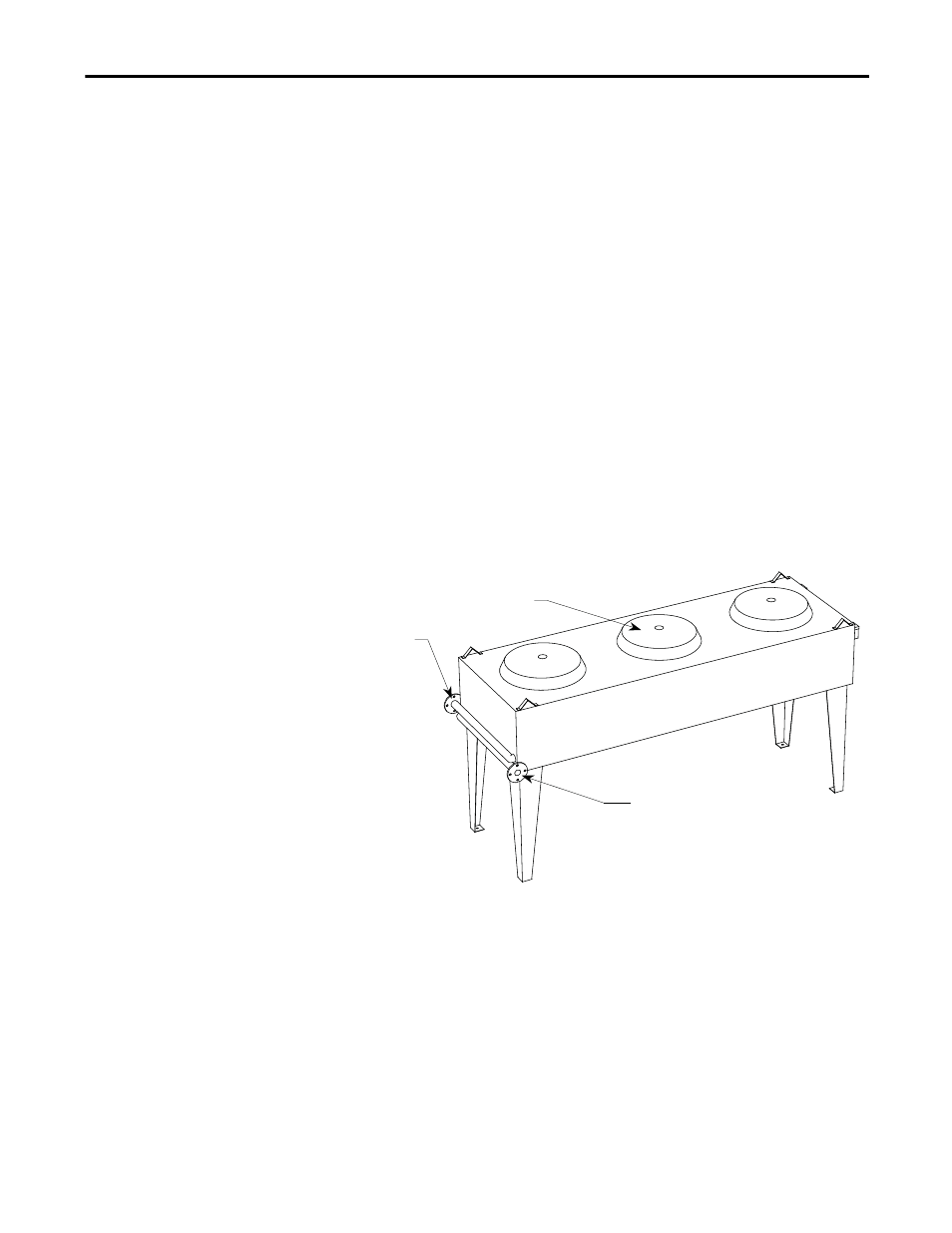

Figure 196 - Typical Liquid-to-air Heat Exchanger

The tubing to the heat exchanger should have been cleaned by the installation

personnel. If they are still in the process of installation you should verify that the

piping will be cleaned. Otherwise the filling process will probably produce a lot

of debris in the first mesh filter and may require several cleanings.

On a liquid-to-air heat exchanger, there will be fans on the heat exchanger to

move the air over the cooling tubes within the exchanger. Ensure these fans are

wired properly per the electrical print.

On a liquid-to-liquid heat exchanger, process water will be required to transfer

heat from the drive coolant. The water temperature, pressure and flow rate are as

TIP

The largest heat exchanger is 287 cm (113 inches) tall.

Fan

Coolant Inlet

Coolant Outlet