Sample particulate filter, Hydrocarbon scrubber (kicker) – Teledyne 6200E - Sulfides Analyzer User Manual

Page 215

Model 6200E Instruction Manual

Theory Of Operation

M6200E Rev: A1

215

SPRING

O-RINGS

FILTER

CRITICAL

FLOW

ORIFICE

AREA OF

LOW

PRESSURE

AREA OF

HIGH

PRESSURE

Sonic

Shockwave

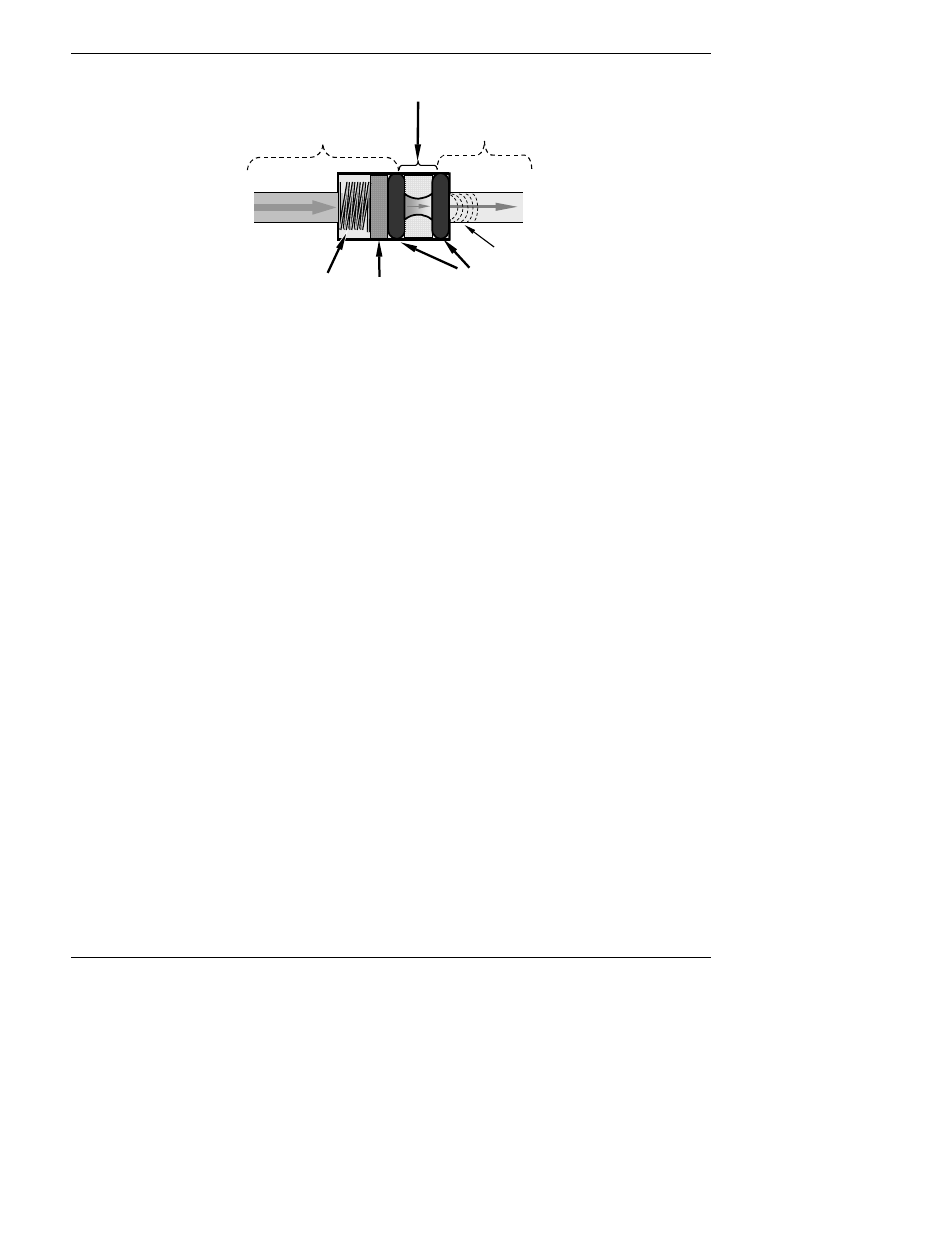

Figure 10-8: Typical Flow Control Assembly with Critical Flow Orifice

The actual flow rate of gas through the orifice (volume of gas per unit of time), depends on the

size and shape of the aperture in the orifice. The larger the hole, the more gas molecules, moving

at the speed of sound, pass through the orifice.

The result is that he flow rate of the gas is unaffected by degradations in pump efficiency due to

age.

The critical flow orifice used in the Model 6200E is designed to provide a flow rate of 650 cm

3

/min.

10.3.4. Sample Particulate Filter

To remove particles in the sample gas, the analyzer is equipped with a Teflon membrane filter of

47 mm diameter (also referred to as the sample filter) with a 1 µm pore size. The filter is

accessible through the front panel, which folds down, and should be changed according to the

suggested maintenance schedule in Table 9-1.

10.3.5. Hydrocarbon Scrubber (Kicker)

It is very important to make sure the air supplied to sample the chamber is clear of hydrocarbons.

To accomplish this task the M6200E uses a single tube permeation scrubber. The scrubber

consists of a single tube of a specialized plastic that absorbs hydrocarbons very well. This tube is

located within the outer flexible plastic tube shell. As gas flows through the inner tube,

hydrocarbons are absorbed into the membrane walls. and transported through the membrane wall

and into the hydrocarbon free, purge gas flowing through the outer tube. This process is driven by

the hydrocarbon partial pressure gradient between the inner and outer tubes.