3 calculation for power capacity – IAI America MSEP User Manual

Page 31

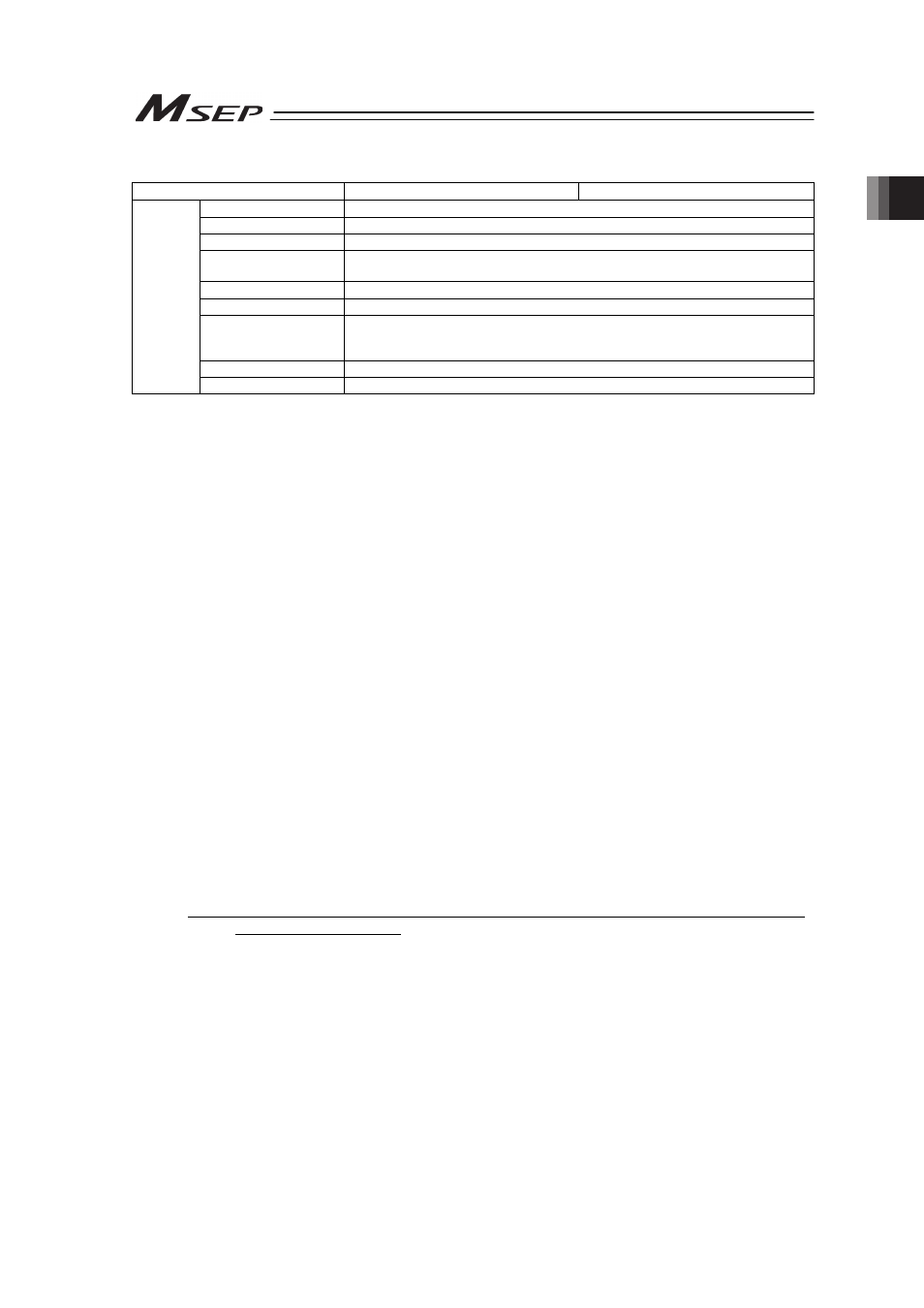

Chapter 1 Specifications Check

23

Specification Item

Driver for Servo Motor

Driver for Pulse Motor

Ambient Temperature

0 to 40qC

Ambient Humidity

85%RH or less (non-condensing)

Ambient Environment

[Refer to Installation Environment]

Ambient Storage

Temperature

-20 to 70qC (0 to 40qC for absolute battery)

Ambient Storage Humidity 85%RH or less (non-condensing)

Usable Altitude

1000m or lower above sea level

Vibration Durability

Frequency 10 to 57Hz / Swing width: 0.075mm

Frequency 57 to 150Hz / Acceleration: 9.8m/s

2

XYZ Each direction Sweep time: 10 min. Number of sweep: 10 times

Shock Resistance

150mm/s

2

11ms Semi-sine wave pulse three times to each of the directions X, Y and Z

Environment

Protection Class

IP20

Note 1 Maximum current draw is realized during the excitation phase following the initial servo power ON. (Normal: Approx.

1 to 2 sec, MAX: 10 sec).

Note 2 The current is maximized at the excitation phase detection conducted in the first servo-on process after the power is

supplied (ordinary 100ms). However, approximately 6A current flows at the recovery (when the drive power is

supplied) from an emergency stop (approx. 1 to 2ms).

Note 3 For servo motor, the over-current protection is triggered at 1.4 times the maximum load current.

Note 4 It is not applicable for the high output setting even if RCP4 is connected.

1.3 Calculation for Power Capacity

For the calculation of 24V DC power capacity, figure out the numbers for (1) to (6) below, and

then follow Step (7).

(1) Control Power Current Consumption : 0.8A ·······································································1)

(2) Motor Power Current Consumption :

Add the total motor current consumption of all connected actuators.·································2)

(3) Current Consumption at Excitation Phase Detection :

Add the inrush current for all connected axes. ···································································3)

(4) Add the Control Power Inrush Current : Number of slots × 5A each. ·································4)

(5) Add the Motor Power Inrush Current : Number of slots × 10A each. ·································5)

(6) Current consumption of brake power supply : Number of actuators with brake × 0.15A····6)

(7) Selection of Power Supply :

Usually, the rated current is to be approximately 1.3 times higher than the total of Control

Power (1) and Motor Power (2) and brake power (6) above considering approximately 30%

of margin to the load current. However, considering the inrush currents [excitation (3),

control (4) and motor power (5)], even though it is a short time, select a power supply with

“sufficient peak load capacity. High cumulative inrush currents can be avoided by taking

precautions to phase the initial servo ON condition and e-stop recovery so that they occur

at different times. If a power supply with insufficient peak capacity is utilized, voltage

drooping may occur. This may present issues with power supplies providing remote sensing

functionality.

(Note) Ensure motor and control power supplies reference the same potential when using

multiple power supplies.

(Reference) Selection of Power Supply Protection Circuit Breaker

It is recommended that the power supply protection is conducted on the primary side (AC

power side) of the 24V DC power supply unit.

When selecting the protection breaker, consider the rated cutoff current of the circuit breaker so

a cutoff is surely performed even in the case of inrush current of 24V DC power supply unit or a

short-circuit of the power supply.

• Rated Breaking Current > Short-circuit Current = Primary Power Supply Capacity/Power

Voltage

• (Reference) In-rush Current of IAI Power Supply Unit PS241 = 50 to 60A, 3msec