So2 scrubber, Pneumatic sensors, Sample pressure sensor – Teledyne 6200E - Sulfides Analyzer User Manual

Page 216: Scrubber

Theory Of Operation

Model 6200E Instruction Manual

216

M6200E Rev: A1

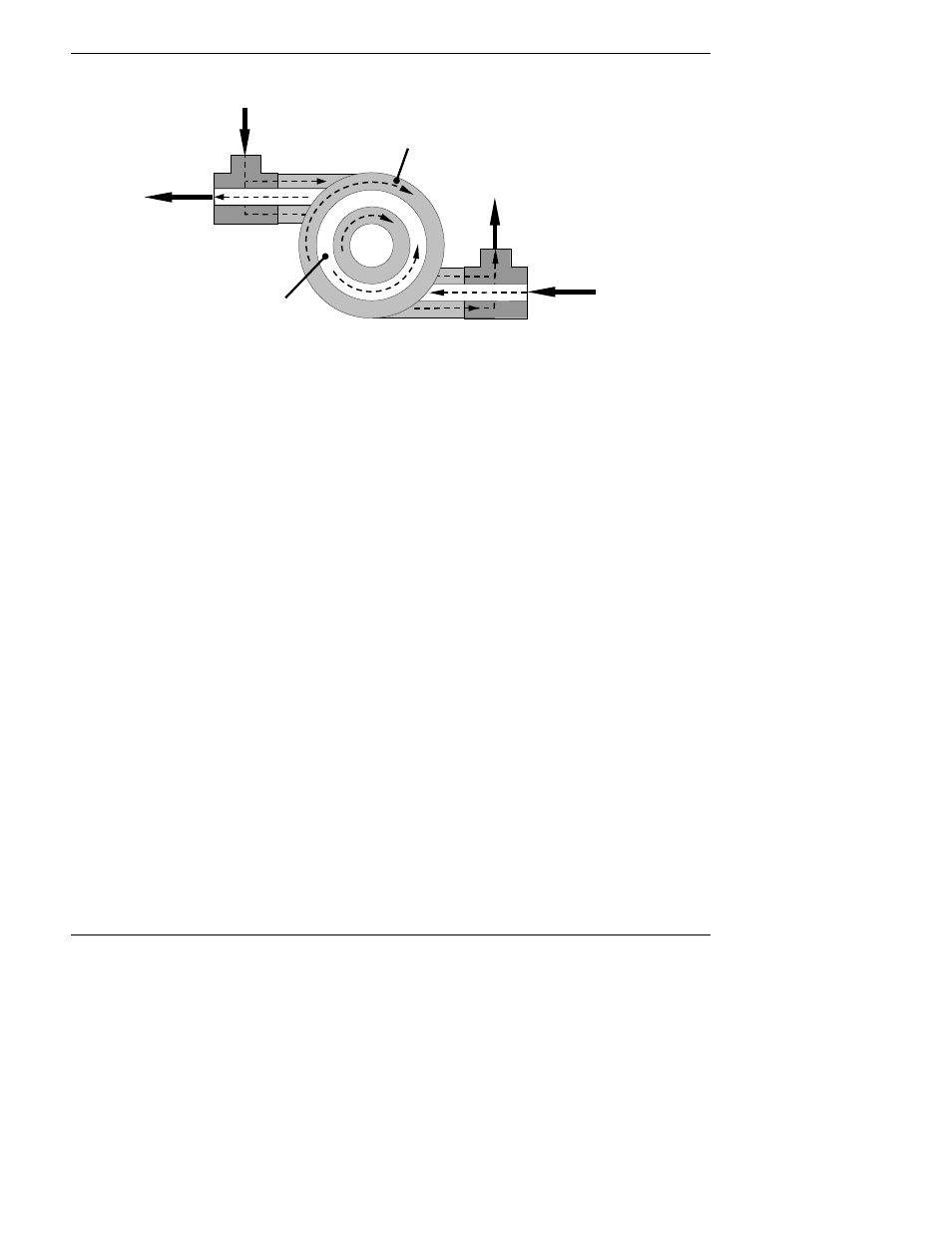

INNER

TUBE

(Ambient Air)

OUTER TUBE

(Clean Air)

SAMPLE AIR

FROM

PARTICULATE FILTER

CLEANED

SAMPLE AIR

TO

SAMPLE

CHAMBER

CLEAN

PURGE AIR

FROM

VACUUM MANIFOLD

USED PURGE AIR

TO

PUMP

AND

EXHAUST PORT

Figure 10-9: M6200E Hydrocarbon Scrubber (Kicker)

In the M6200E some of the cleaned air from the inner tube is returned to be used as the purge

gas in the outer tube (Figure 10-9). This means that when the analyzer is first started, the

concentration gradient between the inner and outer tubes is not very large and the scrubber’s

efficiency is relatively low. When the instrument is turned on after having been off for more than

30 minutes, it takes a certain amount of time for the gradient to become large enough for the

scrubber to adequately remove hydrocarbons from the sample air.

10.3.6. SO

2

Scrubber

In order to ensure that no ambient SO

2

interferes with the analyzer’s H

2

S measurement the

sample gas stream is passed through a chemical scrubber that removes SO

2

from the sample

stream before it is passed though the catalytic converter (see Figure 10-7).

The SO

2

scrubber is a Teflon encased, stand-alone unit containing a room-temperature catalyst

tube mounted in the front right side of the analyzer case (see Figure 3.8) near the instrument’s

on/off switch.

The SO

2

scrubber material is consumed as it removes SO

2

. If the expected concentrations of SO

2

are very high, the lifetime of the scrubber will be short. The expected life of the scrubber is

approximately 1000 ppm-hours. See Section 9.3.3 for information on when and how to replace

the SO

2

scrubber material)

10.3.7. Pneumatic Sensors

The M6200E uses two pneumatic sensors to verify gas streams. These sensors are located on a

printed circuit assembly, called the pneumatic pressure/flow sensor board.

10.3.7.1. Sample Pressure Sensor

An absolute pressure transducer plumbed to the input of the analyzer’s sample chamber is used to

measure the pressure of the sample gas before it enters the chamber. This upstream used to

validate the critical flow condition (2:1 pressure ratio) through the instrument’s critical flow orifice

(Section 10.3.3). Also, if the temperature/pressure compensation (TPC) feature is turned on