Flow rate control, Critical flow orifice – Teledyne 6200E - Sulfides Analyzer User Manual

Page 214

Theory Of Operation

Model 6200E Instruction Manual

214

M6200E Rev: A1

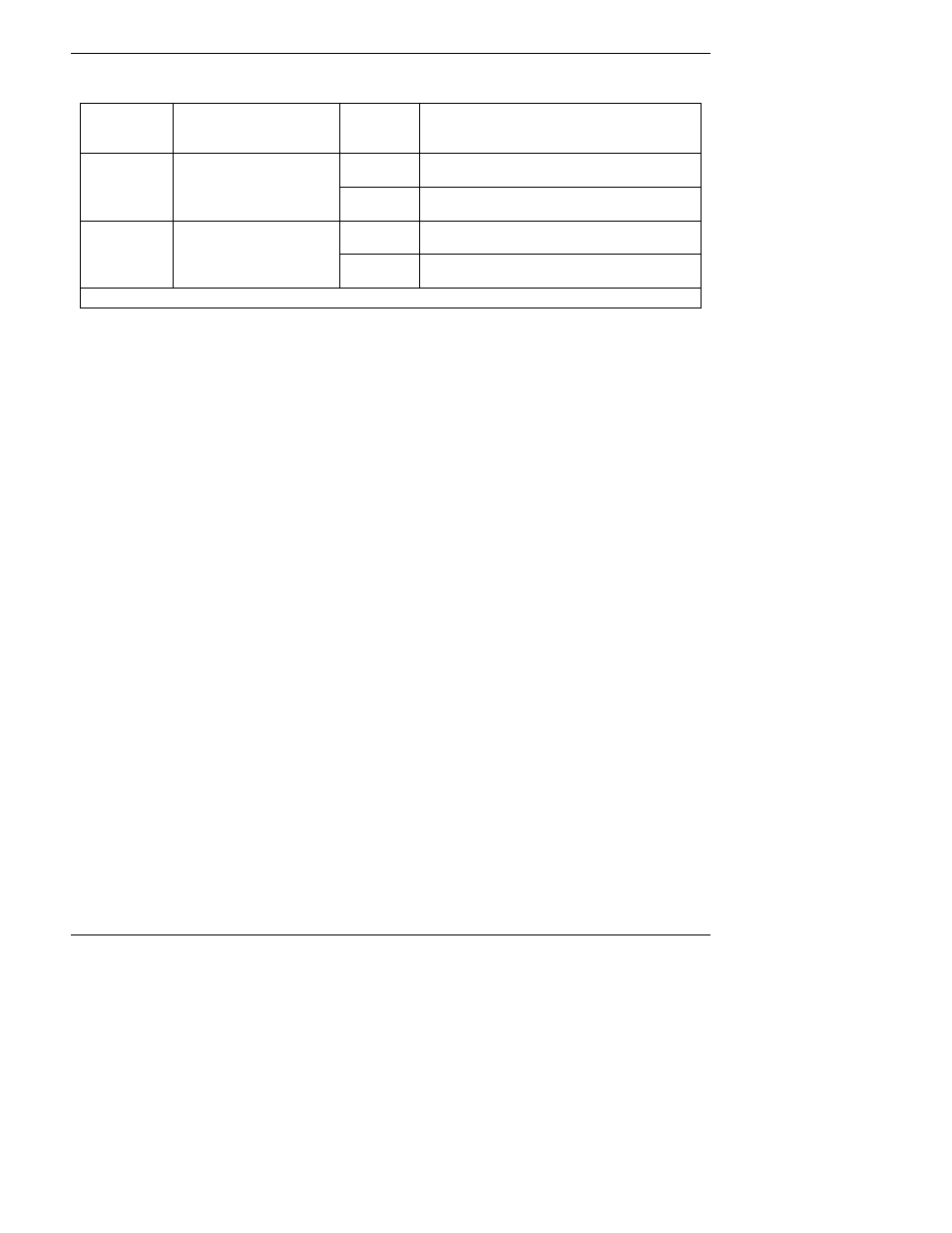

Table 10-1: M6200E Multigas Valve Cycle-Phases

Gas Mode

H

2

S

Æ SO

2

Valve Status

Default

Time

Settings

Activity

0 – 3

minutes

Wait period. Ensures sample chamber has

been flushed of previous gas.

H

2

S

Gas stream directed

through scrubber and

converter

3 – 10 m

Analyzer measures florescence in sample

chamber

0 – 3

minutes

Wait period (dwell time). Ensures sample

chamber has been flushed of previous gas.

SO

2

Gas stream bypasses

through scrubber and

converter

3 – 10 m

Analyzer measures florescence in sample

chamber

Cycle repeats every ~20Minuites

The timing of the above cycle is set by two variables (see Appendix A-2), MEASURE_PERIOD,

which sets the total dwell time for each gas mode, and MEASURE_DELAY which sets the wait

period before the instrument begins making measurements after the gas mode has been switch.

10.3.3. Flow Rate Control

The Model 6200E uses a special flow control assembly located in the exhaust vacuum manifold

(Figure 10-7) to maintain a constant flow rate of the sample gas through the instrument. This

assembly consists of:

A critical flow orifice.

Two o-rings: Located just before and after the critical flow orifice, the o-rings seal the gap

between the walls of assembly housing and the critical flow orifice.

A spring: Applies mechanical force needed to form the seal between the o-rings, the critical flow

orifice and the assembly housing.

10.3.3.1. Critical Flow Orifice

The most important component of this flow control assembly is the critical flow orifice.

Critical flow orifices are a remarkably simple way to regulate stable gas flow rates. They operate

without moving parts by taking advantage of the laws of fluid dynamics. By restricting the flow of

gas though the orifice, a pressure differential is created. This pressure differential combined with

the action of the analyzer’s external pump draws the gas through the orifice.

As the pressure on the downstream side of the orifice (the pump side) continues to drop, the

speed that the gas flows though the orifice continues to rise. Once the ratio of upstream pressure

to downstream pressure is greater than 2:1, the velocity of the gas through the orifice reaches

the speed of sound. As long as that ratio stays at least 2:1 the gas flow rate is unaffected by any

fluctuations, surges, or changes in downstream pressure because such variations only travel at

the speed of sound themselves and are therefore cancelled out by the sonic shockwave at the

downstream exit of the critical flow orifice.