Teledyne 6200E - Sulfides Analyzer User Manual

Page 180

EPA Protocol Calibration

Model 6200E Instruction Manual

180

M6200E Rev: A1

sampling and through as much of the ambient air inlet system as is practicable. If the Instrument

will be used on more than one range (i.e. IND or AUTO ranges), it should be calibrated

separately on each applicable range. Calibration documentation should be maintained with each

analyzer and also in a central backup file.

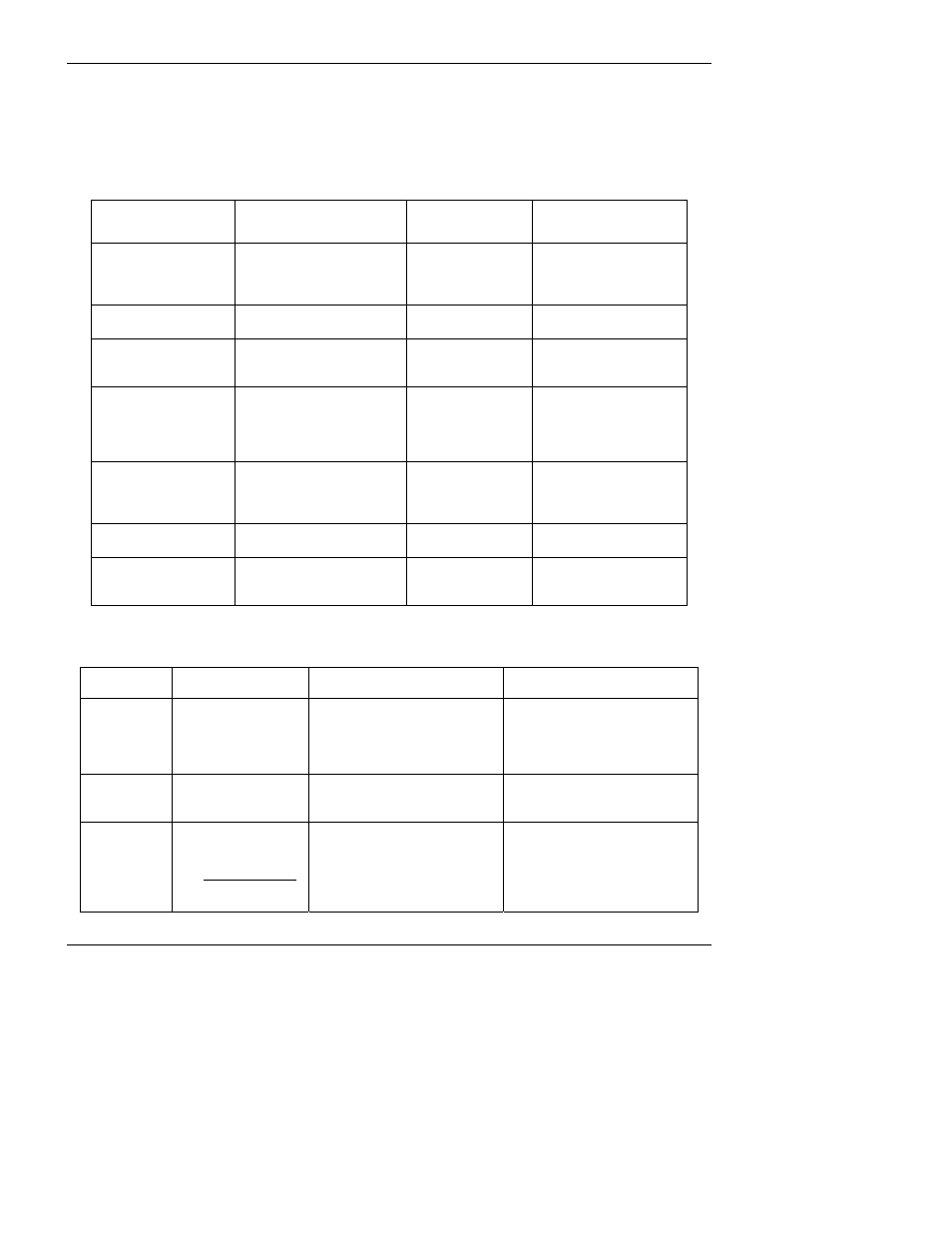

Table 8-1: Activity Matrix for Calibration Equipment & Supplies

EQUIPMENT/SUPPLIES

ACCEPTANCE LIMITS

FREQUENCY AND

METHOD OF

MEASUREMENT

ACTION IF

REQUIREMENTS ARE

NOT MET

Recorder

Compatible with output

signal of analyzer; min.

chart width of 150 mm (6

in) is recommended

Check upon receipt Return equipment to

supplier

Sample Line And

Manifold

Constructed of PTFE or

glass

Check upon receipt Return equipment to

supplier

Calibration Equipment Meets guidelines of

reference 1 and Section

2.3.2 (Q.A. Handbook)

See Section 2.3.9

(Q.A. Handbook)

Return equipment/

supplies to supplier or

take corrective action

Working Standard SO

2

Cylinder Gas Or SO

2

Permeation Tube

Traceable to NIST-SRM

meets limits in traceability

protocol for accuracy and

stability (Section 2.0.7,

Q.A. Handbook)

Analyzed against

NIST-SRM; see

protocol in Section

2.0.7, Q.A.

Handbook

Obtain new working

standard and check for

traceability

Zero Air

Clean dry ambient air, free

of contaminants that cause

detectable response with

the SO

2

analyzer.

See Section 2.9.2

(Q.A. Handbook)

Obtain air from another

source or regenerate.

Record Form

Develop standard forms

N/A

Revise forms as

appropriate

Audit Equipment

Must not be the same as

used for calibration

System must be

checked out against

known standards

Locate problem and

correct or return to

supplier

Table 8-2: Activity Matrix for Calibration Procedure

EQUIPMENT/

SUPPLIES

ACCEPTANCE LIMITS

FREQUENCY AND METHOD OF

MEASUREMENT

ACTION IF REQUIREMENTS ARE

NOT MET

Calibration

Gases

NIST traceable

Assayed against an NIST-SRM

semi-annually, Sec. 2.0.7,

(Q.A. Handbook)

Working gas standard is

unstable, and/or measurement

method is out of control; take

corrective action such as

obtaining new calibration gas.

Dilution Gas Zero air, free of

contaminants

See Section 2.9.2 (Q.A.

Manual)

Return to supplier or take

appropriate action with

generation system

Multi-Point

Calibration

Use calibration

procedure in Subsec.

2.2 (Q.A. Handbook);

also Federal Register

Perform at least once every

quarter or anytime a level span

check indicates a discrepancy,

or after maintenance which

may affect the calibration;

Subsec 2.5 (Q.A. Manual)

Repeat the calibration