Predictive diagnostics – Teledyne 6200E - Sulfides Analyzer User Manual

Page 192

Instrument Maintenance

Model 6200E Instruction Manual

192

M6200E Rev: A1

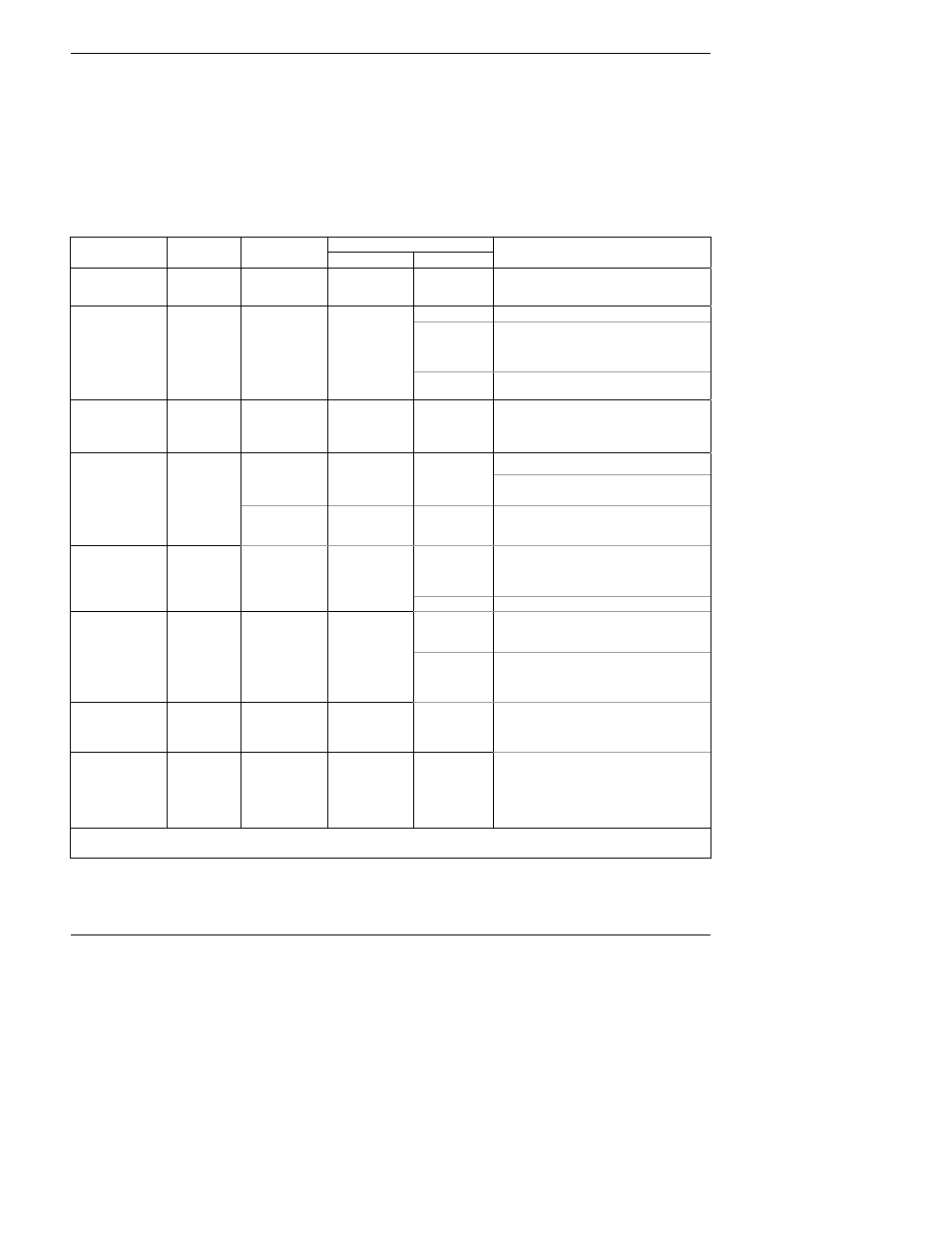

9.2. Predictive Diagnostics

The analyzer’s test functions can be used to predict failures by looking at trends in their values.

The current value of these functions can be viewed via the front panel, recorded via the iDAS

system (see Section 6.11) or even downloaded via the internet from a remote location using

Teledyne Analytical Instruments’ APICOM control software can be used to download and review

this data (see Section 6.12.2.8).

Table 9-2: Predictive Uses for Test Functions

BEHAVIOR

TEST

FUNCTION

iDAS

FUNCTION

CONDITION

EXPECTED ACTUAL

INTERPRETATION

H2S STB

1

N/A Zero

Gas

≤ 1 ppb with

zero air

Increasing

• Pneumatic Leaks – instrument &

sample system

• Detector deteriorating

Fluctuating

• Developing leak in pneumatic system

Slowly

increasing

• Flow path is clogging up.

- Check critical flow orifice &

sintered filter.

- Replace particulate filter

PRES SMPPRS

sample gas

Constant

within

atmospheric

changes

Slowly

decreasing

• Developing leak in pneumatic system

to vacuum (developing valve failure)

DRK PMT

DRKPMT

PMT output

when UV

Lamp shutter

closed

Constant

within ±20 of

check-out

value

Significantly

increasing

• PMT cooler failure

• Shutter Failure

• Change in instrument response

At span with

IZS option

installed

Constant

response

from day to

day

Decreasing

over time

• Degradation of IZS permeation tube

SO

2

Concentration

CONC1

Standard

configuration

at span

stable for

constant

concentration

Decreasing

over time

• Drift of instrument response; UV

Lamp output is excessively low;

clean RCEL window

Slowly

Decreasing

• Flow path is clogging up.

- Check critical flow orifice &

sintered filter.

- Replace particulate filter

SAMP FL

SMPFLW

Standard

Operation

Stable

Fluctuating

• Leak in gas flow path.

Fluctuating

or Slowly

increasing

• UV detector wearing out

• UV source Filter developing pin holes

LAMP RATIO

LAMPR

Standard

Operation

Stable and

near 100%

Slowly

decreasing

• UV detector wearing out

• Opaque oxides building up on UV

source Filter

• UV lamp aging

H2S OFFS

1

OFSET1

During Zero

Cal

Stable

Slowly

increasing or

decreasing

• Bad PMT

• Failed HVPS

• Leak in sample gas flow

• Contamination in zero gas source.

H2S SLOPE

1

SLOPE1

During Span

Cal

Stable

Slowly

increasing or

decreasing

• UV lamp aging

• UV detector wearing out

• Leak in Sample gas or calibration gas

flow path

• Deterioration / contamination of

calibration gas source(s)

1

Shown as they appear when analyzer is in H

2

S mode. In SO

2

mode appear as SO2 OFFS & SO2 SLOPE. In multigas

mode, both versions appear.