Fault diagnosis with test functions – Teledyne 6200E - Sulfides Analyzer User Manual

Page 242

TROUBLESHOOTING & REPAIR

Model 6200E Instruction Manual

242

M6200E Rev: A1

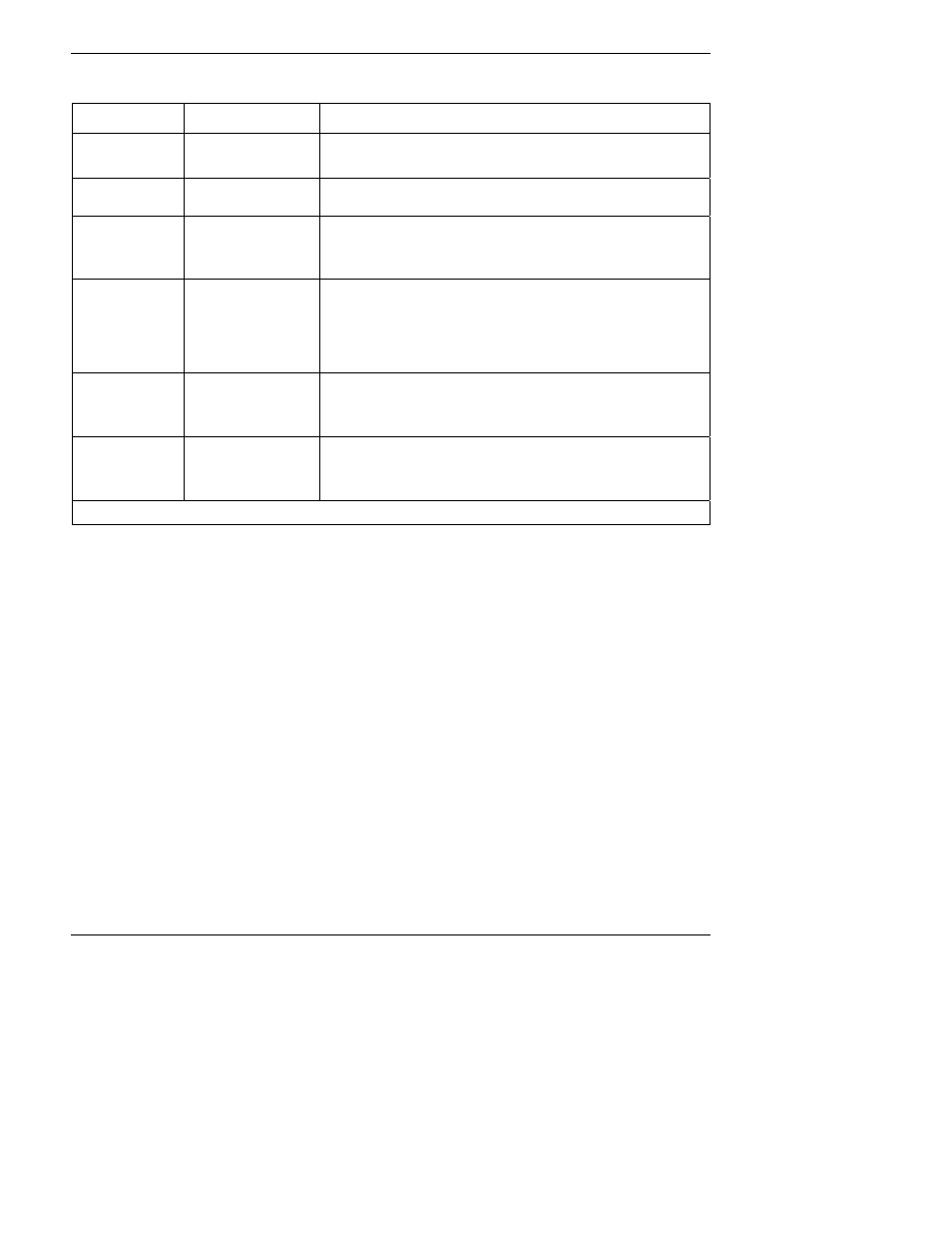

Table 11-1: Warning Messages - Indicated Failures (cont.)

WARNING

MESSAGE

FAULT CONDITION

POSSIBLE CAUSES

REAR BOARD

NOT DET

Mother Board not

detected on power up.

Warning only appears on serial i/o com port(s)

Front panel display will be frozen, blank or will not respond.

Massive failure of mother board.

RELAY BOARD

WARN

The CPU cannot

communicate with the

Relay Board.

I

2

C buss failure

Failed relay board

Loose connectors/wiring

SAMPLE FLOW

WARN

Sample flow rate is <

500 cc/min or > 1000

cc/min.

Failed sample pump

Blocked sample inlet/gas line

Dirty particulate filter

Leak downstream of critical flow orifice

Failed flow sensor/circuitry

SAMPLE PRES

WARN

Sample Pressure is

<10 in-Hg or

> 35 in-Hg

1

If sample pressure is < 10 in-hg:

o

Blocked particulate filter

o

Blocked sample inlet/gas line

o

Failed pressure sensor/circuitry

If sample pressure is > 35 in-hg:

o

Blocked vent line on pressurized sample/zero/span gas supply

o

Bad pressure sensor/circuitry

SYSTEM RESET

The computer has

rebooted.

This message occurs at power on.

If it is confirmed that power has not been interrupted:

Failed +5 VDC power,

Fatal error caused software to restart

Loose connector/wiring

UV LAMP

WARNING

The UV lamp intensity

is < 600mV or > 4995

mV

UV lamp is bad

Reference detector is bad

Mother board analog sensor input circuitry has failed.

Fogged or damaged lenses/filters in UV light path

A/D converter circuitry failure

1

Normally 29.92 in-Hg at sea level decreasing at 1 in-Hg per 1000 ft of altitude

(with no flow – pump disconnected).

11.1.2. Fault Diagnosis with Test Functions

Besides being useful as predictive diagnostic tools, the TEST functions, viewable from the front

panel, can be used to isolate and identify many operational problems when combined with a

thorough understanding of the analyzer’s theory of operation (Section 10). We recommend use of

the APICOM remote control program to download, graph and archive TEST data for analysis, and

long-term monitoring of diagnostic data.

The acceptable ranges for these test functions are listed in Table A-3 in Appendix A-3. The actual

values for these test functions on checkout at the factory were also listed in the Final Test and

Validation Data Sheet, which was shipped with the instrument. Values outside the acceptable

ranges indicate a failure of one or more of the analyzer’s subsystems. Functions with values that

are within the acceptable range but have significantly changed from the measurements recorded

on the factory data sheet may also indicate a failure or a maintenance item. A problem report

worksheet has been provided in Appendix C to assist in recording the value of these test

functions. The following table (Table 11-2) contains some of the more common causes for these

values to be out of range.